Hoppopotomus

Cedar Hollow Brewing

Thanks guys....I'll take all of your suggestions into consideration. What I'm still trying to figure out is if I even need a heating source in the Ale chamber. I have been fermenting ales in my upstairs laundry room since I started brewing, which is climate controlled, so I have never fermented in a sealed, insulated, small space like a chamber. Is there any feedback as to my question:

My Ale chamber is going to be under 6 cu. ft. once fully insulated and it will be air tight. The side of my basement that these chambers will be located in will be consistently in the upper 50's to low 60's, season dependent. With this small of a cubic volume in this type of ambient temperature......do I need a heat source? Also, is there a possibility that my Ale chamber could get too warm with heat generated during fermentation and I'll have to end up using the lager chamber? Just trying to figure a few things out. Thanks for your help!

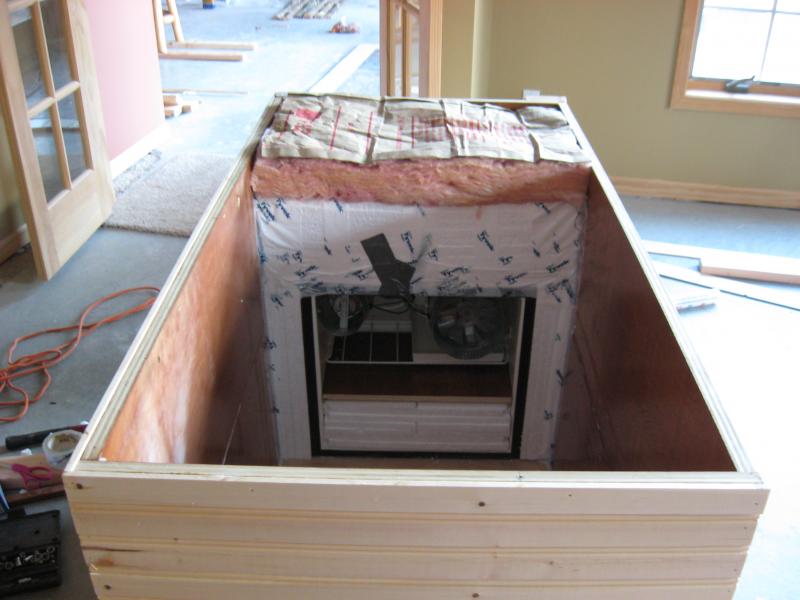

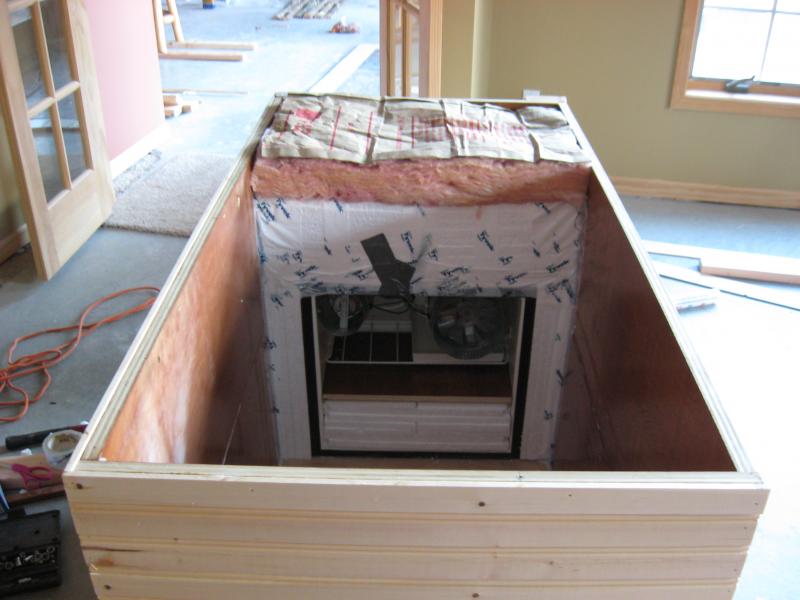

Oh.....here's a couple of pics of the lager chamber with most of the insulation in. The insulation for the bottom is actually under the sub-floor and is also 4.5" thick.

My Ale chamber is going to be under 6 cu. ft. once fully insulated and it will be air tight. The side of my basement that these chambers will be located in will be consistently in the upper 50's to low 60's, season dependent. With this small of a cubic volume in this type of ambient temperature......do I need a heat source? Also, is there a possibility that my Ale chamber could get too warm with heat generated during fermentation and I'll have to end up using the lager chamber? Just trying to figure a few things out. Thanks for your help!

Oh.....here's a couple of pics of the lager chamber with most of the insulation in. The insulation for the bottom is actually under the sub-floor and is also 4.5" thick.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)