I'm trying to make a push to finish everything up but it's slow going at the end. Tonight I got the diptubes and herms coil installed in the kettles, also ran some water through my chiller to leak test, and good news, no leaks. However, I'm having a really hard time getting the fill valves that are installed on my water supply to seal. If I can't get them to seal I may just say the heck with it and let them leak, they won't have water turned onto them all the time anyway and they aren't used for a very long period of time.

Also, word to the wise, I had a 30A 220 outlet installed in my house and the plug on the hosehead is a 50A plug, long story short I ended up replacing my 30A receptacle with a 50A to allow me to plug in the hosehead, it's still a 30A breaker with wire only capable of 30A so it will still trip all the same if I overcurrent the circuit, however, the receptacle allows me to actually plug in the hosehead.

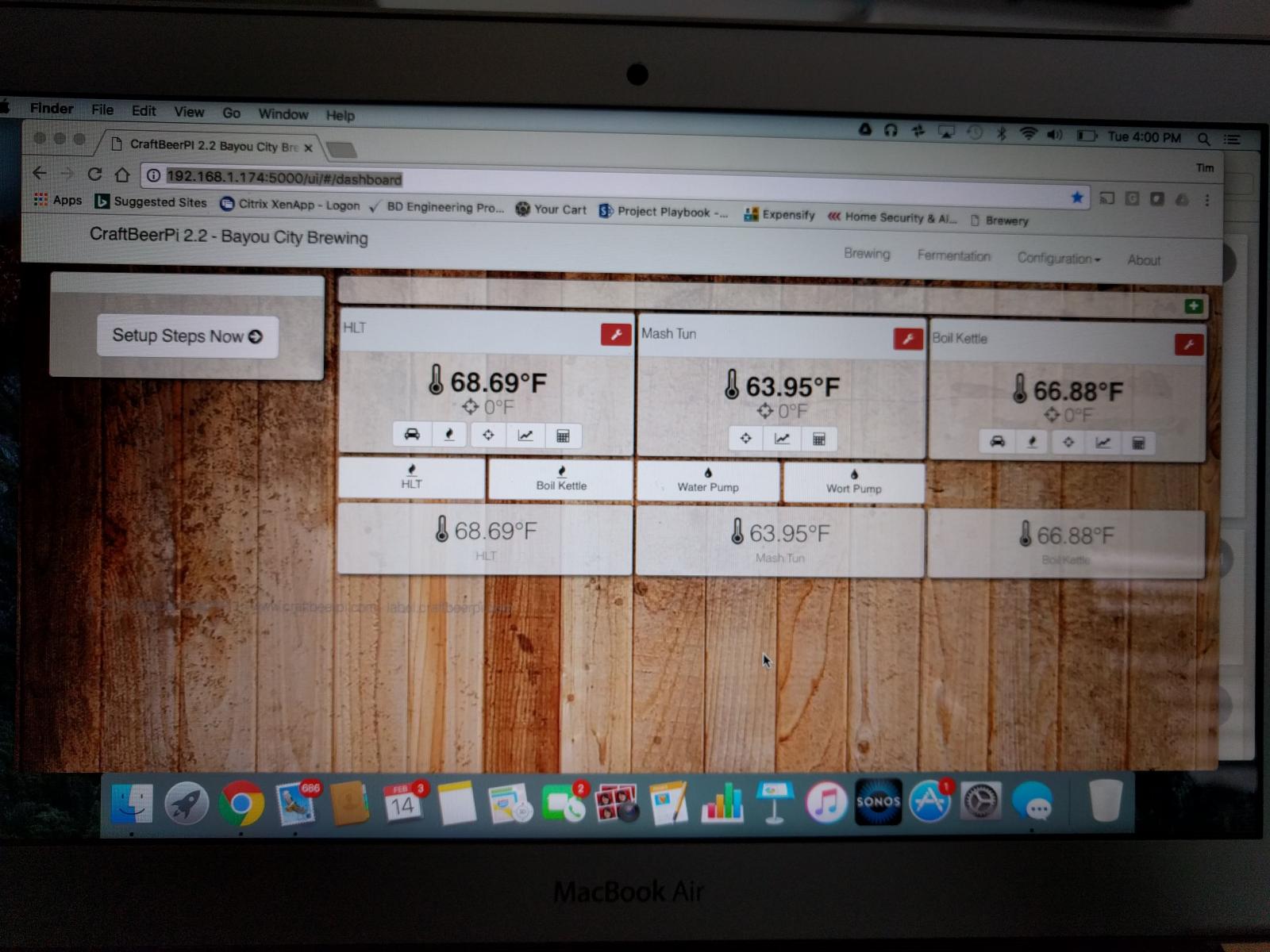

Tomorrow I hope to get the hosehead booted up, connected to the network and controlling my elements and pumps. Once that's working I can finally properly leak test everything and get it ready to brew. I was hoping to brew Saturday on it, but doesn't look like that's going to happen.

Also, word to the wise, I had a 30A 220 outlet installed in my house and the plug on the hosehead is a 50A plug, long story short I ended up replacing my 30A receptacle with a 50A to allow me to plug in the hosehead, it's still a 30A breaker with wire only capable of 30A so it will still trip all the same if I overcurrent the circuit, however, the receptacle allows me to actually plug in the hosehead.

Tomorrow I hope to get the hosehead booted up, connected to the network and controlling my elements and pumps. Once that's working I can finally properly leak test everything and get it ready to brew. I was hoping to brew Saturday on it, but doesn't look like that's going to happen.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)