rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

Sort of a mess inside. Here are a couple pictures:

Is it any best placment of temperature probes? Where is your HERMS probe?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

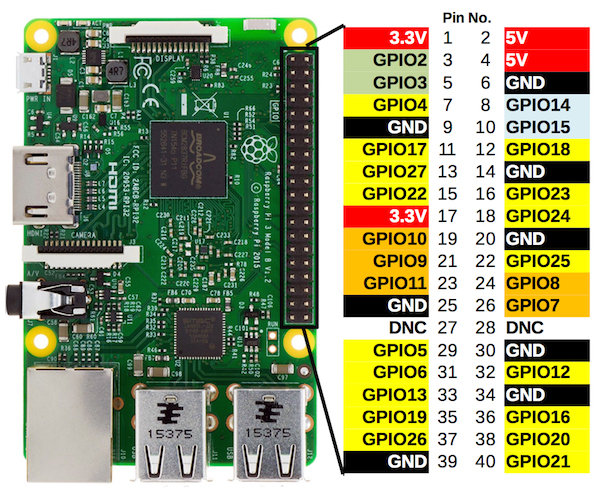

Does anyone know of a plugin for using a TRIAC (phase control)? Essentially I need to use one pin as an input from an optoisolator (this tells the Pi when the AC sinusoid is above or below a threshold voltage (so for me in the US it sends pulses at 120Hz). After seeing a pulse the Pi outputs high on a different pin (opening the TRIAC), and then goes low after a delay determined by the PID. Here's an example circuit and Arduino code: https://playground.arduino.cc/Main/ACPhaseControl/

I haven't really messed with programming things with the GPIO on the pi before, so I'm a little intimidated. But there's already something like this to work off of I think I could adapt it to my needs easily enough.

In case anyone is wondering, I prefer this over a SSR because it provides more precise/stable control. The end goal is to use cbp to control my buddy's reflux still so we need to be able to precisely adjust the power to the heat element without worrying about variation because the Pi controller isn't synched to the line frequency. That and for < $5 I can switch 20A.

I think the set up you describe would be less reliable then using PWM output, with a raspberry pi in the equation. I think you'd be better to use an SSVR and rig up a digital potentiometer to the pi, these work via phase angle.

The time response in the RPi OS will lag too mutch for a application like that. I would resort to an Arduino doing the timing and communicating with the Pi via serial or PWM.

That kind of power regulation cause a lot of rf noise, I will prefer a whole cicle control. Use a slow pwm ( 1 or 2 sec period ) and fire with a zero cross optocuppler and you are done.My first time seeing the name SSVR, but from few minutes of googling it looks like that's what I have (just built from discreet components). That's a good idea about using a digital pot, that hadn't occurred to me before. It would definitely simplify things for me.

Seems like you're in agreement. So I gather that I might have overestimated the Pi's GPIO capabilities? I haven't really looked at the specs at any length.

Although the real time response isn't really all that important. Just so long as the ON pulses fire at 60Hz and there's a timer that can measure delay, it doesn't really matter if there's a delay of a few cycles between the input trigger and the output.

Maybe I'm misunderstanding the constraint?

Totally. If you can be convinced to not use phase control, I can't think of an instance when this wouldn't give you sufficient precision in output. Much easier/cheaper to implement, and without all the noise.That kind of power regulation cause a lot of rf noise, I will prefer a whole cicle control. Use a slow pwm ( 1 or 2 sec period ) and fire with a zero cross optocuppler and you are done.

That kind of power regulation cause a lot of rf noise, I will prefer a whole cicle control. Use a slow pwm ( 1 or 2 sec period ) and fire with a zero cross optocuppler and you are done.

Can you describe the set up you're using in a bit more detail? I've done tests where pulsing isn't noticeable until like 4-5 second period lengths (e.g. visible oscillation in boil vigour). There is quite a bit of thermal inertia to most heating elements that are used for these applications that the effective output should be quite consistent with a 2 second period length. If you couldn't get reasonable temperature control doing this in the past I would think there's a problem, but would expect this related to PID tuning or programming or hardware, rather than the idea being flawed in general. A mechanical relay wouldn't be very reliable in this set up and may have been a factor for you.1-2s period is too long. I've tried it before when I was just testing with a mechanical relay, it caused noticeable fluctuations and prevented anything close to steady state operation (which is important for my application).

So I gather that I might have overestimated the Pi's GPIO capabilities? I haven't really looked at the specs at any length.

All things considered, i've finished the design for my version of the hat. feedback is appreciated before i send it to print.

View attachment 371519

All things considered, i've finished the design for my version of the hat. feedback is appreciated before i send it to print.

