ftlstrings

Well-Known Member

Sorry, guess it only goes to 35, good enough I think, unless you like beer-cicles.

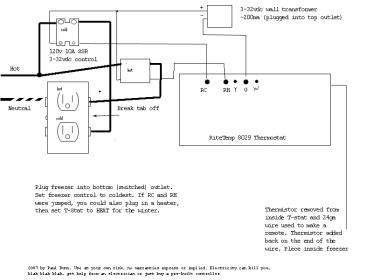

What is the voltage output of the 6020 (sent to the SSR)?

Sorry, guess it only goes to 35, good enough I think, unless you like beer-cicles.

In this SSR application, is a heatsink required? I can't tell if you have used one or not. If you have, where have you placed it?

Cheers,

Rhino

...However, I am finding that if I can get the freezer to switch on the first time, if I set the thermostat lower than the internal temperature, and then can get it to switch off if I raise the target temp. However, I cannot get the freezer to switch back on if I drop the target temp again. Is there some sort of delay built into the thermostat?

Johnson Controllers (A19 type) can be had from ebay for < $30. That's where I bought mine. You do have to supply your own power cord, but that's it.

Its good you can do all of that stuff but those costs add up and that makes less time for the pretty stuff. For 70 bucks, why not buy the Johnson electronic (not mechanical) control with adjustable time-delay and differential and all you have to do is plug it in (and drop the probe inside). We are selling more and more of these. It takes 3 minutes to read the instructions and about 1 minute to program it.

is it possible to make this into a 2 stage temp controlleR?

East enders

is it possible to make this into a 2 stage temp controlleR?

East enders

hmmm, not sure what you are monitoring. Mine was a beer meister using a freezer. I can tell you that in my case, it was nuts on. I used a 4 degree range of 33 to 37, set point 35. (I like it cold) -and it never drifted outside of those parameters and tended to display set point temp most of the time-otherwise somewhere between 34 and 36. Make sure your probe connections are tight on the control. (apparently mine wasn't tight enough when I received/installed it-froze my beer. One other froze episode-make sure no one forgets to re-insert probes if you are leaving them hanging on the wall without anchoring. In short, no problem other than human error. (I didn't vent or fan the box.)Sorry for the bump, but I am working out my temperature controller right now, and it is quite similar to your build. You say that the SSR does not require a heat sink for this application. Just wondering if you've noticed how hot it actually gets? I am doing a dual stage controller, so I will have two SSRs in the enclosure, obviously not both running at the same time.

Trying to figure out if I might want to wire a fan into the enclosure itself, or possibly just vent it. Just paranoid about anything that can run in an unattended state.

hmmm, not sure what you are monitoring.

Nice project. Just one tip for the future when wiring stuff like outlets. Wrap the wire in the direction you are tightening the screw. This will pull the wire into and around the screw and apposed to try and twist itself out when you are tightening the screw down over the wire. AKA, bring the wire looped from the left to the right instead of right to left like in the picture above.

Specifically looking as to the temperature swings on the SSR itself. Due to it switching AC, my concern is actually that the junction box, itself, might become too hot as opposed to the contents of the fermentation chamber it will eventually be installed on.

The comments about leaving it unattended are related to not wanting to head out for the weekend and come back to a melted down junction box from excess heat build-up, or worse.

i really wouldn't be concerned about it, but it's totally up to you if you want to put a vent/fan of some sort in there. mine has run fairly continuously for the last 6 months off and on and even when it's been controlling a heater for a week straight, when I go to move it, it only feels like ambient temperature. the plate that covers the junction box has a little opening on one side, so that sort of acts as a vent I guess... but it's never felt hot or even warm to the touch and like I said, I use this fairly often.

Can someone please send me the complete instructions?

Augie