chunkychicken

Active Member

- Joined

- May 8, 2016

- Messages

- 43

- Reaction score

- 9

So, I recently bought a Fermentasaurus Snub Nose to start brewing cider and beer with. Having done barrel brews, carboy brews and shake brews (shake that bottle for me, shake that bottle for me, come on now!), changing to pressure was something different. I'm not going to pretend I know anything about it, I just loaded in the mix, the water, the yeast & nutrient, pitched it, mixed it and planted it somewhere out of the way.

I didn't do a lot of research before hand, nor did I look up any recipes; I'm a chuck it in and see what happens kind of person. Prepared, right? Well, I've done a few batches before, so I knew what I was getting myself into. From the research I did do, the main benefits of fermentation under pressure are:

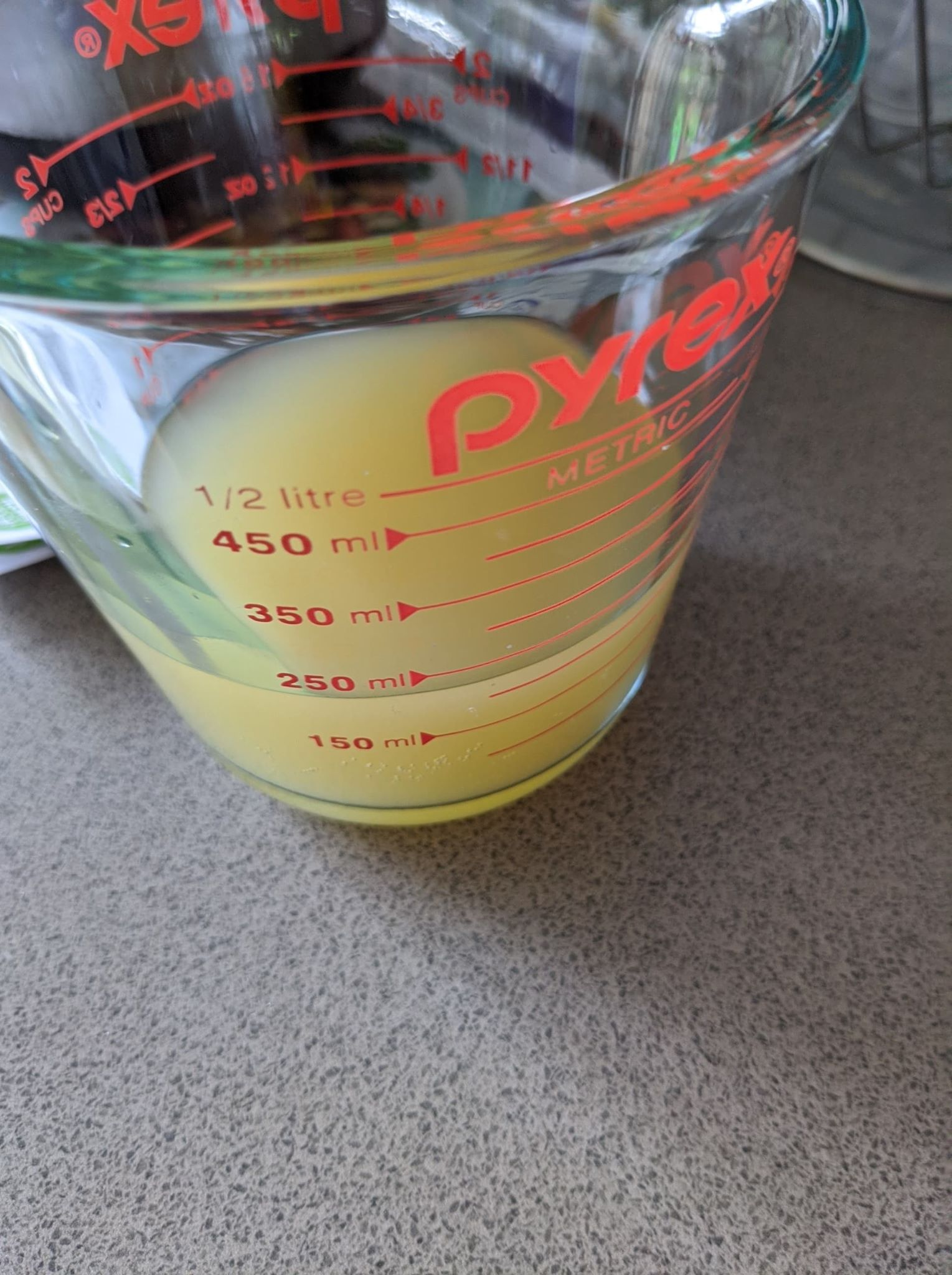

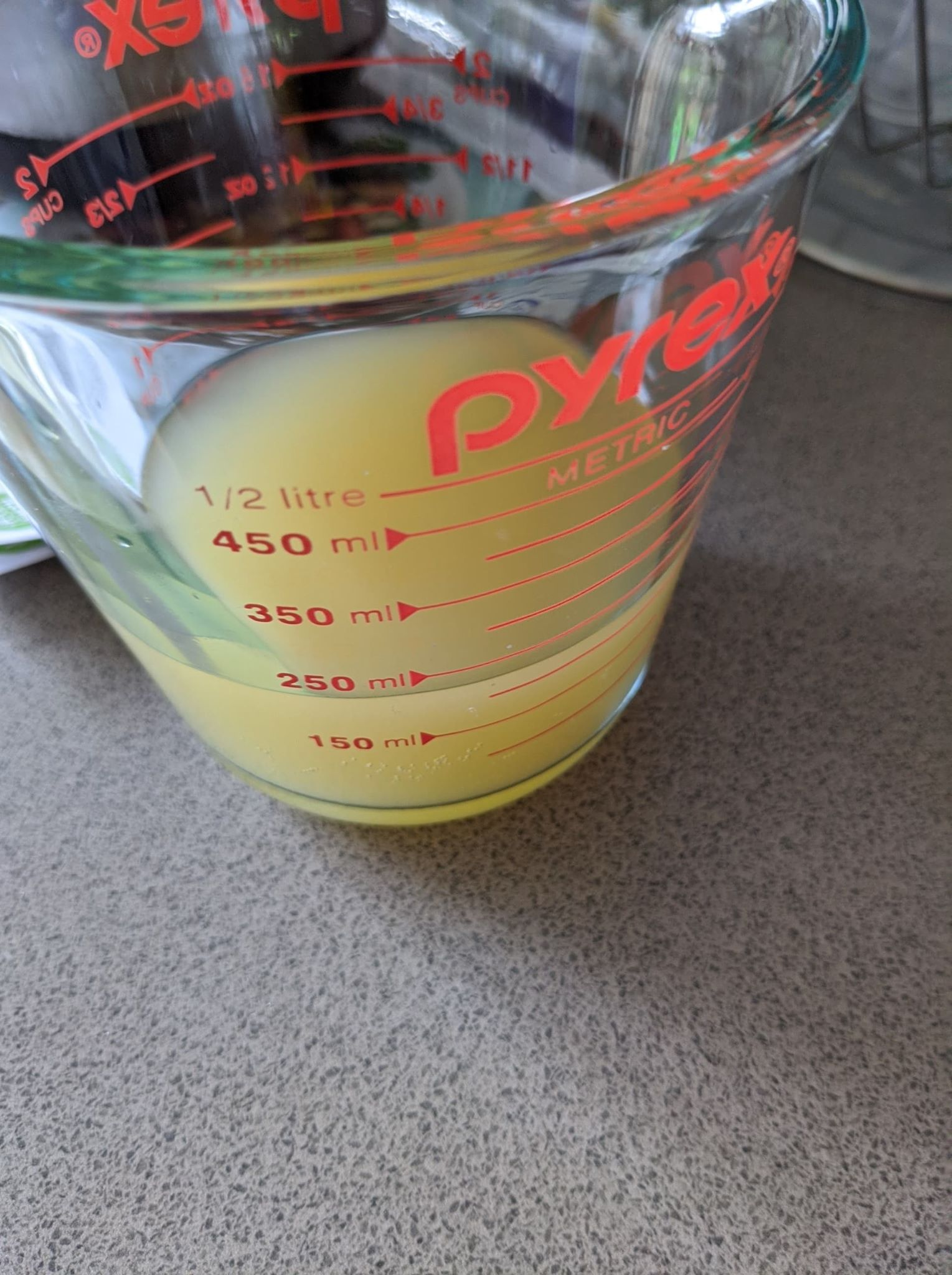

SG? Didn't take a read, but I estimated it to be approximately 1054 based on current gravity (1016). I did pitch 1kg of standard white sugar before pitching. I tested it 5 days later, already drinkable, smells great, retains some of the sweet flavour and has already reached 1016 (5%). I can't really find much information about the strain of yeast in the kit, but here's the details:

Brigalow apple cider kit, (1L + 17L water makes 18L)

5g Saccharomyces cerevisiae

4g yeast nutrient

WLP664 would be the closest yeast by name that you can buy, and has an attenuation of 85%, meaning the finishing ABV for this should be around 5.6%~5.8%.

