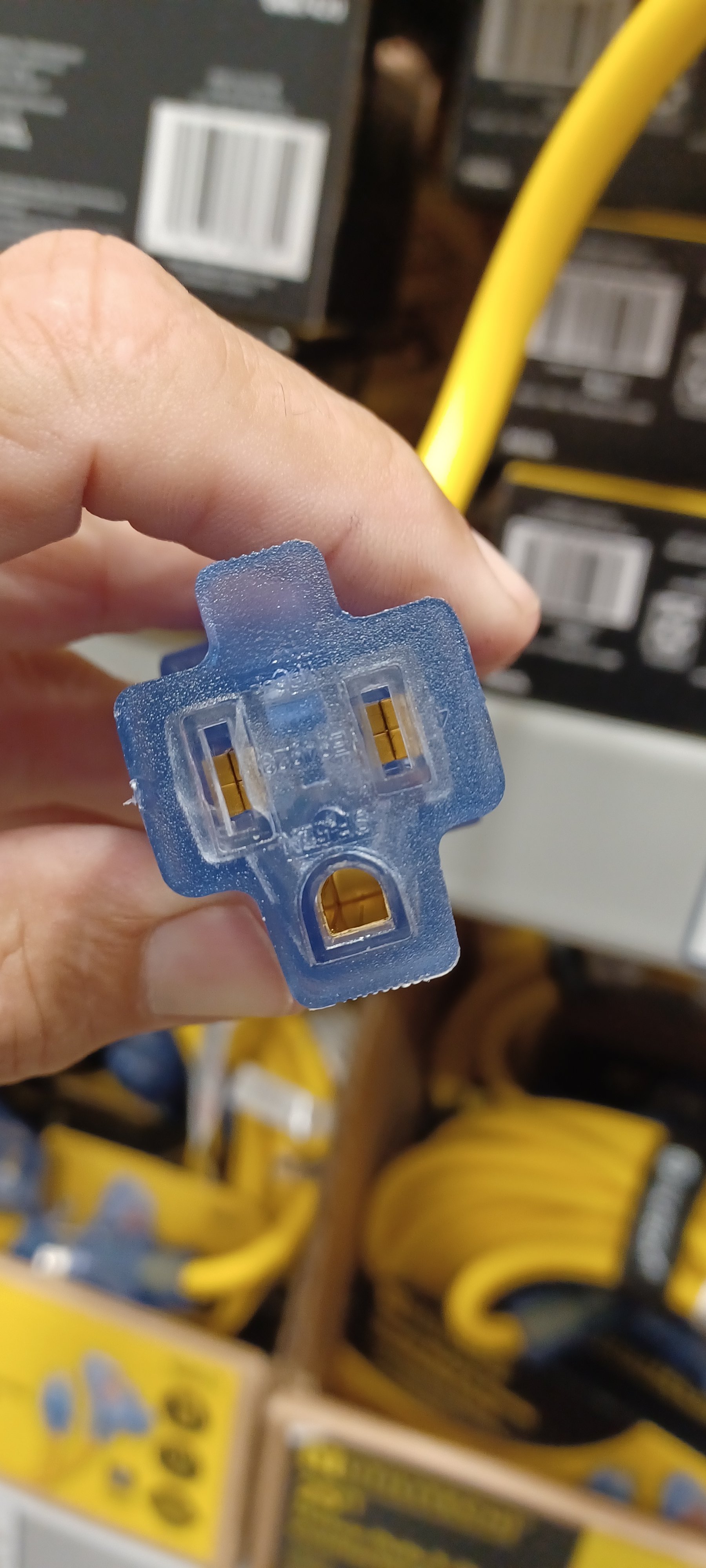

I've had various heating elements in the past actually fuse plugs together. I use heavy gauge extension cords but I have experienced where a 1500 watt heater would fuse with the ext cord after extended use.

For example, I have a 1500 watt immersion heater (not for brewing) that has permanently fused to an extension cord. The heater is 16AWG (yeah, kinda small) and the ext cord is 12AWG 10 foot. I didn't have any grease applied.

Another time it was on my kettle. 1500 watt element with 10 gauge pigtail and 12 AWG ext cord and it fused after running a couple hours. again, no grease.

I'm using dielectric grease now but have just read that it is not conductive??? So it's not helping to lower the resistance (which was probably the cause of the heat and fusing).

Is there a better or "conductive" grease to use to help reduce any resistance at the plug connections to help prevent excessive heat and fusing?

For example, I have a 1500 watt immersion heater (not for brewing) that has permanently fused to an extension cord. The heater is 16AWG (yeah, kinda small) and the ext cord is 12AWG 10 foot. I didn't have any grease applied.

Another time it was on my kettle. 1500 watt element with 10 gauge pigtail and 12 AWG ext cord and it fused after running a couple hours. again, no grease.

I'm using dielectric grease now but have just read that it is not conductive??? So it's not helping to lower the resistance (which was probably the cause of the heat and fusing).

Is there a better or "conductive" grease to use to help reduce any resistance at the plug connections to help prevent excessive heat and fusing?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)