I obviously had to print some tap handles. I looked and looked, and all the handles I found were just not designed well, and were kinda boring. Then I found this:

http://fermware.com/3d-printed-tap-handles/

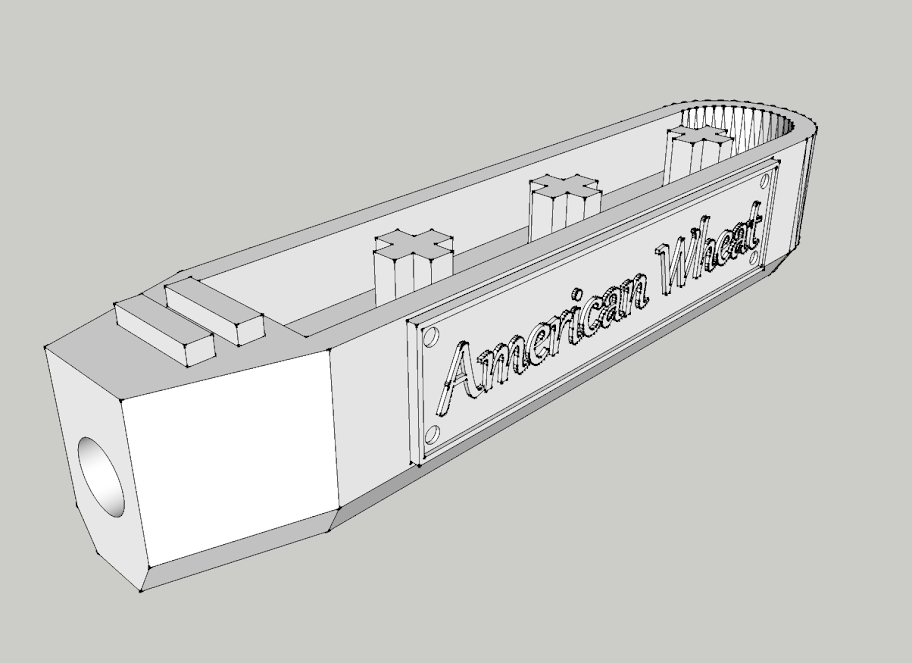

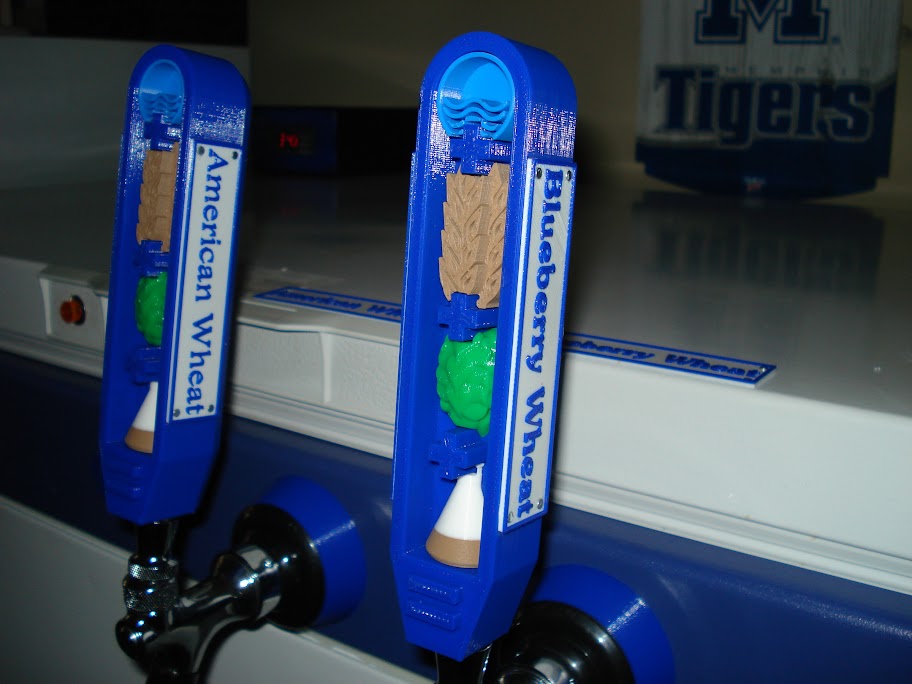

I loved the handles, but I couldnt leave it unmodified, right? The files that the guy put on thingiverse just had his website on the side. I had seen some of his own handles that he made, had placards for different types of beer. Most of them he made specially for local breweries and pubs and such, and his placards were permanently glued on. Since these handles take some work to print and construct, I didnt want to print a new handle for every type of brew I would be brewing in the future, so I decided to remix his design by removing his website, and adding magnetic placards. Basically i put some holes for magnets in the handle, and holes for thinner magnets for the placard, and I just superglued them in.

