spaceyaquarius

Well-Known Member

You can easily save $400 by converting your own Danby mini-fridge into a double tap Kegerator. I kept looking for Kegerators that were already converted (on Craigslist you have the risk of a scam or non-working fridge), and off Amazon you have a total of around $800 for a double tap Kegerator with this exact Danby 440BL 4.4 cubic feet model. I just slowly bought the equipment needed from Amazon/Lowes until I was ready to spend one weekend day completing the project. You don't need a power drill, nibbling tool, any movement of refrigerant lines, or even DIY experience if you get this model. If I can do it, so can you in 20 easy steps!!!

Equipment Required:

• One Danby brand 4.4 inner cubic feet, model number DAR440BL mini-fridge = $200

• Two 5-gallon Cornelius kegs outer aluminum and inner stainless steel = $120-$180

• Double-tap stainless steel draft tower 3” ID w/Perlick 525SS faucets = $100-$120

• Vice grips/box knife/hammer/allen wrench/electrical tape/wire cutter = $25

• New CO2 tank (filled) = $90-$100 (with refills at $10-$20 each)

• Four MFL ball lock quick-connects w/3/16" male barbs = $32

• Two sets of 10 ft., ¾” inner diameter lines = $22

• Double CO2 regulator + plumbers tape = $100

• Drip tray for the top of the fridge = $40

• Progressively larger screws/ nails = $5

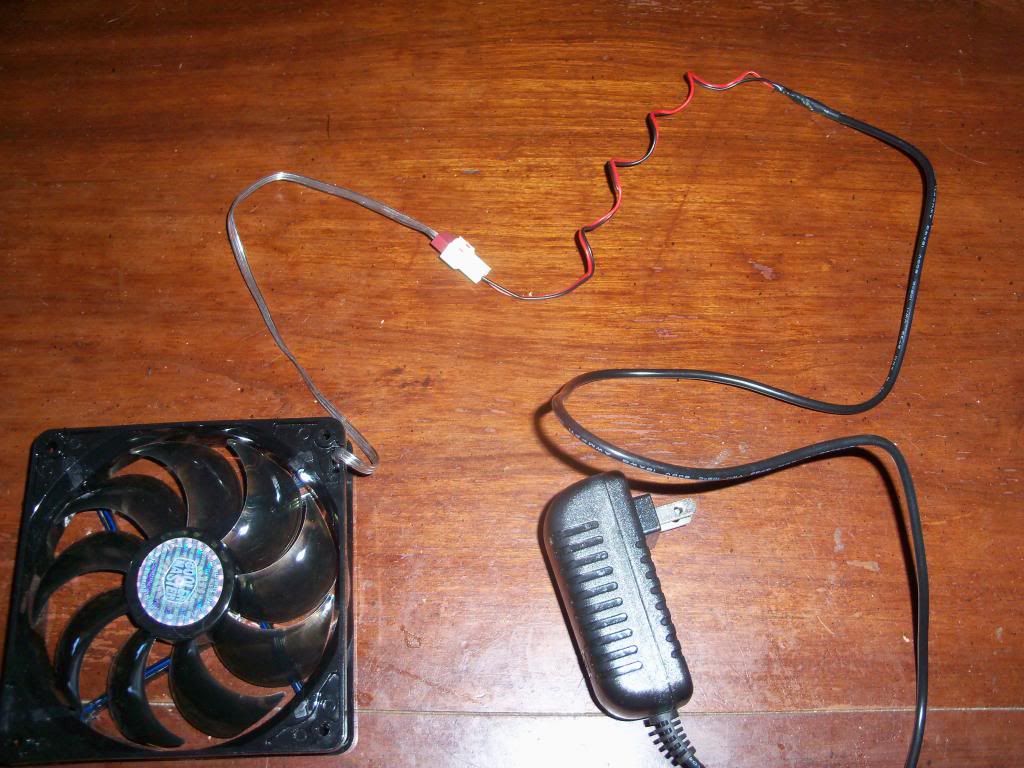

• PC fan with cool blue lighting = $15

• Two 5/16" ID vinyl gas lines = $20

• Waterproof aluminum tape = $7

