PacificNWBrewer

Well-Known Member

greenrhino said:That looks great. I'd like one too! One question though..... those holes look much too big for pellet hops and even too big for leaf, are yoiu going to add a screen to them to keep the hops out of the fermenter?

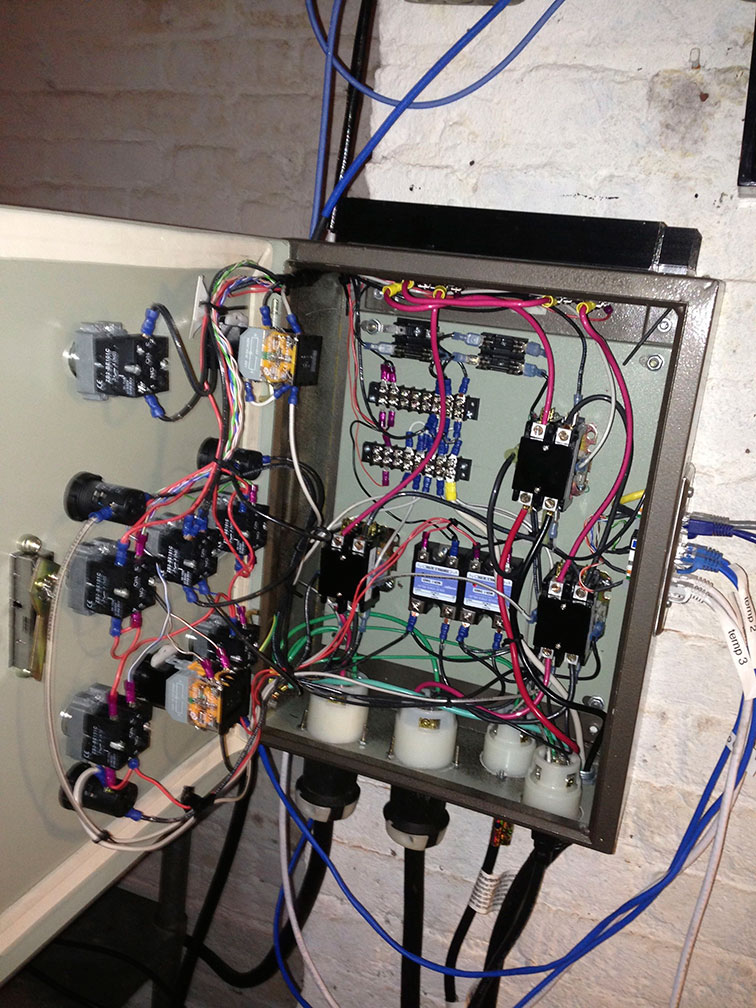

Odd question because that's not his false bottom, it's his control panel.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)