Thanks. I don't need to see the set temp all the time, but wouldn't mind getting a dual if it ran a 2nd device, or at least showed room temperature. The

tcqbn2006p listing states "The Controller can be set to control two separate devices at the same time.", which indicates this is possible, with 2 probes I guess? I prefer single controllers though 2 of them would be 3 times the price of a dual.

The explanation of how it works by mjmac85 was essentially correct, but a bit oversimplified. For both the dual stage unit that this thread is about (STC-1000), and the similar single stage unit, the display actually shows the temperature that the probe is reading, not the set temp you have programmed. The STC-1000 controls two devices at the same time, one heating device, and one cooling device, but only uses one temperature probe to do this. You have to program both a set temperature and a temperature differential. If the probe reads above the set temp plus the temp differential, the cooling device is turned on, and runs until the temp comes back to the set temp. If the temp drops below the set temp minus the temp differential, the heating device is activated, and stays on until the temp reaches the set point.

For example, if you have the set temp at 18.0C and the differential set at 0.5C, nothing will happen as long as the temp stays between 17.6C and 18.4C. As soon as the temp reaches 18.5C, the fridge will activate and cool until the temp comes down to 18.0. If the temps drops to 17.5C the heater will activate and stay on until the temp comes up to 18.0C. And FWIW the STC-1000 has a minimum temperature differential of 0.3C.

The PID you linked seems to be set up to operate the same way, and also only has one temperature probe input. The main difference is that it has two displays, one to show the temp sensor reading (upper display), and one to display the set temp (lower display). The relays on that unit are only rated for 3A, which is less than most fridges and freezers draw, and might require adding an external SSR. The relays on the STC-1000 controller on the other hand are rated for 10A.

Right, but stand alone where? I have seen quite a few controller project boxes online but none of them attached to anything. I've been wondering if one could be recessed in the wall, along with the regular outlets. I see now that the boxes would need to be turned around so the screw plate goes on front, or I could use a regular switchplate outlet box. The probe would be coming out but still it should look good this way. However would the controller get too hot in the wall?

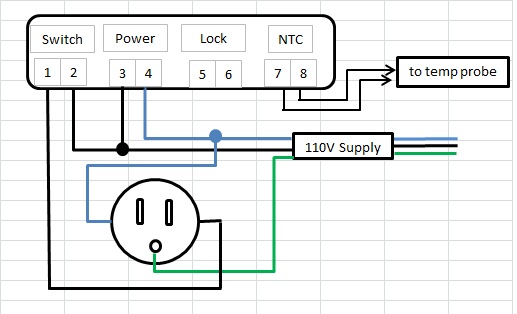

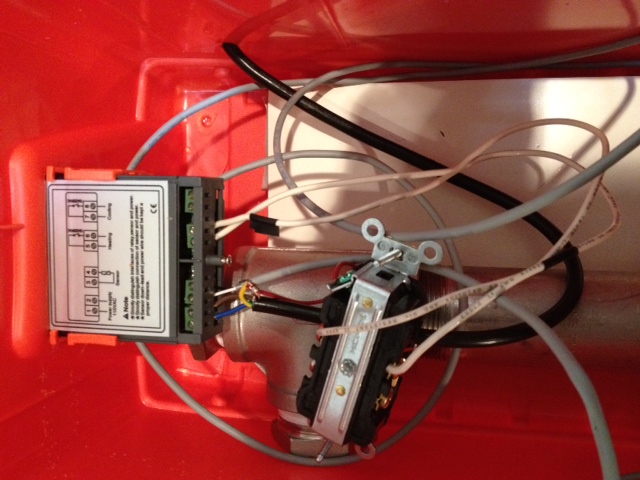

A lot of people place the stand alone unit on top of their fermentation fridge/cabinet, some simply tuck it out of the way behind the ferm fridge/cabinet, and some screw it to the wall or side of their ferm cabinet. The one for my keezer is built into the collar, but I set the stand alone unit for my fermentation fridge on top of the fridge. I don't see any issue with mounting the unit in a wall. It wouldn't get any hotter in the wall than it would in a small airtight project box. The mounting size is only slightly larger than a decora outlet, so you could do something like

this build, except install the box in a wall. You'd just need to drill a small hole in the cover plate for the temperature probe to come through. If you used an "old work" box you could mount it sideways so that the controller display is oriented properly.

Hope this helps.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)