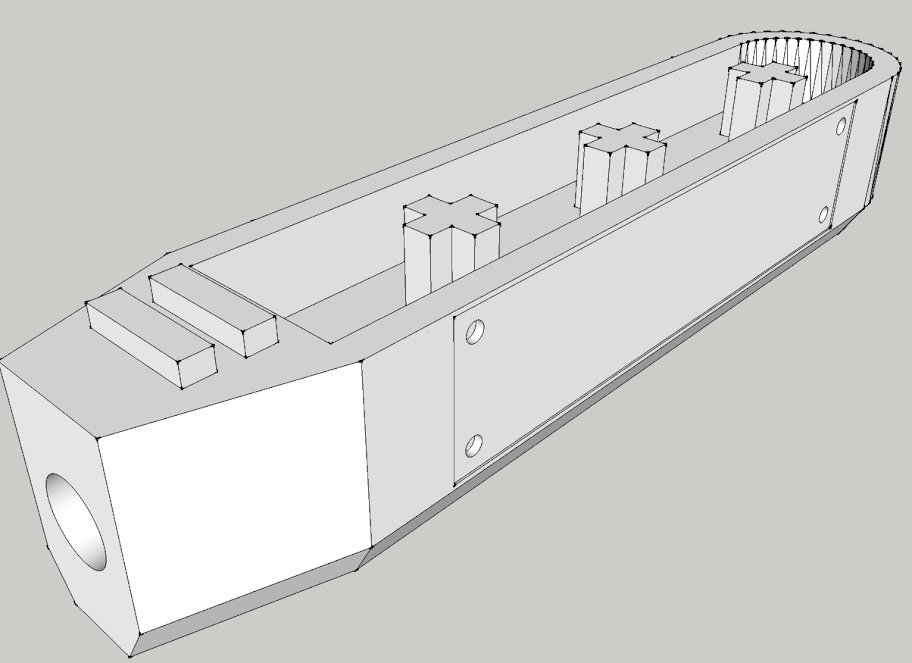

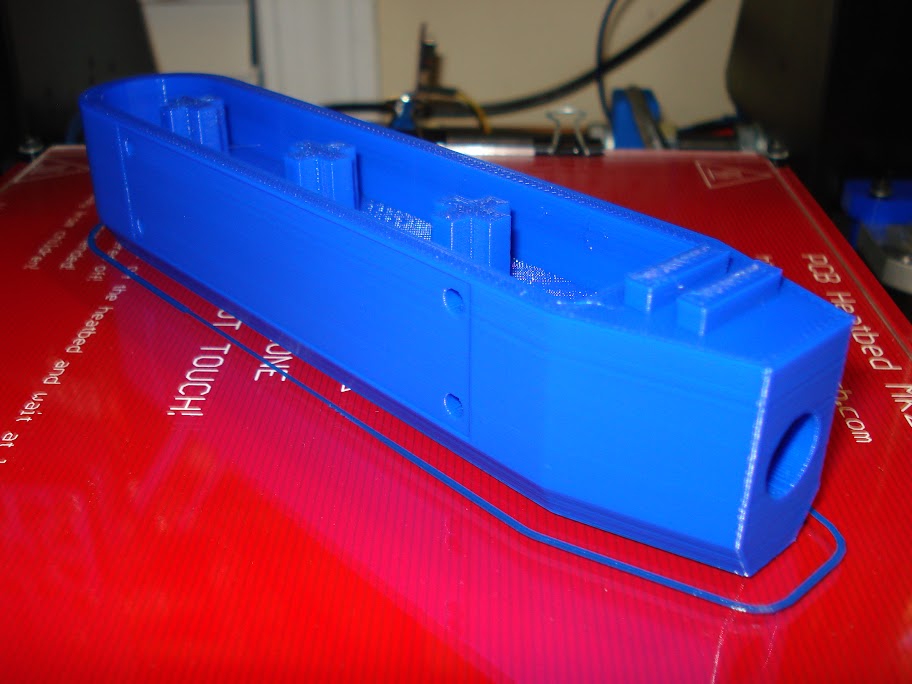

Bare tap handle, with recessed rectangle for placard, and magnet holes:

