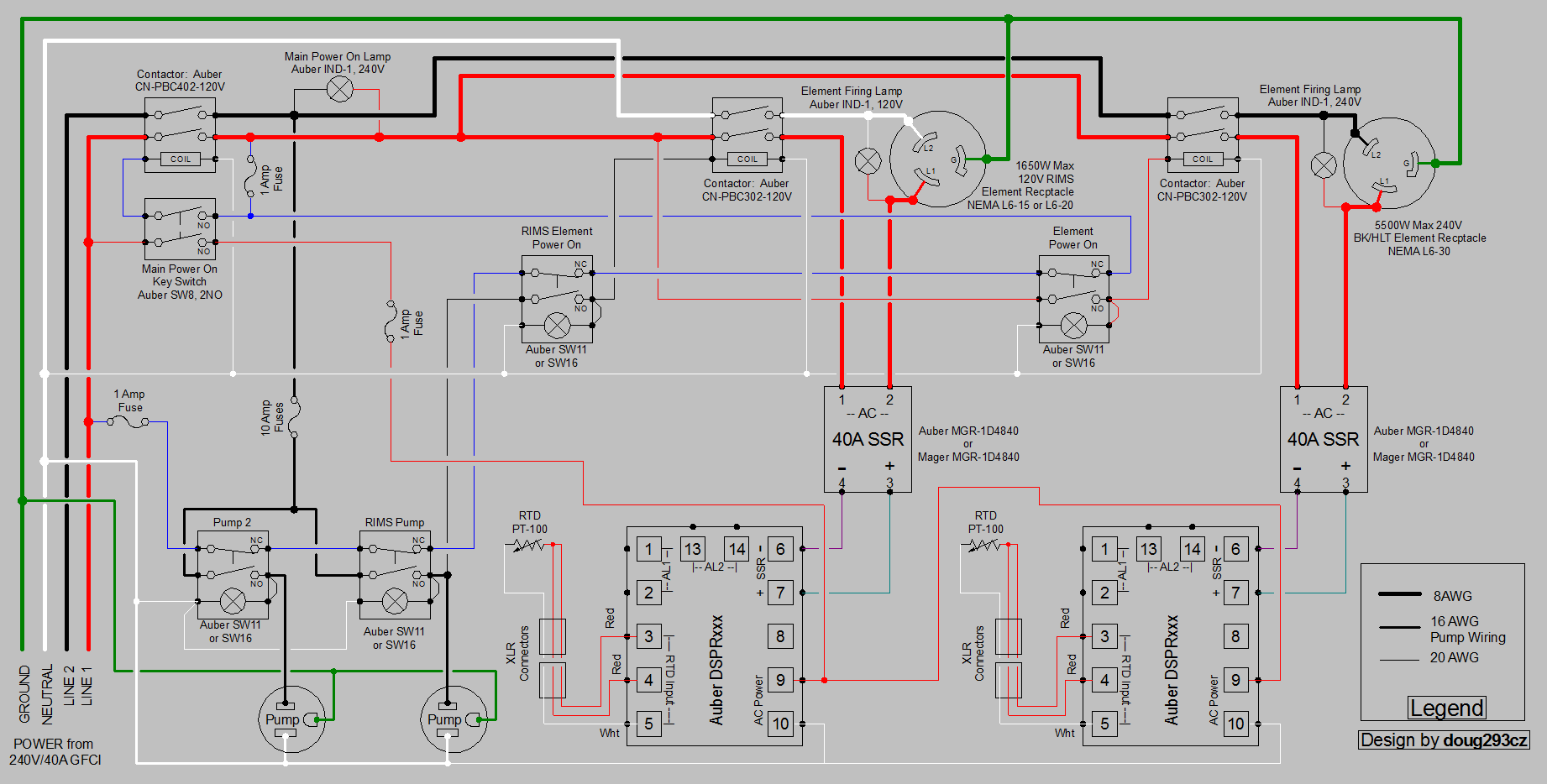

Yes, this will work. The Brewhardware.com 1650 foldback element is listed as ULWD, so should be fine. The plugs/receptacles don't care what voltage they are actually carrying, so yes, you can use a L6-30 for the 120V element. Just make sure not to swap your cables between elements, as you will fry the 1650W element if you hook it up to the 5500W element cable. If you run your pump(s) from the hot line not used for the 120V element, then the pumps will not increase your total current draw at all (they will just shift current from the neutral to the hot line they are on)So if I go with 40A, running a 5500W element for BK and get a 1650 120v element, I'm at about 37A. Plus less than 2A for the pump because I'll only be running one pump for awhile. I should be fine then right? Should I be looking for a low density watt element for the RIMS tube? Can you run a 120V low watt element off a 240V plug?

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)