- Joined

- Aug 18, 2015

- Messages

- 35

- Reaction score

- 2

I might take this down with some 05 yeast at the end. Good points.

Don't know why you guys are having attenuation issues with Conan. I have used both Conan from a can of Heady Topper and GigaYeast. From my experience it attenuates way better than 05 or any of the standard clean yeasts including WLP090 (San Diego Super Yeast - the fastest and highest attenuating of the West Coast ale yeasts.) In fact the only two yeasts I have used that attenuate better than Conan are WLP099 (Super High Gravity Ale Yeast) and WLP045 (Scotch Whisky Yeast.)

Don't know why you guys are having attenuation issues with Conan. I have used both Conan from a can of Heady Topper and GigaYeast. From my experience it attenuates way better than 05 or any of the standard clean yeasts including WLP090 (San Diego Super Yeast - the fastest and highest attenuating of the West Coast ale yeasts.) In fact the only two yeasts I have used that attenuate better than Conan are WLP099 (Super High Gravity Ale Yeast) and WLP045 (Scotch Whisky Yeast.)

Probably b/c you're a super awesome Brewer

If this Yeast does not start soon I will pitch this in.

When did you pitch? I've had plenty of beers not show active air locks until 36 or more hours.

clearly, please let us know what that something is. conan has now twice crapped out on me early. i have no trouble getting other yeasts to attenuate as expected. since other folks have experienced the same, i suspect that it's the yeast and not just meDon't know why you guys are having attenuation issues with Conan.

I must be doing something right.

i think it's a good idea, because an under-attenuated (sweet) IPA is gross. US-05 seems like a fine choice since it attenuates well... certainly more reliable that Conan, in my experience. given that almost no yeast growth will happen, the second yeast will add little to no flavor. that's why i wasn't worried about adding saison yeast to my stuck Conan DIPA - i just need attenuation.Do you think it's a good idea to finish this clone with US-05? If so, why? Also, do you have any experiments comparing Conan attenuation to US-05? Maybe you can run an experiment.

Maybe Conan is unreliable and I got lucky both times and got great strains, or maybe Conan isn't so great at lower pitching rates. From my experiment Conan attenuates better than WLP090 (which attenuates better than US-05 from my experience) when pitching at 1.0.

Or maybe people just aren't pitching enough yeast. I always make a starter AND I always know how many cells I am actually pitching. I would advise people not to rely on how many cells the manufacturer says are in the product nor to just make a starter and assume they have enough. Make a starter, cold crash it, and make sure you have 25 ml of solid yeast for every 100 billion cells you need.

Until anyone can provide a controlled experiment showing US-05 attenuates better than Conan, I would suggest using WLP099 if your Conan craps out.

:

:I've always had WLP099 finish at about 72%

clearly, please let us know what that something is. conan has now twice crapped out on me early. i have no trouble getting other yeasts to attenuate as expected. since other folks have experienced the same, i suspect that it's the yeast and not just me

i think it's a good idea, because an under-attenuated (sweet) IPA is gross. US-05 seems like a fine choice since it attenuates well... certainly more reliable that Conan, in my experience. given that almost no yeast growth will happen, the second yeast will add little to no flavor. that's why i wasn't worried about adding saison yeast to my stuck Conan DIPA - i just need attenuation.

i would not pitch the US-05 directly into the partially fermented beer. instead i would rehydrate, pitch into a hopped starter whose gravity and IBUs are similar to that of the stuck beer, and then pitch once it's fully active and has had a chance to get used to the presence of alcohol.

yup, i ramp almost all my beers to some extent.do you ramp up temperatures at the end of fermentation? I did three or 5 days kind of cool (63) and then pumped it up past 75 over the next few days. zero problems with attentuation

no you don't.I need to stop brewing IPAs

yup, i ramp almost all my beers to some extent.

on this last conan batch, i pitched at 64, kept it there for 3 days, then slowly ramped to 72.

So I'm interested in getting a conan strain prob the giga yeast so if I ferment in my basement which is 64 ambient then after 3 days move the carboy upstairs where it's 70 deg help attenuation? I've done it before with wlp500 hefe strain and on all my RIS's using 002 and 007 and so far it's worked. Also did the same with a dipa using 2nd gen 001 and it got down to 1.008 using sugar in the boil though of course. I also hear Conan attenuated better after continuing generations.

yup, i ramp almost all my beers to some extent.

on this last conan batch, i pitched at 64, kept it there for 3 days, then slowly ramped to 72.

all is good now: my re-pitch of saison yeast got me down to 1.011

no you don't.