View attachment 371519

You can set the buzzer GPIO assignment from within settings, just like changing from Celsius to Fahrenheit. Mine is on GPIO 5.Does anyone know what GPIO pin the Terragady board uses for the buzzer?

You can set the buzzer GPIO assignment from within settings, just like changing from Celsius to Fahrenheit. Mine is on GPIO 5.

I see what you're saying now - you're probably using a Terragady 5.0 board then.Is it not assigned to a fixed gpio in the terragady board?

I see what you're saying now - you're probably using a Terragady 5.0 board then.

I'm using a 4.2 board, which doesn't have a buzzer built in. My buzzer is running directly off the Raspberry Pi.

I'm sorry, but I don't know the answer to your question since you're using a different board.

So the application is reflux distillation. The column is open to the environment for safety purposes. At steady state operation any heat fluctuations produce excess vapor which is vented off as waste. This is because there isn't a reasonable way to modulate the cooling performed by the reflux coil with such a fine grain control. There will always be some venting (or else negative pressure in the final condenser stage which is also undesirable) but it can be reduced to the degree that heat fluctuations can be reduced.Can you describe the set up you're using in a bit more detail? I've done tests where pulsing isn't noticeable until like 4-5 second period lengths (e.g. visible oscillation in boil vigour). There is quite a bit of thermal inertia to most heating elements that are used for these applications that the effective output should be quite consistent with a 2 second period length. If you couldn't get reasonable temperature control doing this in the past I would think there's a problem, but would expect this related to PID tuning or programming or hardware, rather than the idea being flawed in general. A mechanical relay wouldn't be very reliable in this set up and may have been a factor for you.

Have you confirmed you have an internet connection? It's hosted on github - which is up, and the current YAML on there is valid.New issue popped up today. I haven't booted CBP3 in a few weeks, and as of yesterday when I do, and I go to the addons page in the web gui nothing shows up anymore. Any ideaswhat might have happened?

I have CBP 3.0 setup and I am using RTD PT100 thermometers as they are part of the SSBrewtech kettles I have.

I get valid temps when one sensor is connected. When I connect the second sensor the temps appear to somewhat average. My mash tun was at 168 and I plugged in my boil kettle sensor and the MT temp dropped to 146 F and the BK showed 30 deg F higher then the water temp.

Does anyone have an idea as to what would cause this. They work fine when plugged in separately.

Thanks

TR

Do you have the sensors hooked up separately? Are those resistance based sensors? They would each need to be on their own GPIO.

They both use web servers as the interface, so you'll need to make sure their servers are running on different ports (port 80 is standard for web servers - at least one of them will need to be moved to a different port), or you will need to do some web server configuration to put them on different directories under the root of the webserver.I just did an install of CBPi on RPi 3 Buster. I cant access the GUI, is this because I also have RasperryPints installed? I'm probably doing something dumb, brand new to RPi. Thanks.

My first time seeing the name SSVR, but from few minutes of googling it looks like that's what I have (just built from discreet components). That's a good idea about using a digital pot, that hadn't occurred to me before. It would definitely simplify things for me.

There's an alternative, which is a 0-5V controlled SSVR that's controlled by a control voltage instead of a pot. Auber sell a 25A one which should be capable of controlling 4500W element on 240V (or maybe just about a 5500W one - Auber says that their SSVR should be derated to 90-95%, with a 5500W element coming in at 92%). You can also find these from AliExpress and eBay, with the usual strong note of caution for SSR/SSVRs from these sources.

The response of the Auber SSVR isn't very linear, with most of the variation in power level coming in the 2-3 V control signal range, so you'll need a reasonably high bit-count DAC output to give fine grained control, or a bit of analog circuitry to reduce the effective range. An 8-bit DAC should give about 50-60 effective power levels, while a 12-bit one would give closer to 800 different levels. With a 12-bit DAC, you could linearize the output in software.

Adafruit will sell you a single or quad channel I²C 12-bit DAC breakout board for not much. I've just ordered the Auber SSVR to eventually get around to playing with.

If I remember right Buster come with Python 3 by default.I just did an install of CBPi on RPi 3 Buster. I cant access the GUI, is this because I also have RasperryPints installed? I'm probably doing something dumb, brand new to RPi. Thanks.

Whew read threw all 42 pages, this project has certainly been a journey!

The 40A SSRs that the majority of us use require 7mA - 20mA. The GPIOs on Pis are rated for 18mA, but combined on the 3.3V rail is 50mA.

I haven't started playing yet, but I'm definitely curious if anyone has had long-term success with their Pi directly driving their brewery without using transistors in some fashion between the gpio and control relaysOn paper it seems unlikely