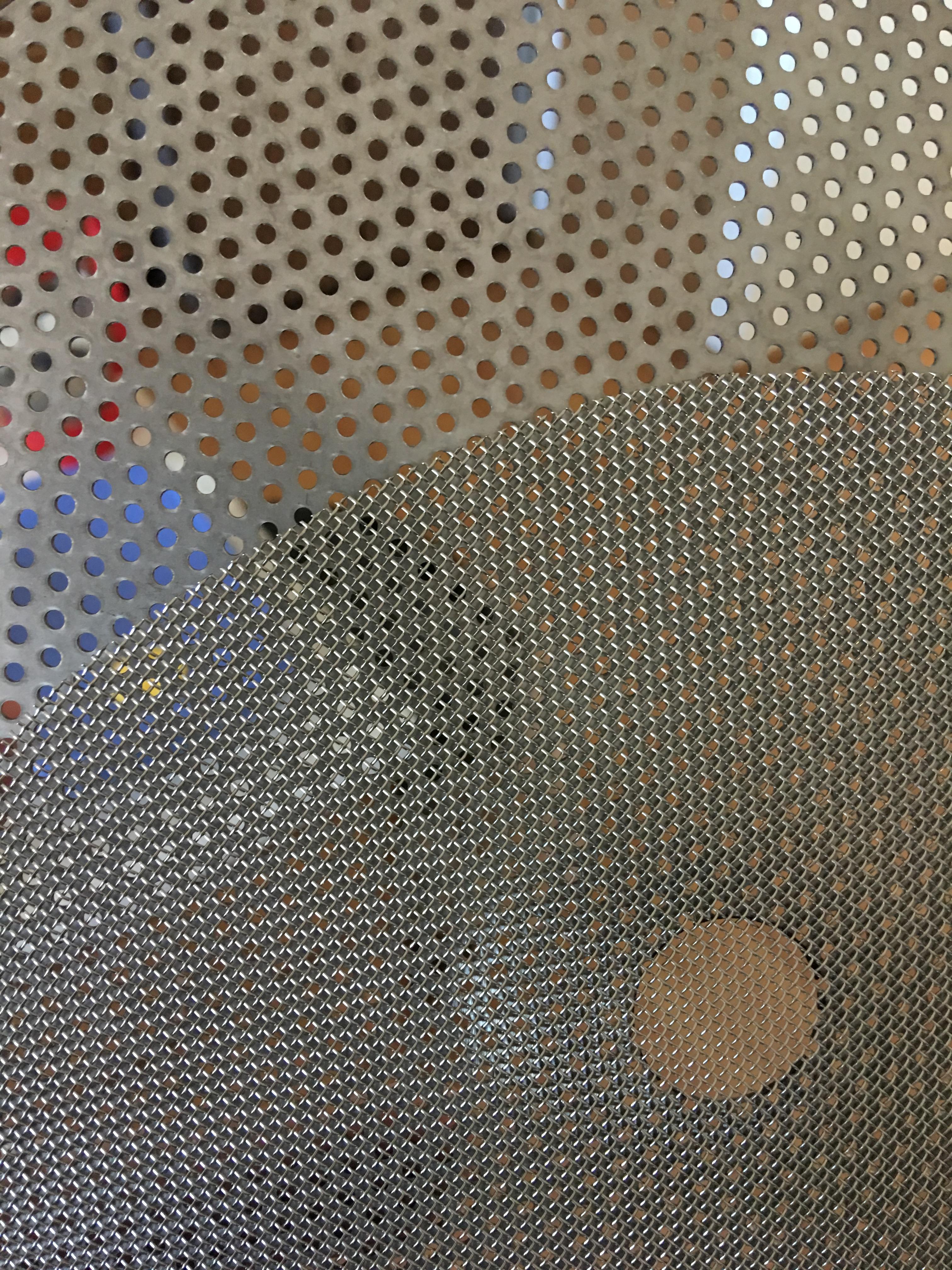

Just finished my 2nd brew in the Grainfather. I am new to all grain brewing and I have learned a lot in the first 2 batches. This brew was a hoppy Belgian triple with 12# of Weyerman Pilsner 6oz hops and finished with 2# corn sugar. After reaching mash temp I got all the grains in and stirred up real good. Once I started the pump,it did not seem like I was gaining much flow through the grain. I took the top screen off and gave it another good stir, especially on the bottom. This definitely helped, I could run the ump at nearly full flow from the beginning. Sparging went well with a good consistent flow until the after I had all the water in and was waiting for it to run through the grain. It seemed to be draining incredibly slow. There was no water on the top screen anymore so I removed it and stir a little to get the last water through the bottom screen. By the time it slowed my wort was already over 200 degrees. Did the steam make it slow? Started the boil with a 1.064 on about 6 gallons. Boiled for 15 minutes and then the wife called that she needed picked up! I was about to tell her she needs to wait 45 minutes, but I thought better of it! Shut it down and restarted after I got home. Added the corn sugar and the OG came in at 1.080 on 5.25 gallons(Added about half gallon of water to get there). Added 2 packs of T-58 yeast and it was bubbling within hours. Drying out some of the spent grains now! Only other concern was that the GrainFather had a 2 inch circle of scorched residue on the bottom. I hope that it has no impact on the flavor. The color in the test tube looked good. The wort was very sweet with no taste of scorch to it, but it was very sweet. Oh well, If it does have a little flavor from the scorch, I guess I just created a Smoked Hoppy Belgian Triple!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)