nspaldi0

Well-Known Member

Finally beginning the initial stages of the brewery. It will be based on a similar cart style 2-vessel system like board member Resslerk has posted. I'll be using 240, so I've started with the spa panel. I'm not electrically minded, but I have studied enough here and figured I could get more than enough good help from this great forum to build this simple electric brewery.

To start, I'm using a 3 prong dryer outlet that is fed from a 30 amp breaker in the main panel. I purchased the 50 amp spa panel and will use a dryer cord to wire into the spa panel. I'll then mount a four wire plug in the spa panel enclosure like others have done.

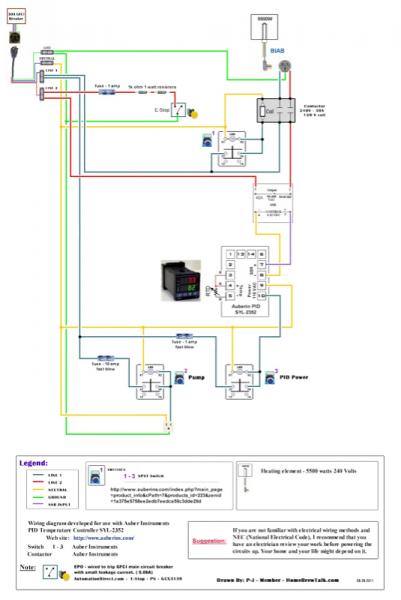

Here's my first of many questions.1) I wired the incoming dryer cord (10/3 cord, 120/250v) according to PJ's spa diagram as shown in the picture below. Should I have taken the ring terminals off and just used bare wire or will it be fine to leave the ring terminals on? 2) Can I use 10/3 wire to wire the 4 prong outlet that will supply the control panel?

Thanks for the help! I've been trying to start this since last November but life got in the way. Feels good to be building another brewery.

To start, I'm using a 3 prong dryer outlet that is fed from a 30 amp breaker in the main panel. I purchased the 50 amp spa panel and will use a dryer cord to wire into the spa panel. I'll then mount a four wire plug in the spa panel enclosure like others have done.

Here's my first of many questions.1) I wired the incoming dryer cord (10/3 cord, 120/250v) according to PJ's spa diagram as shown in the picture below. Should I have taken the ring terminals off and just used bare wire or will it be fine to leave the ring terminals on? 2) Can I use 10/3 wire to wire the 4 prong outlet that will supply the control panel?

Thanks for the help! I've been trying to start this since last November but life got in the way. Feels good to be building another brewery.