• Power converter AC/DC = $4

• Two male to male barbs = $6

• Four fender washers = $2

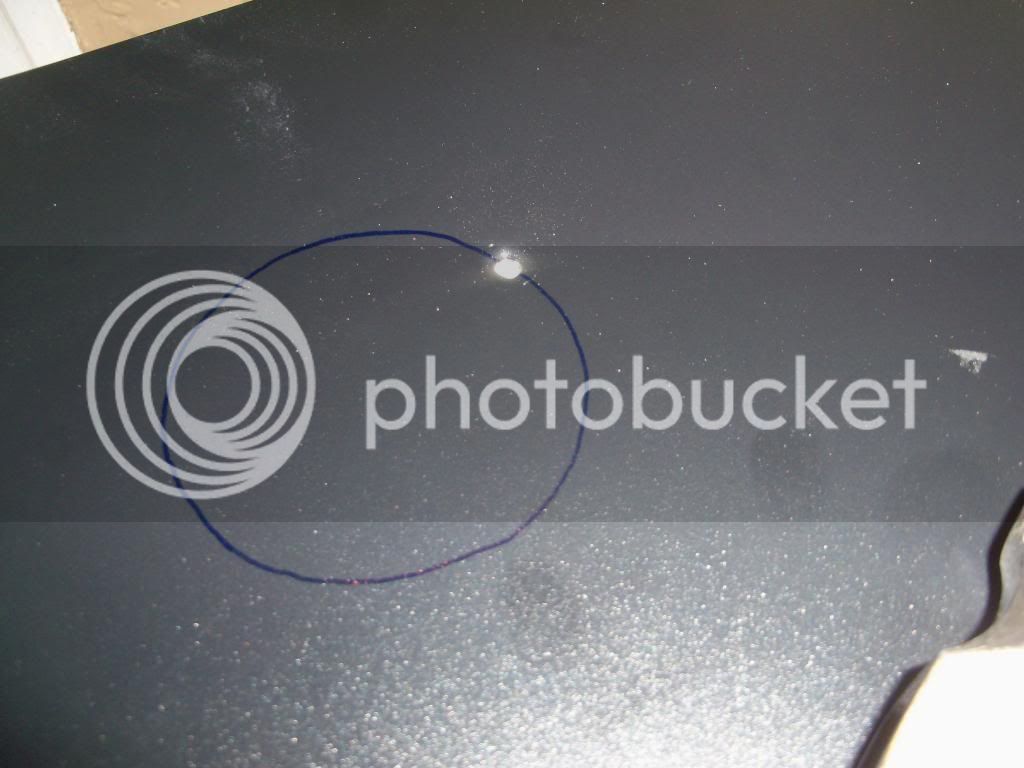

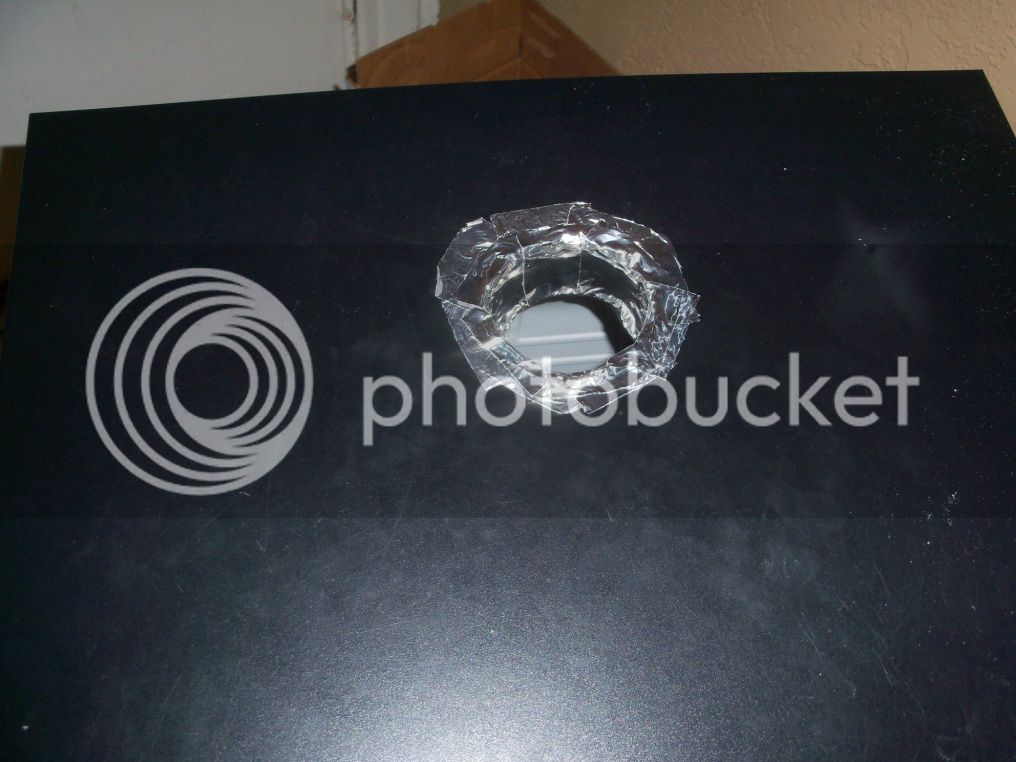

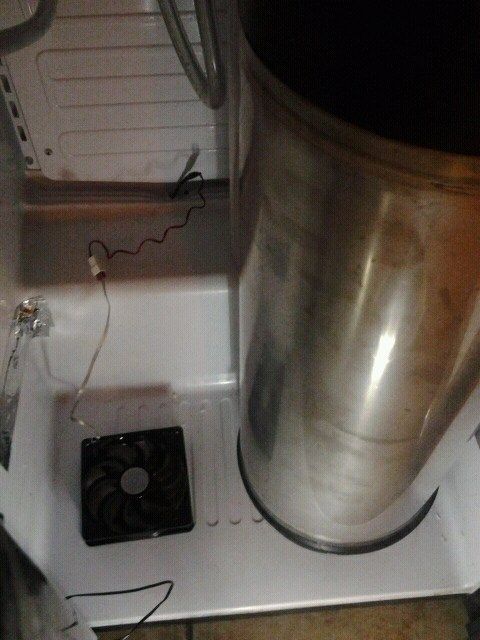

01 – As of 2013, the Danby model number DAR440BL can be purchased from $120-$180 from Amazon, Wal-Mart or Lowes. If you have Amazon prime, you can get free 2 day shipping. Home Depot sells a Danby Kegerator built from this exact model for $800. You will be able to save about $400 building your own Kegerator. There are other Danby models which have an inner freezer that drops down vertically from the top of the mini-fridge which cannot be disconnected. You will need the model that has the freezer component attached to the back wall of the mini-fridge (see photos below). After reading several Danby "how-to" conversion instructions before that were based off of the older Danby 440BL which is not in production anymore, I thought that a newer procedure needed to written. The newer version of this model is easier to convert than the earlier versions (of course you should check your model against the photos below to make sure).

Equipment Required:

• One Danby brand 4.4 inner cubic feet, model number DAR440BL mini-fridge = $200

• Two 5-gallon Cornelius kegs outer aluminum and inner stainless steel = $120-$180

• Double-tap stainless steel draft tower 3” ID w/Perlick 525SS faucets = $100-$120

• Vice grips/box knife/hammer/allen wrench/electrical tape/wire cutter = $25

