- Joined

- Jul 29, 2021

- Messages

- 139

- Reaction score

- 150

I stand corrected! You are right. Where I worked before retirement we had power supplies that were Constant voltage output (120-165 Kv) and monitored the final output. If the output (photons) dropped the feedback would increase the current. So a resistive connection would just keep getting hotter and hotter. Sometimes I can't get my brain out of work mode and back to the theory mode.This sounds like you are saying that at constant voltage, if the resistance increases, then the current will also increase. This is wrong. Ohm's Law is: V = I * R, where V is voltage, I is current, and R is the resistance thru which the current flows. Ohm's Law can be rearranged as: I = V / R, which clearly shows that at constant voltage, if the resistance increases, the current decreases.

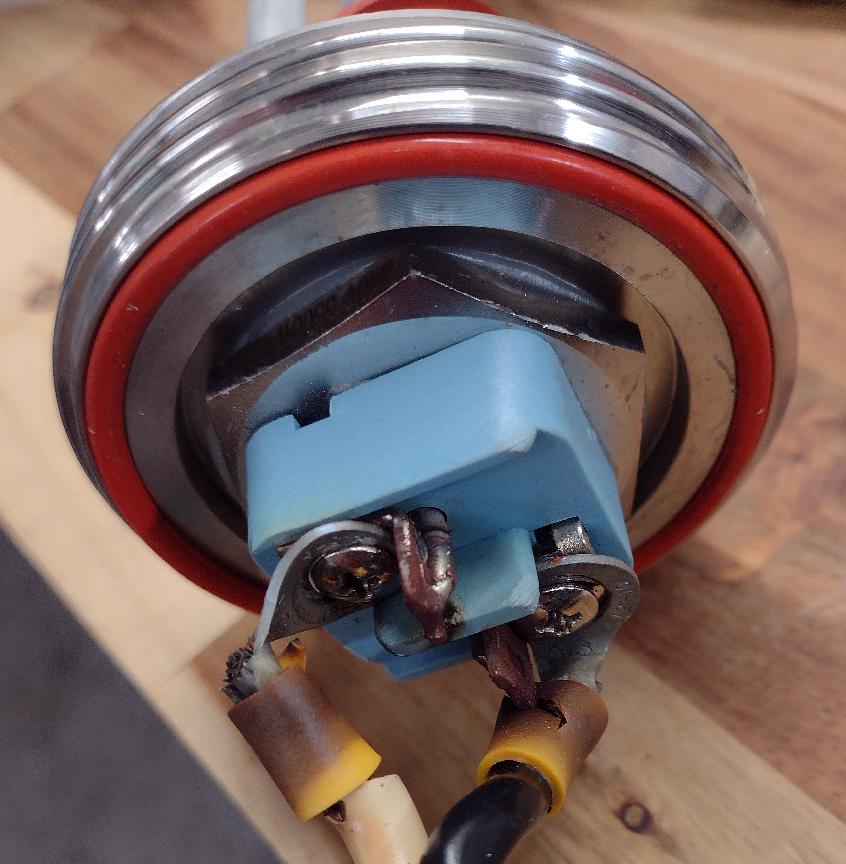

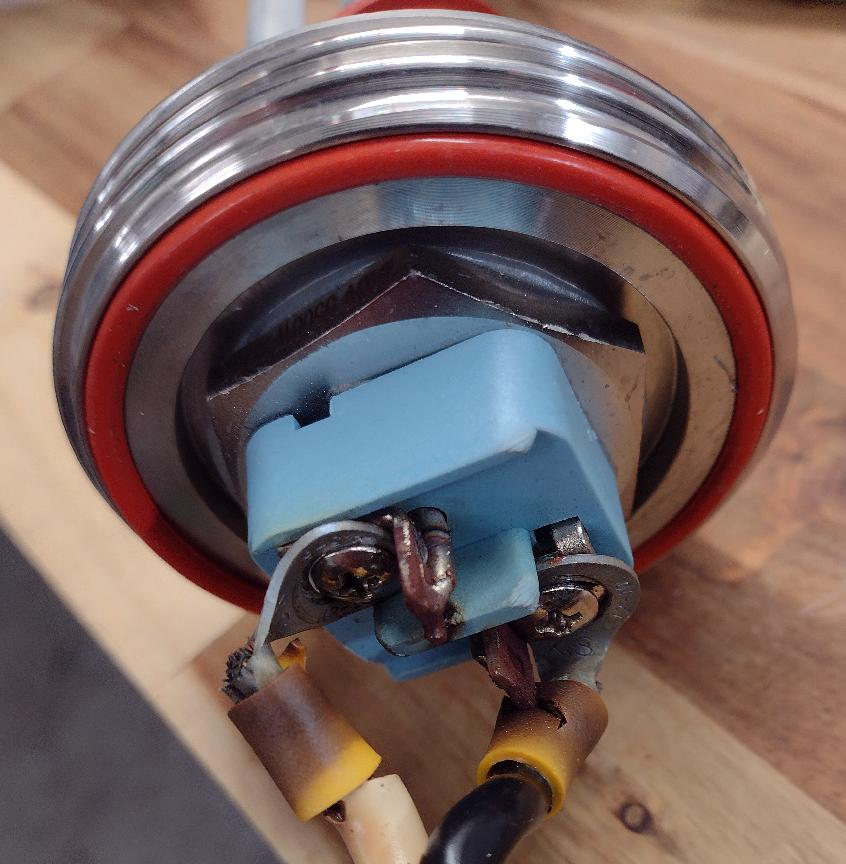

What you want to look at when it comes to localized heating is this formula: P = R * I^2, where P is power. Since the current flowing in any branch of a circuit is constant everywhere, you can break the circuit branch into individual pieces, each with their own resistance value. The heat generated in each of the pieces is then determined by the current and the resistance of the particular piece.

Let's look at a simple example:

The fixed voltage is 240V, and the branch of interest is two connections with a nominal resistance of 0.005 ohm (5 mohm) each and a heating element with a resistance of 10.30 ohms. The total resistance of the branch is 10.31 ohms, and the current flowing will be 240 / 10.31 = 23.28 A. Now, if one of the connections goes bad, and the connection resistance increases to 1.0 ohm, then the branch resistance increases to 11.305 ohms, and the current drops to 240 / 11.305 = 21.23 A. For the original connection, the heat generated in the connection will be 0.005 * 23.28^2 = 2.71 W. For the degraded connection, the heat generated will be 1.0 * 21.23^2 = 450.7 W, which is more than enough to overheat a small volume and burn the insulation.

Brew on

Thanks for catching that.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)