Mongoose, I noticed your control panel, what kind is it or did you build it yourself? Also, what is the RO water to waste water ratio?

It's an Auber panel that I bought as a kit. Took me about six hours to build it, but while I did some electronics stuff many, many years ago, it's been....many, many years.

This is the current version:

https://www.auberins.com/index.php?main_page=product_info&cPath=64_66&products_id=809

Here it is complete, I believe:

https://www.auberins.com/index.php?main_page=product_info&cPath=64_65&products_id=794

BTW, if I were to build one of these again, I'd buy their wiring kit in a New York minute. I had to go several places to get the right wire, and it was a pain.

FWIW: One feature I feel is essential is a key that can be used to turn off the unit so a friend doesn't just decide to turn on an element to see how it works and burn it out.

Also, something that surprised me was that my unit has room to control two pumps with push-button switches. Given where I've had to mount this, I found that controlling pumps this way was....not as quickly accessible as I want.

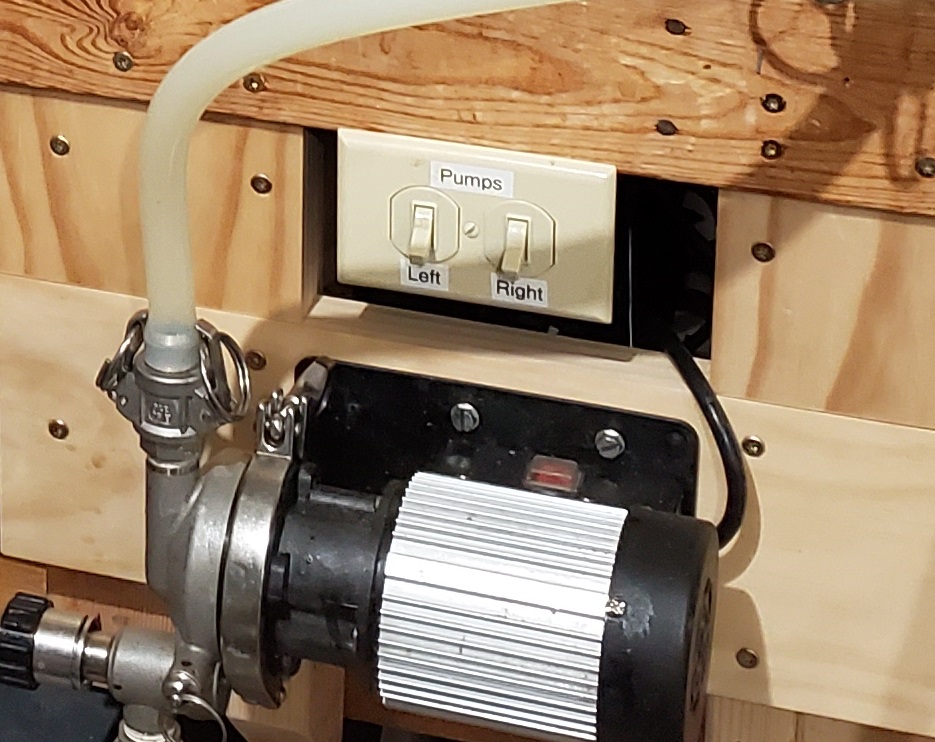

So I built a switch setup on the front of my bench that's very easy to hit when I want to control pumps quickly. I simply wired power to a couple outlets (can't see them, they're mounted under the bench top), then mounted a switch box to control them. I feed the power from a CFCI receptacle.

Having used it both ways, I like my switch setup far better. Even with using a Riptide, which has a switch on it, having easy-to-flip and easily-accessible switches is the way to go, for me, in my setup. YMMV.

Here's a couple pics showing those switches:

As far as the water rejection rate, I don't really know. I presume 4:1 but that's just a guess. It all goes right down the drain; I have that rejection line in a stand pipe under the sink.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)