r8rphan

Well-Known Member

Going to be brewing for the first time with my new upgraded system this weekend, and have a few questions about the process...

Old system: propane heated keggle, with rectangular coleman cooler mash tun.. two 6.5g glass carboy fermenters... no pump/recirc... well water (no water test, but evidence of low PH)

New system: Single electric eBIAB keggle, 5500w heater element, single Speidel 60L fermenter, pump/recirc, RO filtered well water... (4ppm measured in initial test of filter system)

I have things plumbed so that I can use recirculation, but am planning on not doing it that way for my first couple brews.. Just straightforward BIAB...

It's been three years since I brewed, so I'm a bit rusty, and there are several process changes in the new system...

All my old recipes were based on 80% efficiency, double batch sparge, mostly IPAs, some PAs... Typically 22-25lbs of grain...

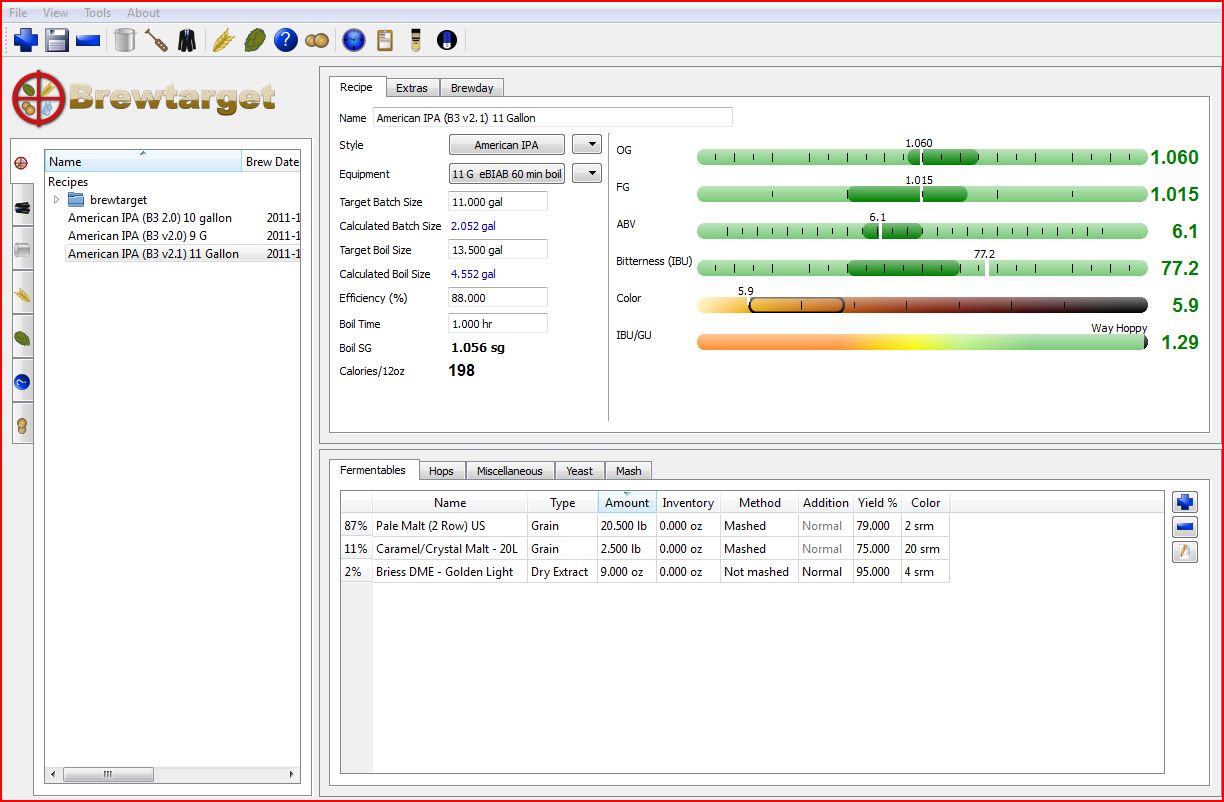

Gonna start with a basic American IPA based on B3's beer kits... The recipe is for 10g, but I might start with a 9g version until I have an idea of system volumes, etc.

10g AIPA Recipe

21# of 2 row

2.5# 20L Crystal

4.25oz magnum pellets (60 min)

4.25oz cascade pellets (10 min)

4.25oz cascade pellets (1 min)

1 oz cascade leaf (dry hop)

2 packets of Safele S-05 dry yeast

Water Volumes

If I have calculated all things right, there will be 4g of water below the false bottom, and I will need an additional 7.35g for a mash consistency of 1.25qt per pound.. This means a total of 11.35g strike water, which when grain is added (at .32qt per pound), should bring the total volume to 1.9g additional space or 13.25g...

When I remove the grains, I should lose 2.9g of water volume, so I will need to have 4g of modified RO water ready to make up and bring to 12.5g pre boil volume.. I understand that when I squeeze the grains, I will get some of that water back, but plan to have 5-6 gallons ready just in case... Figuring .5-1 gallon of losses, and 60 mins boil time, I should have 10-10.5g of beer at the end of ferment...

Somebody please check my math

Water Additions

So now, I'll be starting with RO water and must add stuff to it to bring it to the proper base water for IPAs...

I bought a pound of calcium chloride pellets, a pound of Calcium Carbonate powder, and 2.5 pounds of acidulate grain..

In reading other threads on water, I came across this post by @ajdelange

Questions Based On The Above Info And Quote

*) Is gypsum, chalk, and Calcium Carbonate all the same thing? Is he talking about adding it to the finished beer? Or should I be adding it to the grains or pre-mash water? If so, how much and when/where?