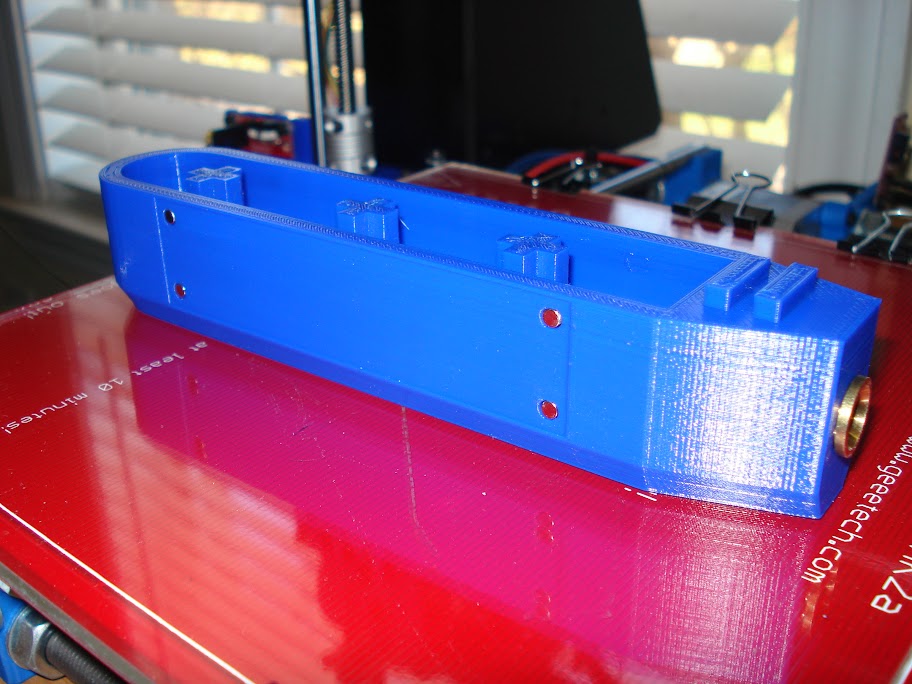

Base tap handle, with placard added.

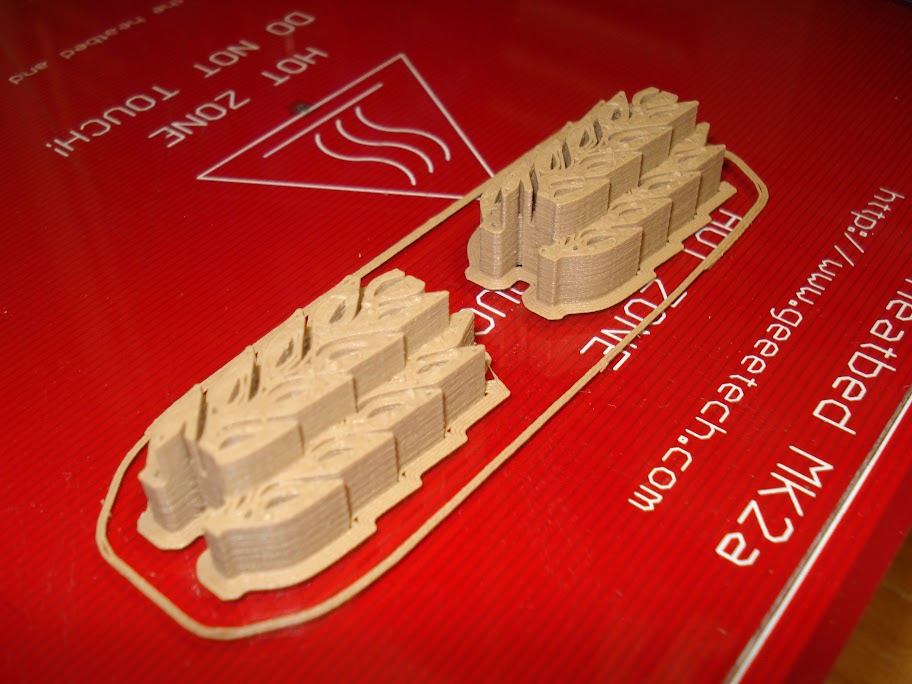

I also needed to adjust his design to fit the brass thread inserts I bought from grainger. I nailed the fitment in 2 tries, using little test cubes.

