Hi, I am a new member here and fairly new to home brew. I am just about to rack my fermenter into bottles, this is the third kit I have done.

Already I am tired of sanitizing 30 odd bottles and have been having issues with some of my bottles not sealing and resulting in flat beer, I have no interest in solving this issue as I'd preferer to move onto kegging.

I brew IPA, I like to drink it at room temperature and I like a light carbonation if any (just not totally flat).

Having tired of bottling, I have bought 2 19L corny kegs. I have yet to buy the gas regulator and am having a devil of a job finding a supply of CO2 (Devon UK).

So, having a fairly inquisitive and problem solving sort of mind I have an idea I'd love to get your experienced feedback on.

The basic idea is that:

1. I cold crash my fermenter.

2. I dispense the beer into keg #1 with some priming sugar.

3. I place water, sugar and beer yeast into keg #2.

4. I attach the gas in of keg #2 to the gas in of keg #1

My theory is that the priming sugar carbonates the beer in keg #1. The CO2 generated in keg #2 is enough to allow me to dispense beer from keg #1.

What are peoples thoughts, has this been done before ?

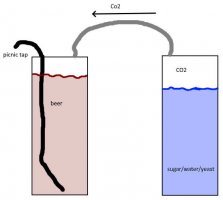

I have provided an illustration to further explain my plan.

I would greatly appreciate any and all feedback. Regards, Rick.

Already I am tired of sanitizing 30 odd bottles and have been having issues with some of my bottles not sealing and resulting in flat beer, I have no interest in solving this issue as I'd preferer to move onto kegging.

I brew IPA, I like to drink it at room temperature and I like a light carbonation if any (just not totally flat).

Having tired of bottling, I have bought 2 19L corny kegs. I have yet to buy the gas regulator and am having a devil of a job finding a supply of CO2 (Devon UK).

So, having a fairly inquisitive and problem solving sort of mind I have an idea I'd love to get your experienced feedback on.

The basic idea is that:

1. I cold crash my fermenter.

2. I dispense the beer into keg #1 with some priming sugar.

3. I place water, sugar and beer yeast into keg #2.

4. I attach the gas in of keg #2 to the gas in of keg #1

My theory is that the priming sugar carbonates the beer in keg #1. The CO2 generated in keg #2 is enough to allow me to dispense beer from keg #1.

What are peoples thoughts, has this been done before ?

I have provided an illustration to further explain my plan.

I would greatly appreciate any and all feedback. Regards, Rick.