Diamonddave74

Active Member

- Joined

- Mar 27, 2016

- Messages

- 38

- Reaction score

- 10

David Heath is a great ambassador for the grainfather. Lots of good nuggets

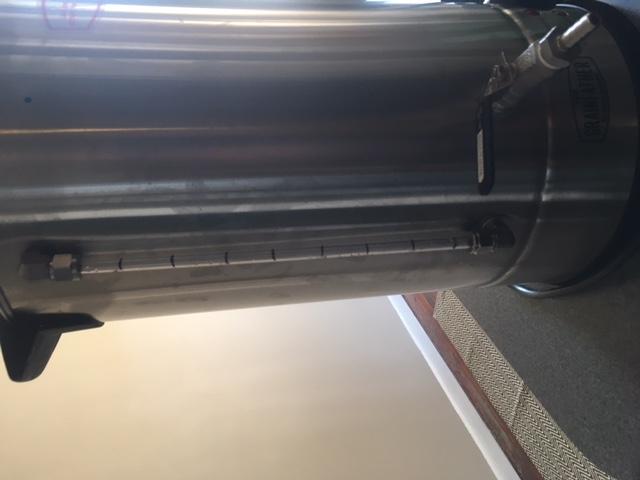

Thinking about doing this to the main unit, got it real pretty on the HLT.

I have been planning on doing this for a while, except with a needle valve, but have been waiting for my warranty to expire first, which should be soon. what size is you valve there?

I have been planning on doing this for a while, except with a needle valve, but have been waiting for my warranty to expire first, which should be soon. what size is you valve there?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Food for thought: I use a piece of 1/2" silicone tubing and a butterfly clamp to hold tubing on to the GF sparge tank spigot. The 1/2" valve is on the end of the hose...haven't used it yet and if it doesn't work efficiently, I can try the valve on the tank and reverse it. I'll post a pic later when I can dig out my stuff.

I have tried that the past few times brewing. No matter how tight you put the clamp, because of the conical shape of the grainfather spigot, it slips off all the time. I'm just going to do what the others have done and throw a 1/2 valve onto the body of the GF Sparge body and call it a day.

I have tried that the past few times brewing. No matter how tight you put the clamp, because of the conical shape of the grainfather spigot, it slips off all the time. I'm just going to do what the others have done and throw a 1/2 valve onto the body of the GF Sparge body and call it a day.