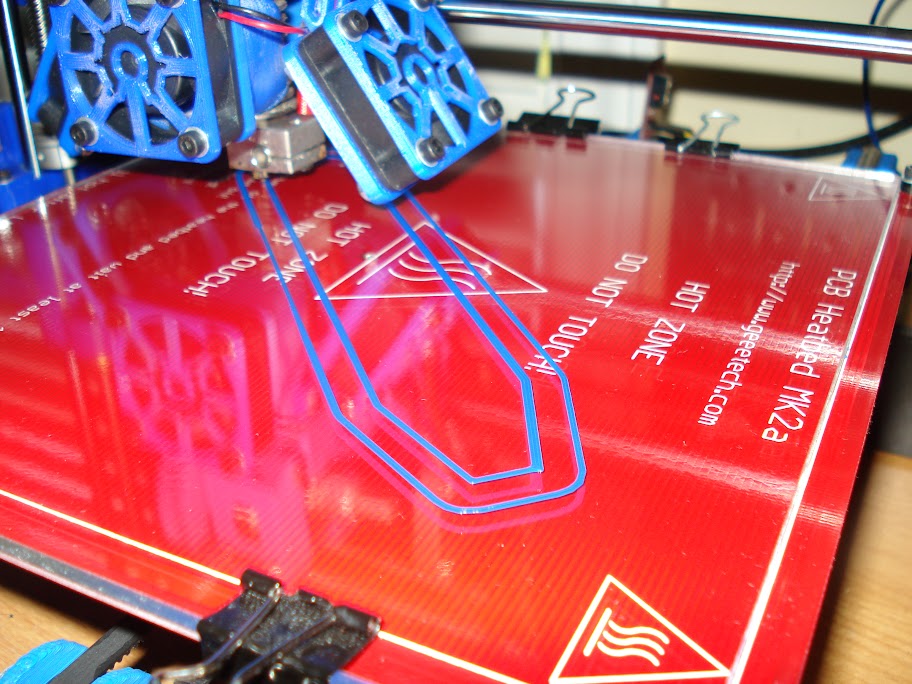

The fun begins

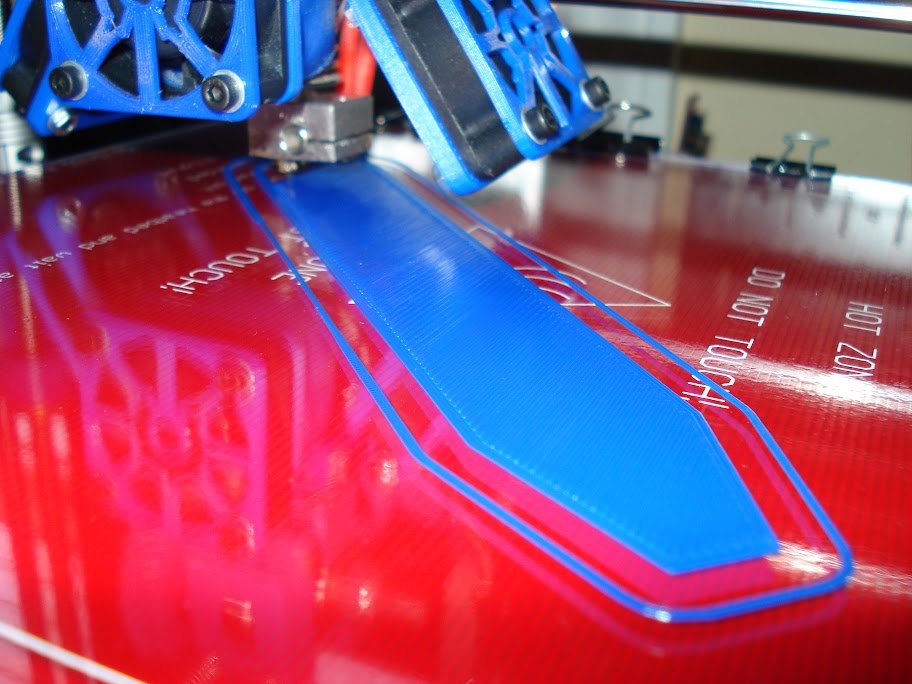

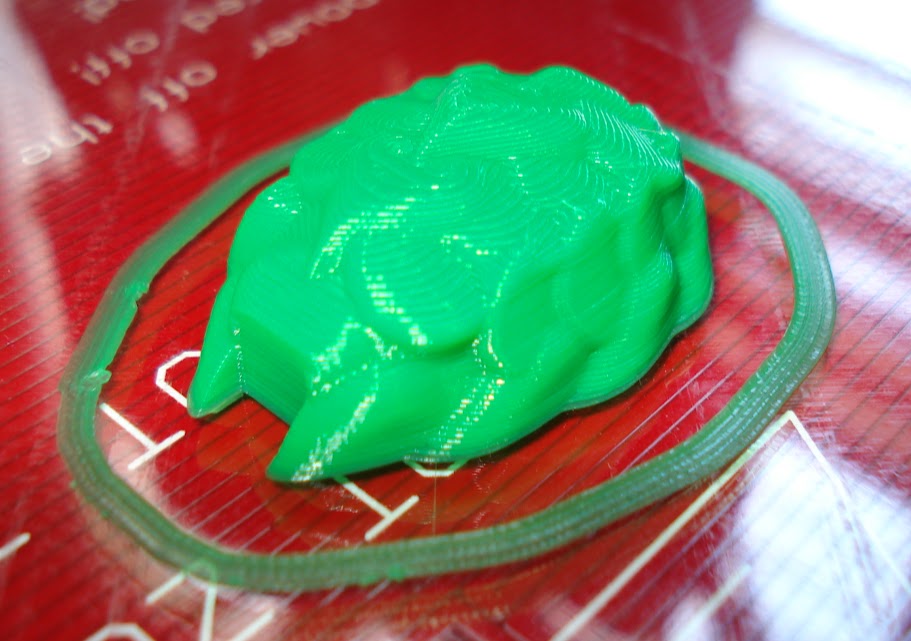

