- Joined

- Oct 6, 2017

- Messages

- 1,700

- Reaction score

- 982

I’ve been looking for something like this for ages

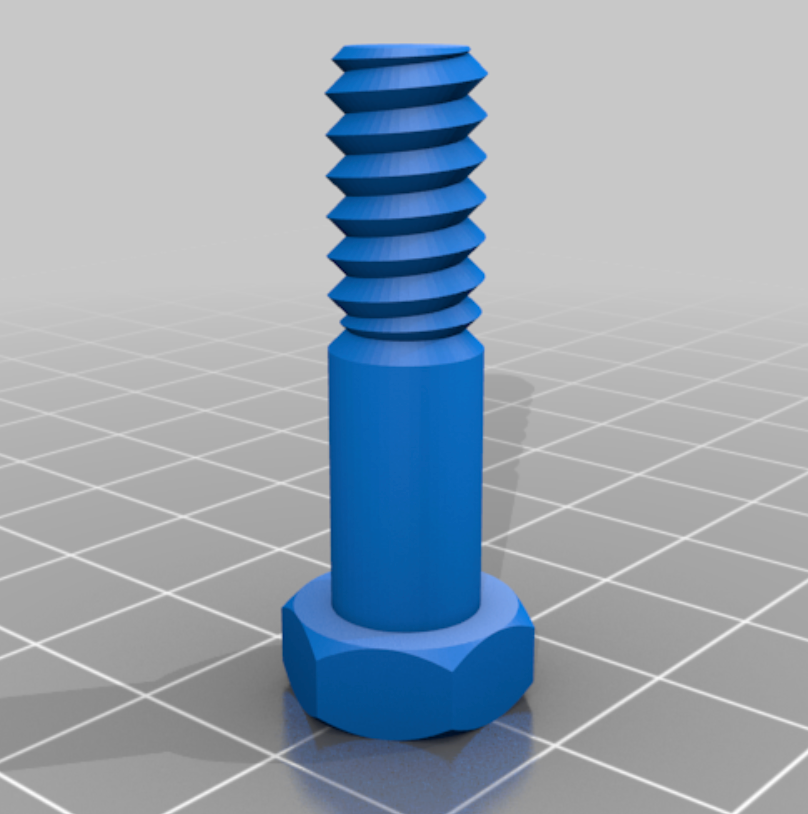

Can I suggest one modification that I think would make it easier to get the lids out without putting dirty fingers underneath the lids?

G slot at the rear opposite the front opening. This would allow you to place fingers on opposite sides of the lid to lift them out

Great suggestion--I've added models for this to Printables!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)