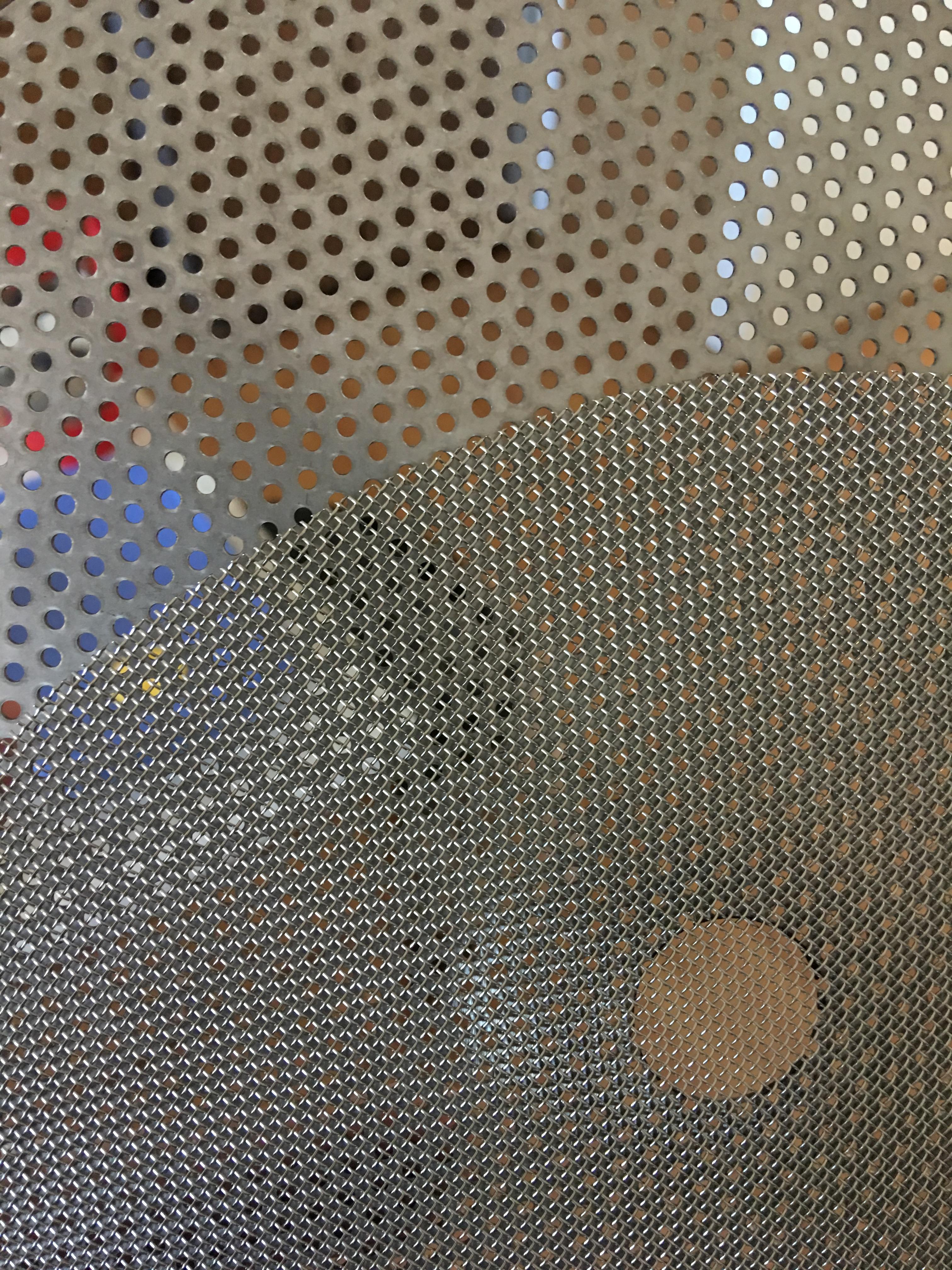

I'm totally putting a mesh bottom on! But one question, the #20 Mesh (1mm gap for the metric folk) seems to be the default.

Is there any reason not to go down to the next size at #30 and get a gap size nearly half as large? I feel like the wort shouldn't be restricted any more, and you could reduce grains and grain bits to literally zero with that size. Thoughts?

Ok just got the ebay mesh screen that showed up in the mail today. Im impressed. Very fine holes and this sucker has some weight to it. Should remain functional for quite some time. Excited to give this a try next batch.

Hi. I used the tips of my kitchen shears and it worked fine. Just go slow and take a little at a time. Edif you dont mind my asking, what did you use to cut the inner circle out? I was thinking a jewelry cutter, but dont know if the mesh is too hard.

if you dont mind my asking, what did you use to cut the inner circle out? I was thinking a jewelry cutter, but dont know if the mesh is too hard.

What kind of gap do you guys use on your 3-roller mills? I have a monster mill mm3 and a gap of 0.055" and get insanely slow sparge time(2 hours +). I have read about crush grades to 0.9mm, but that is a rater fine crush?

Have either of you seen the Grainfather Videos by David Heath? They're very good and contain a couple tips & tricks vid's as well as several brew day vids. I found they are almost essential to get the most out of using the Grainfather.

Try conditioning your malt with 1-2% by weight water. It should leave more of the husk in tact, thus creating a more free flowing sparge.

http://braukaiser.com/wiki/index.php?title=Malt_Conditioning

Ill give it a go! I`m a bit curious about the crush I have used since I see a lot of recommendations a lot lower than 0.055". I feel that the crush I have used is a bit to fine.

Well, I went ahead and purchased a GF connect from Midwestsupplies using a 20% off coupon. I am coming from an extract brewer (started last summer), and this is my first step into all grain. It should be here next week, so I'll go ahead and put it through it's paces that weekend.

I have read through the entire thread over the last few days. Interesting personalities in here for sure...

Ill give it a go! I`m a bit curious about the crush I have used since I see a lot of recommendations a lot lower than 0.055". I feel that the crush I have used is a bit to fine.

Shipping was also pretty fast... it arrived today bright and early. It was well packed and upon initial inspection, all items seem to be in order and accounted for. I went ahead and plugged in the controller and it immediately paired with my phone. I changed a few settings (240>120v, c>f, US units, etc) all very quickly. I unplugged it and replugged it, all settings remained. I took a few pictures, but it's nothing you all haven't seen already. I'll do a test boil this weekend and make sure everything is clean and in working order, and likely do my first all grain brew next weekend. I'm looking forward to it.