First layer complete

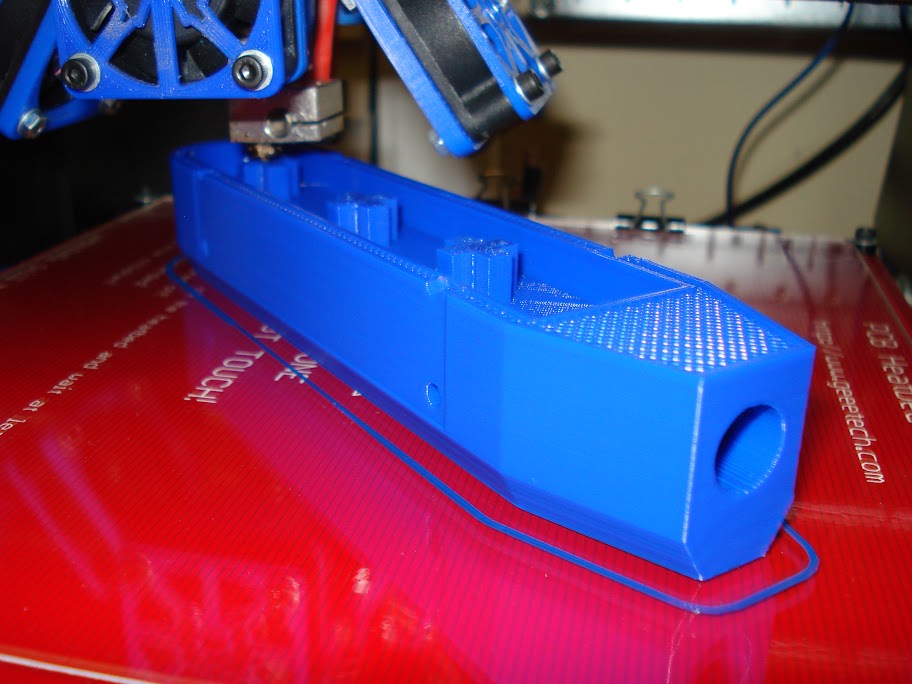

Almost done

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)