Okay, so Saturday I just kinda 'winged it'...

Friday night I tried preparing the water.. Since my pressure pump for the house puts out lower pressure than the old one, and the water is barely above freezing this time of year, I bought a cheap chinese diaphragm pump for less than 20 bucks off of ebay, with the plan being to fill a bucket with hot water (135 degrees), and then hook it to the pump and let the pump pressurize the RO filter to increase output... The plan was to do this in the house and collect enough water to pour into the keggle in the morning...

Worked like a champ for about an hour or so and then burned up...

So, I called it quits for the night and thought about what I should do... It dawned on me, that if I were to crack the kitchen sink hot water so that just barely enough water flowed to keep the tankless heater heating the water, I could put the RO filter out on the porch with the brewery, and feed hot water to it out there on the porch directly into the keggle without buckets or anything else...

So the next morning I tried it and it worked like a charm...

Anyways, on to brewing... So I crushed the grains, and started the mash.. I needed just over 11 gallons for the mash in, so I added 1 TBS of Calcium Chloride, and searched through the posts on this thread and found that Bobby M said he uses 2.5 milligrams per five gallons of lactic acid... So I added 1 TSP of lactic acid to the water and started heating for the mash...

After I removed and squeezed the grains, I poured rinse water over them and squeezed them again to get the needed amount of make up water for the boil... But I forgot (too late) to treat the rinse water... It was pure RO water...

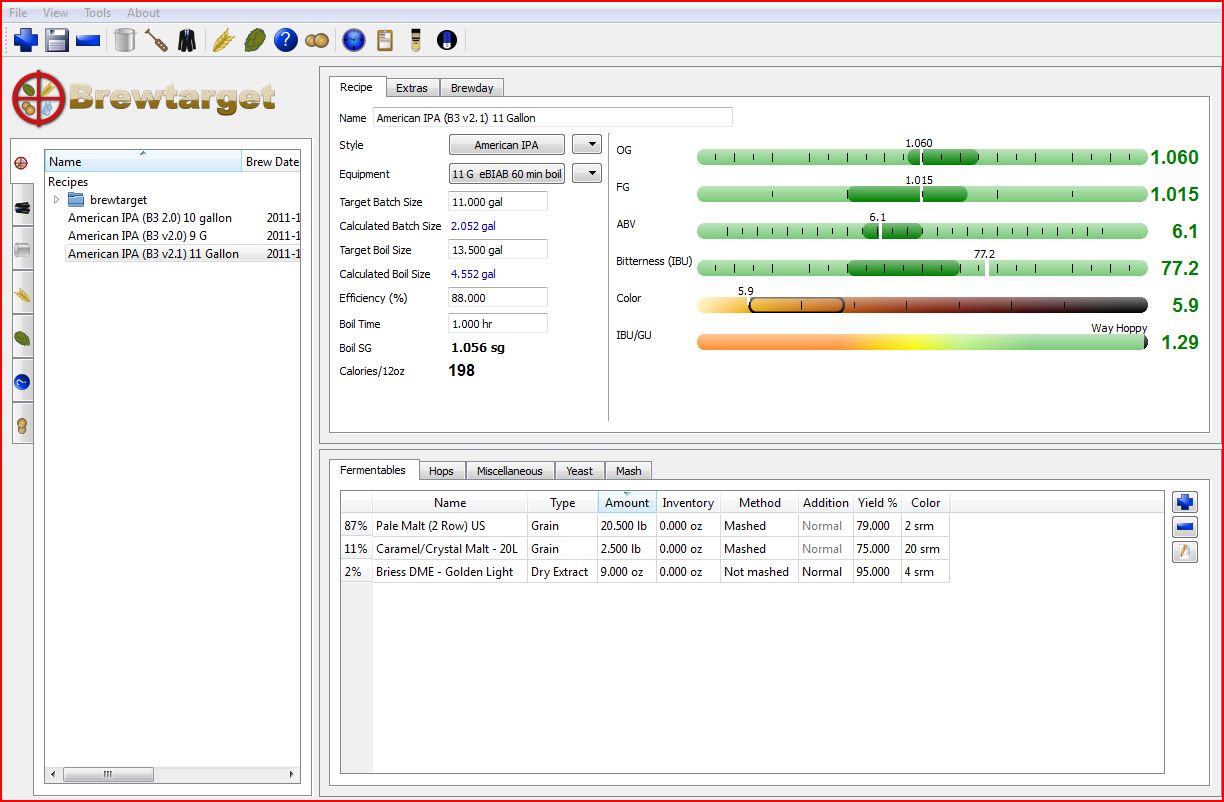

I mashed in and everything was going well... used iodine to test for complete conversion) Recipe called for 9 ounces of DME to get the OG I wanted in the limited volume of the kettle.. It didn't raise it enough to get to the OG I was after so I added more... My mash efficiency was down from the last time (was 88% before, this time was more like 82%), possibly because of the untreated rinse water, so I added more DME, and still didn't get where I wanted, but didn't want to keep pouring that expensive stuff in there after I had put in about 18-20 ounces...

So my OG and FG were going to be slightly lower... Recipe predicted .060 OG and I was around .056 -.057... So adjusting for those numbers when I test to see if the beer is finished...

I added 1 tsp of Wyeast nutrient to the boil ten minutes from finish, and then added the yeast (2 packs of US-05) to the wort that I had collected from the system (after I pumped all I could to the fermenter) to pour into the fermenter (ie what was still in the pump, left in the chiller and lines, etc.).. pitching temp was around 64 degrees (a couple three degrees lower than I was shooting for, but I'm still getting to know the system).. I set the fermentation chamber at 68 degrees...

I ran the inline oxygen at 4 lpm for about two and a half minutes as it was being pumped into the fermenter, then shut it off...

Hooked up the airlock, cleaned up the system and waited...

Woke up the next morning and 'nada'.. was disappointed... Checked several more times that day and still nada... I failed again, no ferment... I raised the temp of the ferment to a bit under 70 degrees (21 celsius) and left it alone...

So I figured the only thing left that could be the problem was that the grain was just too old (been stored between 3-4 years)... I figured I'd wait a few days to see if it ever took off and if not, dump it and go buy some fresh grain and try again... I had done everything else that I could think of to help the ferment...

So, I was bummed, but it was what it was..

Went out next morning, and viola, I could see through the side of the Speidel fermenter that the wort had changed color to light gravy color and the air lock was motorboating along just fine... Yippee! Now this is what I expected to see the last time I brewed! Just took a lot longer to take off than I expected.. That was Monday morning...

Just checked again (Wednesday afternoon) Gas production has slowed way down, and the color is still light gravy colored so it's still in primary.. It appears I'm getting a full primary and it will finish fermenting... I'm gonna have beer this time! Yippeee!

So glad!

So now I'll wait till after primary is done and the color darkens again and will take a reading.. Probably bump the temp up a little then too.... Then let it finish fermenting plus some extra time to condition and keg it!

So... SUCCESS!

Man, I never had so much trouble before, but the system is now more complex and there's a learning curve getting to know it's quirks and adjust for them...

I'm just glad I'm gonna have beer this time as opposed to pseudo beer that I had to mix with bottled beer to make drinkable.... and of course not have to dump out all that wort after all the work and expense of making it..

Now, on to dialing the process in, and then 'experimenting' using minor, documented changes to get the 'perfect brew'... and of course other recipes even styles...

Finally, after all that time, money, and work building it up, the new system produced...

I am happy!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)