No, I didn't, but I might get to it tonight.

Sweet. I'm such a noob at this, something tells me I'll be happy I waited

No, I didn't, but I might get to it tonight.

Land o Lincoln, you might want to take down your first drawing where you're switching the white wire. It's a pretty big safety hazard to switch the neutral!

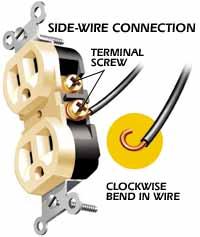

Also, in the second drawing, you don't need the wire if you leave the tab on the white side of the receptacle. If you've broken the tab you can just put a wire between the screws and be fine.

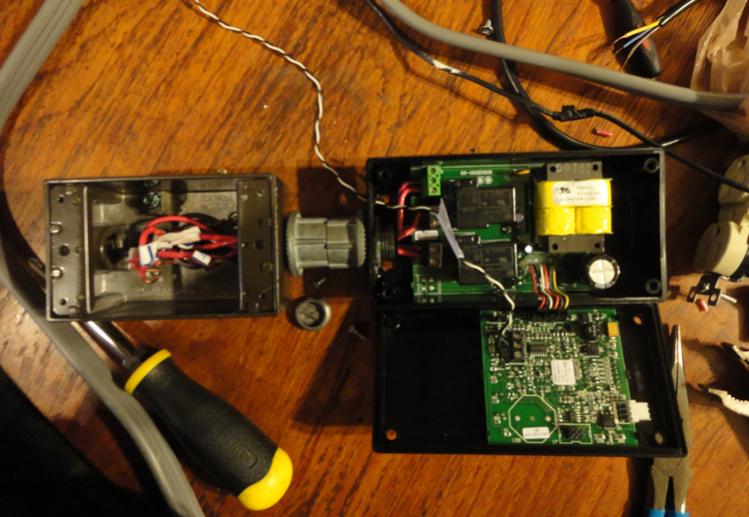

And that should do it. Tested it out with the outlet tester and the wiring checks out. Good job, me. And thanks to everybody else that told me how I did it wrong.

This is a nice controller. I'm glad I got it.

So you switched the power leg around? Did this new setup take care of your "open neutral" issue?

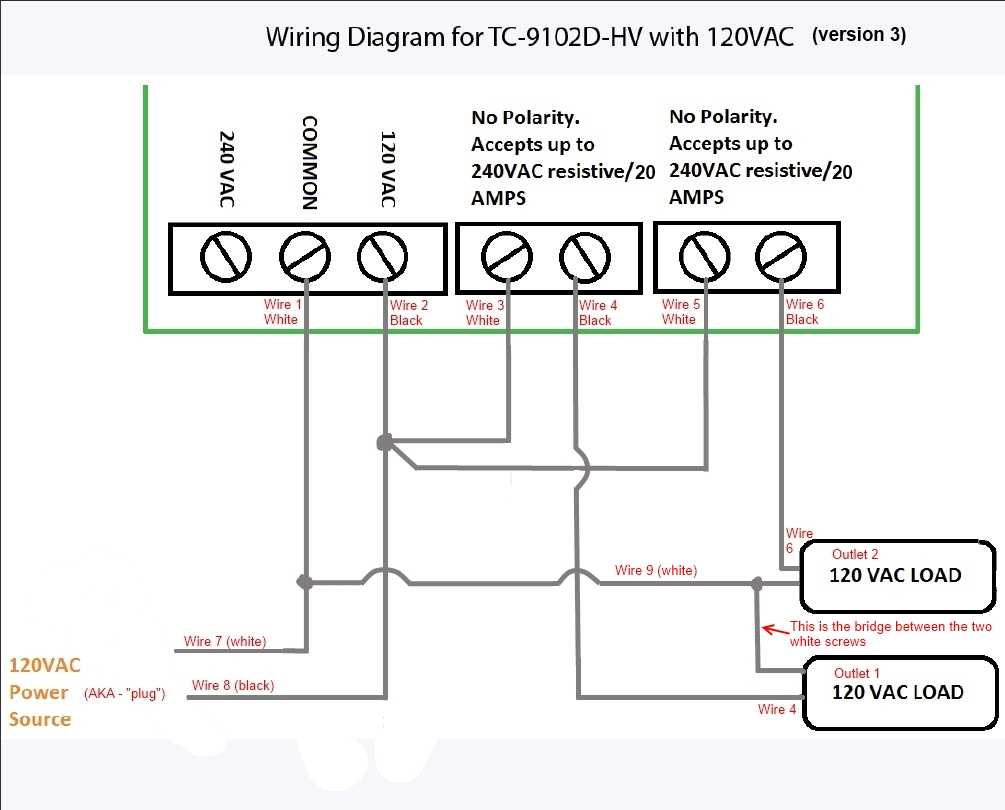

I'm considering getting one of these but I'm a total noob at dealing with electrical wiring. I was looking at the manufacturer's website and was wondering why you guys didn't mimic their diagram. http://www.protectedhome.com/documents/TC9102DHV 120 VAC Wiring Diagram.pdf

Any other help is appreciated. I'd like to get this one, but I keep wavering because I'm not confident with electricity. It kills!

I've wired one of these up and want to configure it to keep a fridge at a set temp.

I've successfully turned off relay2 which I won't be using, but I could really use some help figuring out how Set Point1, High Set Point1, Low Set Point1 work.

I can set the values but I don't understand how they work together.

Could someone post an example to help get me started?

To keep the fridge at 45 degrees:

SP1 = ___

HSP1 = ___

LSP1 = ___

Thanks!

bad coffee said:That is wrong, and totally unsafe.

You never want to leave the 'hot' wire on all the time. The hot wire should be switched by the relay.

If you wired yours with the hot on all the time you should rewire it correctly.

B

Just bought two of these for two 14.8 cf freezers for my garage here in the Chicago area. I work with electrical all the time in my decorating business so i have outlets, boxes, 14 & 12 solid wire, caps and all lying around so this looks like a no brainer to me. Most important is everyone seems quite happy with the results after its assembled.

Whats the best option for the heating element? I assume 14 gauge wire is good for the heater if its only a 4 foot run. Just drop it in the back hinge side between the weather strip like the thermometer?