Initial thoughts

Fermentation started fast, within 24 hours, with most activity around 60 hours in, lasting for a good 24 hours. It's 5 days in and the activity has almost stopped. I chucked a spunding valve on the fermenter today and it read 5psi, didn't budge. There's still some activity, but it's clear primary fermentation is just about done. The last time I tried cider after 5 days I tried not to throw up. Not the case with this. It's sweet, has a light tang and is already very drinkable. It's cloudy and needs time to clarify, but to be honest, that's not going to happen, even with the delicious beer next to it.

There's a lot of reviews that absolutely dump truckloads of muck on Brigalow, and I'm not going to say its the best, but for just throwing it all in together and not showing a great deal of care to the process (I did clean and sanitise until I was physically sanitised myself), so far it's turned out damn good. It's an extremely cheap brew ($15 for a tin) that can make 18L (4.5gl) of drinkable cider that you won't instantly hate.

Would I use this process again?

Yes, absolutely. I've found it to be easier to use, produces a cleaner brew, and at no time during the brew process did I get any rhino fart smells, that nail polish nasty alcohol, or any yuck side effects of the brew, especially build ups of so2. Also, while retaining pressure in the vessel, I can do a liquid pour without exposing to oxygen, straight from the liquid out valve. Winning.

I didn't do a lot of research before hand, nor did I look up any recipes; I'm a chuck it in and see what happens kind of person. Prepared, right? Well, I've done a few batches before, so I knew what I was getting myself into. From the research I did do, the main benefits of fermentation under pressure are:

- shorter fermentation times

- ferment at higher temperatures without the risk of esters, bad smells and bad tastes

- alcohol can be pre-carbonated

- head room no longer matters because of co2 pressure

- vitually no contact with oxygen after pitching, if you purge oxygen with co2

SG? Didn't take a read, but I estimated it to be approximately 1054 based on current gravity (1016). I did pitch 1kg of standard white sugar before pitching. I tested it 5 days later, already drinkable, smells great, retains some of the sweet flavour and has already reached 1016 (5%). I can't really find much information about the strain of yeast in the kit, but here's the details:

Brigalow apple cider kit, (1L + 17L water makes 18L)

5g Saccharomyces cerevisiae

4g yeast nutrient

WLP664 would be the closest yeast by name that you can buy, and has an attenuation of 85%, meaning the finishing ABV for this should be around 5.6%~5.8%.

Initial thoughts

Fermentation started fast, within 24 hours, with most activity around 60 hours in, lasting for a good 24 hours. It's 5 days in and the activity has almost stopped. I chucked a spunding valve on the fermenter today and it read 5psi, didn't budge. There's still some activity, but it's clear primary fermentation is just about done. The last time I tried cider after 5 days I tried not to throw up. Not the case with this. It's sweet, has a light tang and is already very drinkable. It's cloudy and needs time to clarify, but to be honest, that's not going to happen, even with the delicious beer next to it.

There's a lot of reviews that absolutely dump truckloads of muck on Brigalow, and I'm not going to say its the best, but for just throwing it all in together and not showing a great deal of care to the process (I did clean and sanitise until I was physically sanitised myself), so far it's turned out damn good. It's an extremely cheap brew ($15 for a tin) that can make 18L (4.5gl) of drinkable cider that you won't instantly hate.

Would I use this process again?

Yes, absolutely. I've found it to be easier to use, produces a cleaner brew, and at no time during the brew process did I get any rhino fart smells, that nail polish nasty alcohol, or any yuck side effects of the brew, especially build ups of so2. Also, while retaining pressure in the vessel, I can do a liquid pour without exposing to oxygen, straight from the liquid out valve. Winning.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)