GHBWNY

Well-Known Member

It hasn't been until doing some recent reading that I suspect I have under-aerated my beers since starting a year ago. Curious as to method(s) others use to aerate, and what their aerated wort looks like, etc..

I usually pour cooled wort through a strainer into ferm bucket which already has a couple gallons of cool water in it. Takes about 6-8 pours, de-clogging strainer along the way. Then pour topoff water into ferm bucket to bring it up 5 gal., stirring to mix it to get stable temp and OG reading. At pitching I stir yeast in. But that's pretty much it for my aeration routine.

I'm reading that aeration should be so vigorous that 2" of foam should be forming on top. If this is true, I've definitely fallen far short of adequate aeration, which could explain a few things over the year re: different beers.

I usually pour cooled wort through a strainer into ferm bucket which already has a couple gallons of cool water in it. Takes about 6-8 pours, de-clogging strainer along the way. Then pour topoff water into ferm bucket to bring it up 5 gal., stirring to mix it to get stable temp and OG reading. At pitching I stir yeast in. But that's pretty much it for my aeration routine.

I'm reading that aeration should be so vigorous that 2" of foam should be forming on top. If this is true, I've definitely fallen far short of adequate aeration, which could explain a few things over the year re: different beers.

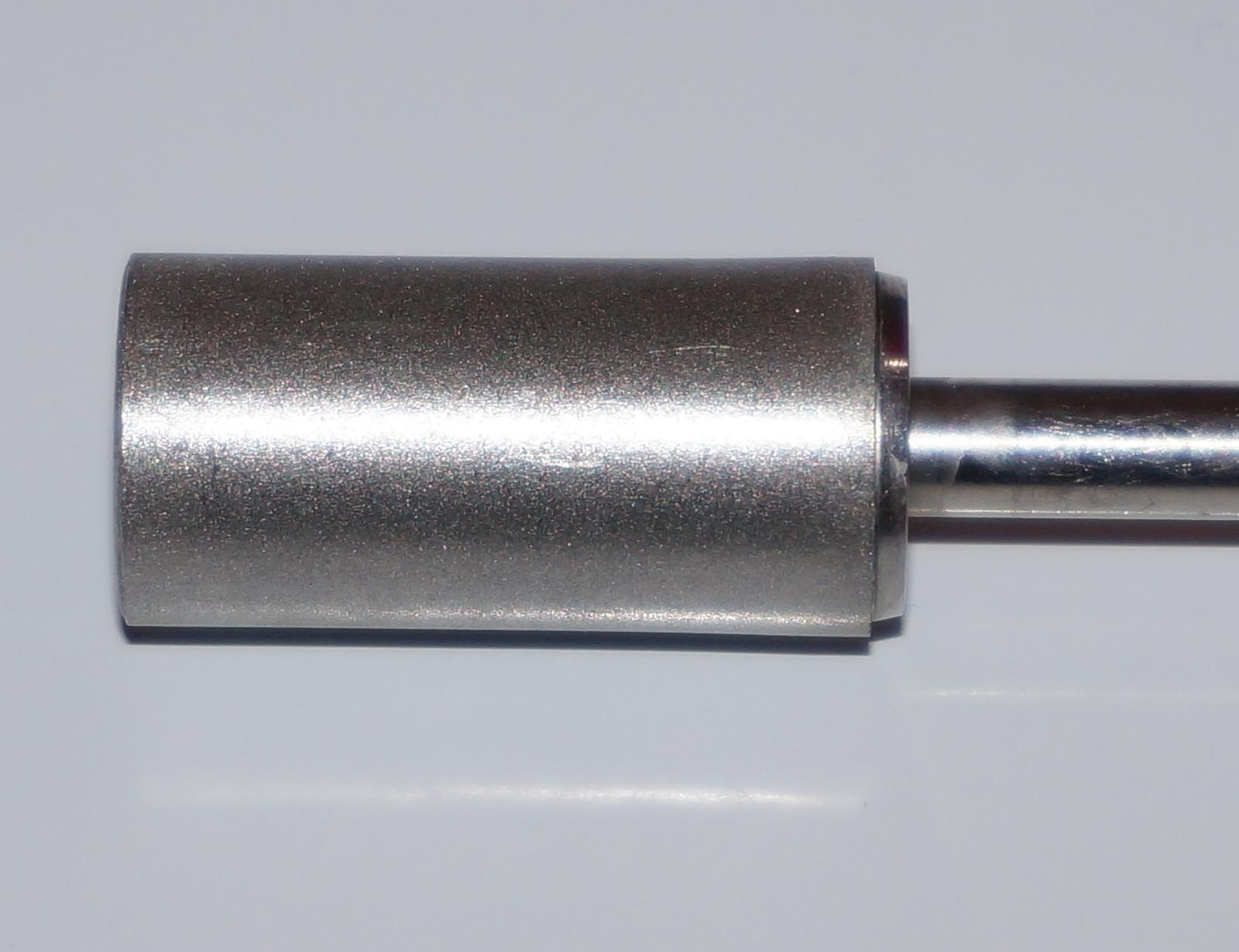

Basically it's just a plastic hook that I attach to a drill that allows me to agitate the heck out of the wort.

Basically it's just a plastic hook that I attach to a drill that allows me to agitate the heck out of the wort.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)