• New CO2 tank (filled) = $90-$100 (with refills at $10-$20 each)

• Four MFL ball lock quick-connects w/3/16" male barbs = $32

• Two sets of 10 ft., ¾” inner diameter lines = $22

• Double CO2 regulator + plumbers tape = $100

• Drip tray for the top of the fridge = $40

• Progressively larger screws/ nails = $5

• PC fan with cool blue lighting = $15

• Two 5/16" ID vinyl gas lines = $20

• Waterproof aluminum tape = $7

• Power converter AC/DC = $4

• Two male to male barbs = $6

• Four fender washers = $2

01 – As of 2013, the Danby model number DAR440BL can be purchased from $120-$180 from Amazon, Wal-Mart or Lowes. If you have Amazon prime, you can get free 2 day shipping. Home Depot sells a Danby Kegerator built from this exact model for $800. You will be able to save about $400 building your own Kegerator. There are other Danby models which have an inner freezer that drops down vertically from the top of the mini-fridge which cannot be disconnected. You will need the model that has the freezer component attached to the back wall of the mini-fridge (see photos below). After reading several Danby "how-to" conversion instructions before that were based off of the older Danby 440BL which is not in production anymore, I thought that a newer procedure needed to written. The newer version of this model is easier to convert than the earlier versions (of course you should check your model against the photos below to make sure).