I pitched more than enough this time around and did 72 for three days, 80 for one, and then 65 for a week.

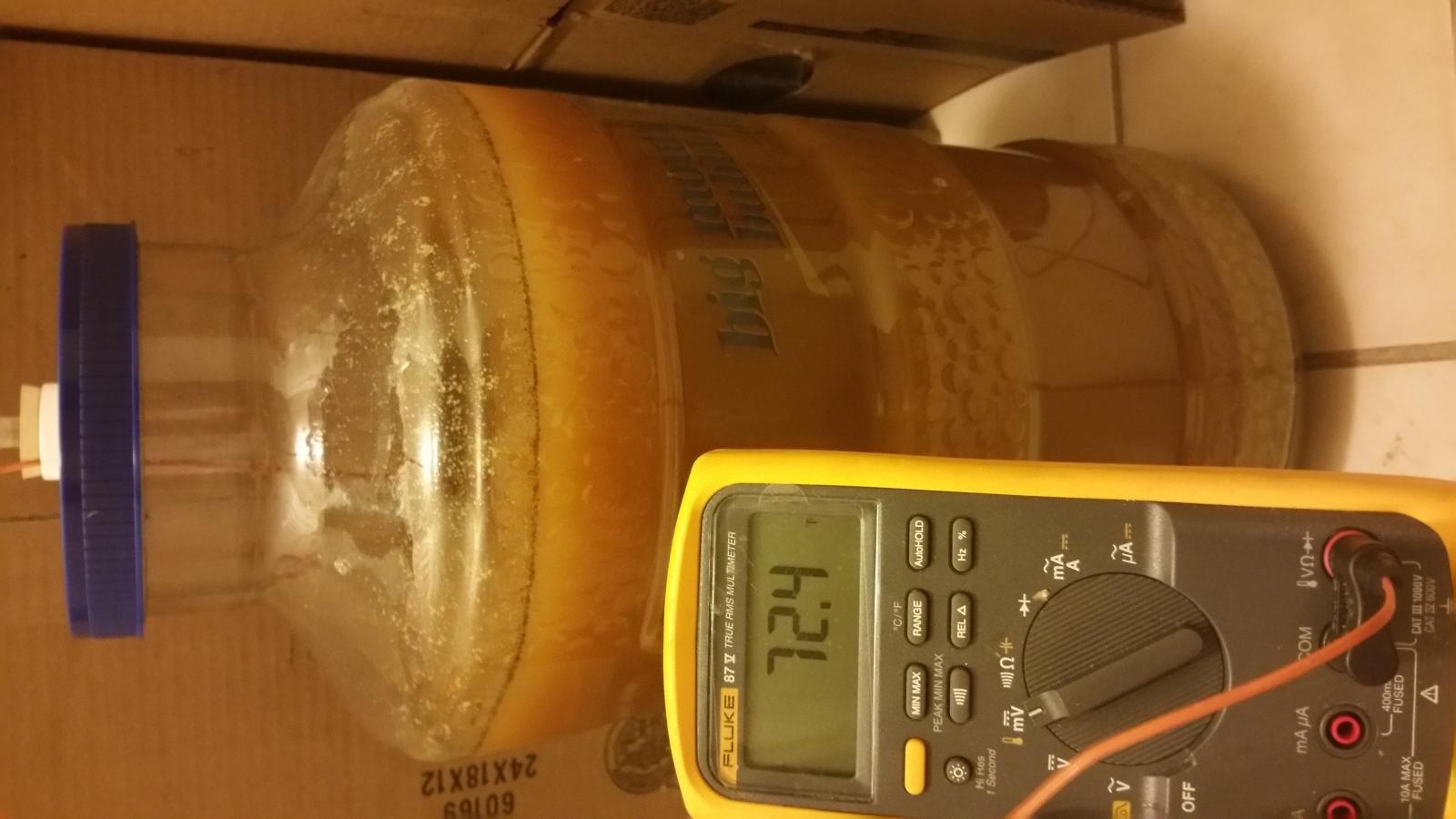

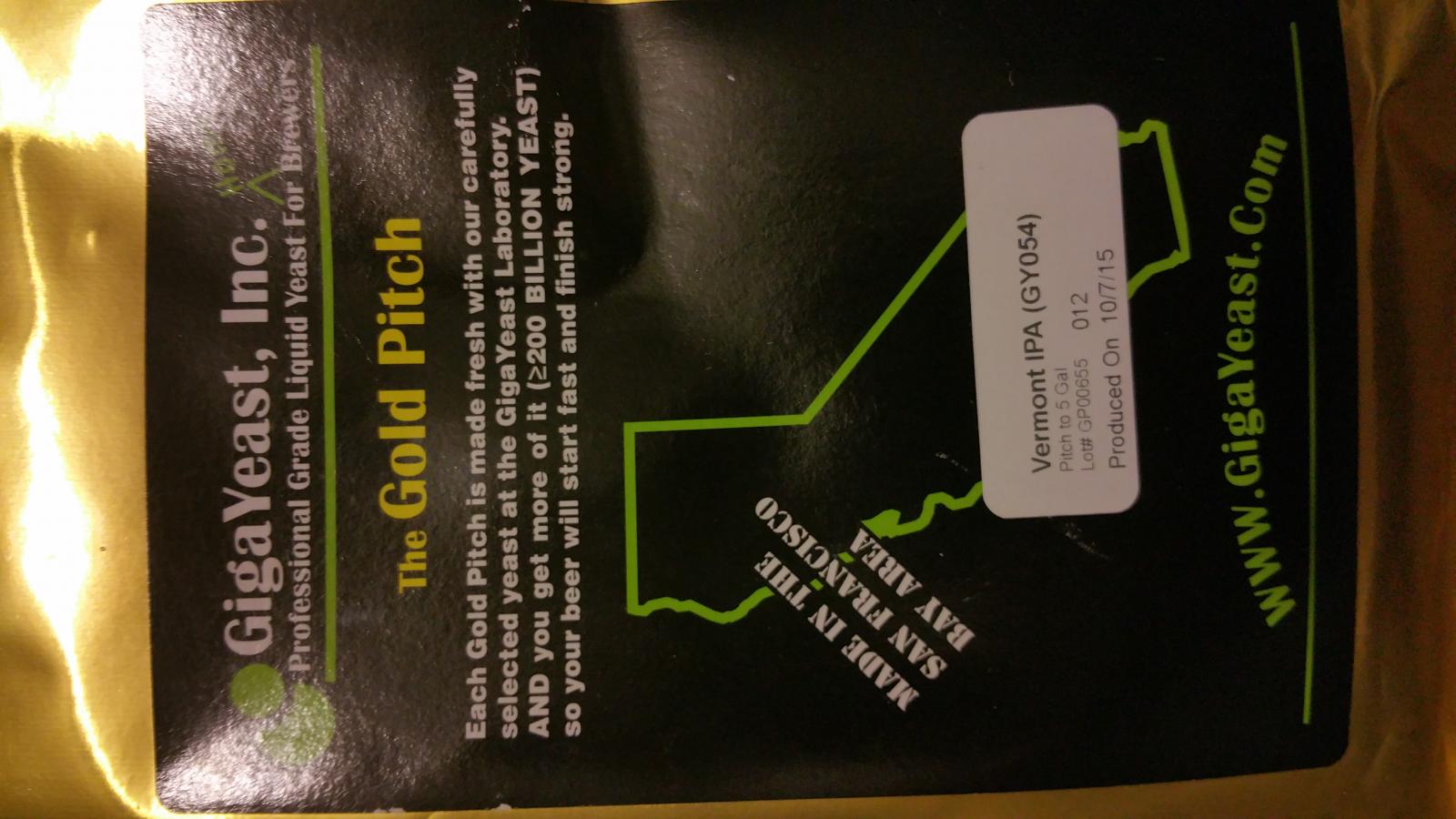

I think my Heady clone has a stuck fermentation. Ugh. I did a 1L starter with the Gigayeast version of Conan. Looks like it petered out around 1.014. Should have down a 2L starter. I was hoping to dry it out down to 1.010 or a little lower. I fermented for 1 week at about 64F and then ramped it up to 72F where it's been for 5 days. I took the gravity reading after 1 week and it was at 1.014 and it's still there now even after ramping up the temp.

I tasted the sample yesterday and it was OK. I can never get a good sense from tasting a sample during fermentation whether or not it will be good once it is dry hopped and carbed.

Should I:

a) Roust up the yeast with a sanitized spoon and see if that can get me down a few more points

b) Roust up the yeast and add some Nutriferm or something to restart fermentation

c) Add more Conan

d) Add some other yeast

e) Ramp up the temp beyond 72F

I'm planning to do the 1st dry hop in the keg at room temp while on gas so I don't know how much more it will ferment. Should I do the 1st dry hop in the primary instead?

I would. I double dry hop all my IPA's. first dose in primary around day 5-7. Then second dose in a dry hopping keg for a couple days before jumping to serving keg. I like the initial dry hop in the primary as it is finishing up.