I'm not sure what other people are doing, but 1-2 minutes sounds like overkill to me. It's not so much it being slow, as it is being consistent (with obvious exceptions, doing it consistently in .5 seconds wont work as well). If you open as a constant rate, then bed will set nicely. If you end up jerking or uneven opening of the valve the bed is sort of rushed and can cause stuck sparges. In any case, open the valve about 1/4 during vorlauf, and by the time you find there is no more grain coming out, the bed is probably set (AKA you can open the valve the whole way, just don't do it in one snappy motion).

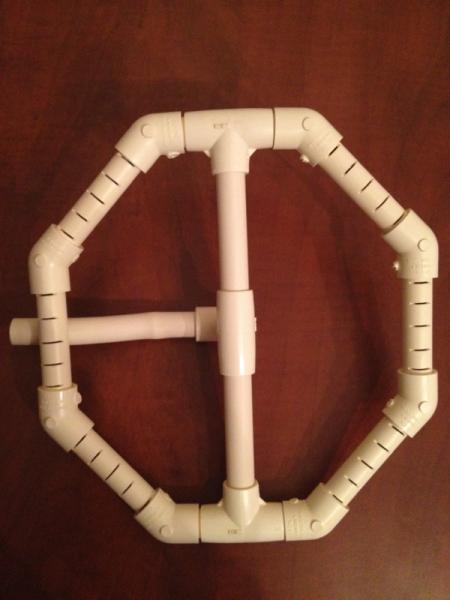

I agree with gluing the 'dip tube' portion of the manifold, but the slotted horizontal pieces should be left together as you said. I recommend that next time you are brewing, add all of the sparge water at slightly above strike temp. Leave it in there for a minute or so, then inspect the manifold before dumping in the grain. If all of the connections look tight, then hopefully you're good. If the same problem persists, it must be that you're hitting the manifold while doughing in. This is what I'll try for my next batch, hopefully it works!

I agree with gluing the 'dip tube' portion of the manifold, but the slotted horizontal pieces should be left together as you said. I recommend that next time you are brewing, add all of the sparge water at slightly above strike temp. Leave it in there for a minute or so, then inspect the manifold before dumping in the grain. If all of the connections look tight, then hopefully you're good. If the same problem persists, it must be that you're hitting the manifold while doughing in. This is what I'll try for my next batch, hopefully it works!