Don't unplug stuff that's drawing significant amps (general advice).

Respectfully, doesn't this contradict the advice in the rest of your post to go with a plug/unplug route? Or are you saying unplugging/re-plugging is probably fine if not done too frequently?

It jumps out to me because there are definitely some horror stories out there of fried receptacles due to bad contact with the plug, to the point that many folks recommend hardwiring EVSEs/chargers. I wouldn't personally go that far, but I do think extra diligence is warranted for EVSEs. Gently unplugging once or twice a month would probably be fine for years(?), but more often than that would raise an eyebrow for me. It seems the higher amperage plugs aren't designed with the expectation of frequent plug/unplug cycles (what do you mean you're not taking your welder/brewery on vacation with you?). You also don't want to accidentally unplug a live 10kW connection if you forget the car is actively charging.

Plug wear-and-tear is a big deal because EVs are one of the few "consumer appliances" that can max out a circuit continuously. The Ford Lightning would pull 40amps straight for over 10 hrs if it's doing a 0-100% charge and a more mainstream VW ID4 would be over 6hrs, so plenty of time to make a loose connection hot. (Realistically you'll never actually charge from 0-100 but the point remains.)

Even our brewing rigs pale in comparison to the constant power draw since boils don't require full power and ramping up to mash or boil is usually shorter than an hour.

Obviously, I won’t be using both at the same time. I know this isn’t the proper way, but is this a reasonable way to do this? Other ideas?

I would encourage you to double check the "this isn't the proper way" statement there; it seems the NEC allows it and they're the experts.

I am not an electrician but it seems reasonable to me. In a scenario of "non-coincidental" loads ultimately going back to a single breaker, that breaker *should* trip if you accidentally overlap the loads. On the other hand, the failure path for a worn out plug is the receptacle/plug melting or catching on fire; there's no safety mechanism to alert you or stop something from failing further.

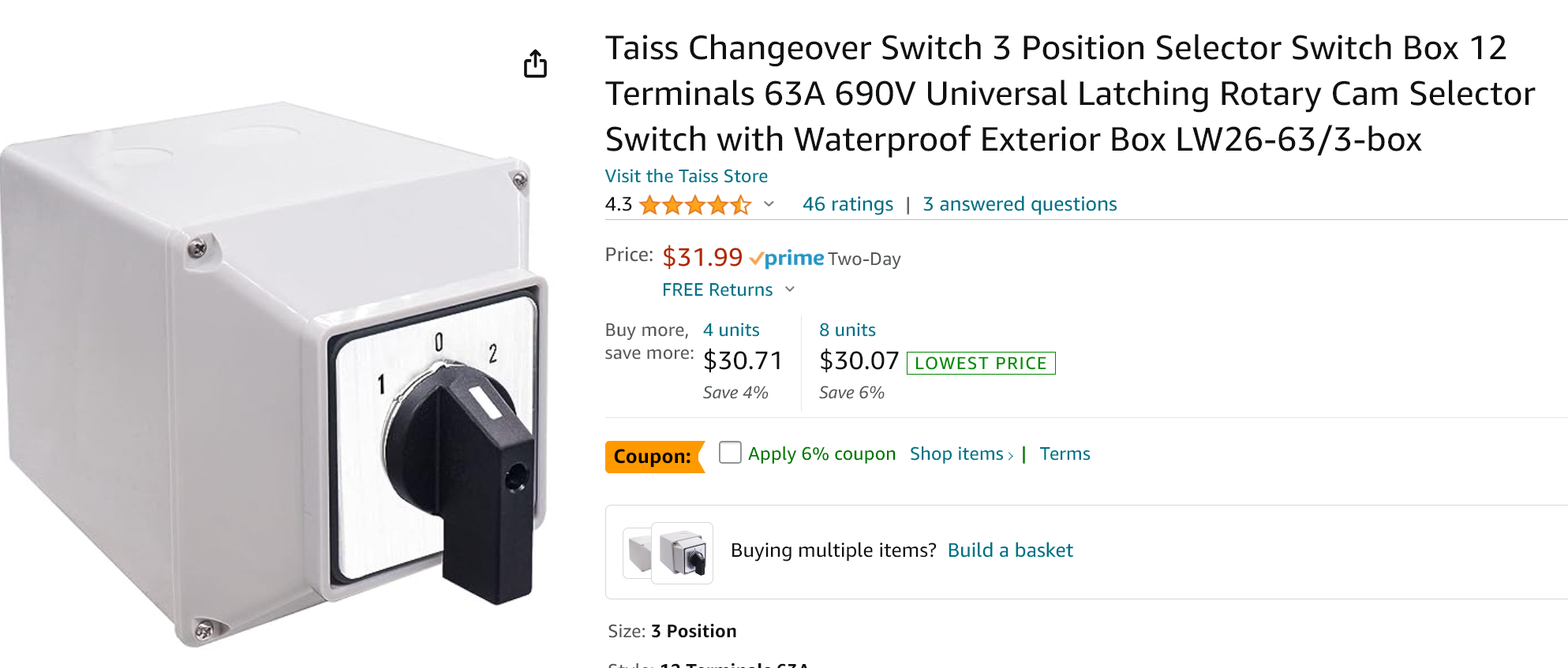

To your "other ideas" question: there are options to ensure you can't overlap the loads on a single circuit. Dryerbuddy is a "smart" device that can do it automatically and I think there might be physical transfer switches you could use to ensure you don't accidentally activate both simultaneously.

Lastly: people tend to overestimate the charge capacity they need for their car. Maybe you've already done the math and know you need 40amps to recharge for your scenario which is fine, but if you haven't, don't discount slower speeds. If your car is parked for 80+ hours a week at your house, even on 120v 12amp outlet, that's 300+ miles of charge for an average EV (or 200+ for an F150 Lightning) per week. Just something to consider if you already have a convenient 120v outlet that you can dedicate to EV charging where you park.

Disclaimer: I am not an electrician. Consider this free opinion to be worth what you paid for it.