*) When do I add the Calcium chloride pellets, and do they need time to dissolve? Do I add them to the water before I add the grains? Do I put them in the keggle before I start filling it from the RO filter? Do I just add them to the grains?

*) Do I proportion the calcium chloride between the total volume of strike water and then a proportioned amount in the makeup water I will be setting aside, or do I put it all in the keggle with the initial strike water and just add the RO water after the mash directly from the filter?

*) Does the Sauermalz add any 'sugar' to the recipe that I need to adjust for? I'm assuming I will probably have to recalculate the mash water volumes to account for this additional 1/2# of grain, right? But do I also need to reduce the 2 Row base malts to account for sugars in the Sauermalz?

*) Also, the Sauermalz is just added to the grain bill and crushed with it, right? Or do I add it separately in the mash water and then remove it before adding the mash grains?

After I get through this first mash, I can measure the pre-boil OG and adjust the make up water, boil time, hops additions, etc. to match it.. I should have a better idea of mash efficiency, etc. after this first one....

So mostly, my questions are about water additions, what, when, how, etc... I'm planning on doing a 1 hour mash, measuring gravity every fifteen minutes, stirring lots, and adjusting on the fly... might even add a little mash water if there's room enough...

Once I have all of this information settled, I guess I'm ready to take the new system for a test drive....

Old system: propane heated keggle, with rectangular coleman cooler mash tun.. two 6.5g glass carboy fermenters... no pump/recirc... well water (no water test, but evidence of low PH)

New system: Single electric eBIAB keggle, 5500w heater element, single Speidel 60L fermenter, pump/recirc, RO filtered well water... (4ppm measured in initial test of filter system)

I have things plumbed so that I can use recirculation, but am planning on not doing it that way for my first couple brews.. Just straightforward BIAB...

It's been three years since I brewed, so I'm a bit rusty, and there are several process changes in the new system...

All my old recipes were based on 80% efficiency, double batch sparge, mostly IPAs, some PAs... Typically 22-25lbs of grain...

Gonna start with a basic American IPA based on B3's beer kits... The recipe is for 10g, but I might start with a 9g version until I have an idea of system volumes, etc.

10g AIPA Recipe

21# of 2 row

2.5# 20L Crystal

4.25oz magnum pellets (60 min)

4.25oz cascade pellets (10 min)

4.25oz cascade pellets (1 min)

1 oz cascade leaf (dry hop)

2 packets of Safele S-05 dry yeast

Water Volumes

If I have calculated all things right, there will be 4g of water below the false bottom, and I will need an additional 7.35g for a mash consistency of 1.25qt per pound.. This means a total of 11.35g strike water, which when grain is added (at .32qt per pound), should bring the total volume to 1.9g additional space or 13.25g...

When I remove the grains, I should lose 2.9g of water volume, so I will need to have 4g of modified RO water ready to make up and bring to 12.5g pre boil volume.. I understand that when I squeeze the grains, I will get some of that water back, but plan to have 5-6 gallons ready just in case... Figuring .5-1 gallon of losses, and 60 mins boil time, I should have 10-10.5g of beer at the end of ferment...

Somebody please check my math

Water Additions

So now, I'll be starting with RO water and must add stuff to it to bring it to the proper base water for IPAs...

I bought a pound of calcium chloride pellets, a pound of Calcium Carbonate powder, and 2.5 pounds of acidulate grain..

In reading other threads on water, I came across this post by @ajdelange

The recommendation is always the same. Add 1/2 tsp of calcium chloride to each 5 gallons of RO water you use to brew - mash and sparge and add sauermalz in the amount of 2% of the other grains by weight. You almost guaranteed a decent beer if you do these things. Brewing water treatment is really pretty simple.

If you are brewing ales you will probably want to experiment with adding sulfate. Put some of your beer in a glass and taste it critically. Now add minute amounts of gypsum (make a solution and add a drop or 2) and then taste again. If you think the beer tastes better with the sulfate add more and taste again. Keep doing this until the taste stops improving. Scale the addition that gives you the best tasting beer to the full brew length and add that much gypsum to the brew the next time you do the beer. Critically taste that beer and as you brew it subsequent times keep adjusting until you achieve Nirvana. Depending on the style of beer you may find this at anywhere from 0 (lagers brewed with noble hops) to 400 mg/L (some ales). You should also experiment with chloride levels.

Questions Based On The Above Info And Quote

*) Is gypsum, chalk, and Calcium Carbonate all the same thing? Is he talking about adding it to the finished beer? Or should I be adding it to the grains or pre-mash water? If so, how much and when/where?

*) When do I add the Calcium chloride pellets, and do they need time to dissolve? Do I add them to the water before I add the grains? Do I put them in the keggle before I start filling it from the RO filter? Do I just add them to the grains?

*) Do I proportion the calcium chloride between the total volume of strike water and then a proportioned amount in the makeup water I will be setting aside, or do I put it all in the keggle with the initial strike water and just add the RO water after the mash directly from the filter?

*) Does the Sauermalz add any 'sugar' to the recipe that I need to adjust for? I'm assuming I will probably have to recalculate the mash water volumes to account for this additional 1/2# of grain, right? But do I also need to reduce the 2 Row base malts to account for sugars in the Sauermalz?

*) Also, the Sauermalz is just added to the grain bill and crushed with it, right? Or do I add it separately in the mash water and then remove it before adding the mash grains?

After I get through this first mash, I can measure the pre-boil OG and adjust the make up water, boil time, hops additions, etc. to match it.. I should have a better idea of mash efficiency, etc. after this first one....

So mostly, my questions are about water additions, what, when, how, etc... I'm planning on doing a 1 hour mash, measuring gravity every fifteen minutes, stirring lots, and adjusting on the fly... might even add a little mash water if there's room enough...

Once I have all of this information settled, I guess I'm ready to take the new system for a test drive....