You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Constant Battle - Ethyl Acetate - Looking for suggestions.

- Thread starter Christophrawr

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

RPh_Guy

Bringing Sour Back

You're thinking of isoamyl acetate?Ethyl acetate (banana flavor)

@Christophrawr

I always have microbes on the brain but as mentioned, contamination does sound possible. Consider trying a new cleaning agent, heat-sanitizing what you can, and switching out some of the plastic/rubber parts. Break apart everything when cleaning, especially valves.

Even if this doesn't fix it, you'll have cleaner equipment and some backup parts.

I would also invest in a bottling wand to [slightly] reduce aeration when bottling.

Best of luck!

Christophrawr

Well-Known Member

I use velcro to hold bubble wrap tight to the carboy and wedge the probe between the two.

I could try a new cleaner. Right now Im scrubbing (soft sponge) with soap, good rinse, oxyclean whatever needs a better clean (blow off tubes and carboys) then star san before using again. Maybe iodophor? I can also look into a heat blast. Do you do this cleaning morning of brew day or after when putting everything away?

I have a bottling wand, Ill give it a shot again and put it on my list of "to try"

I could try a new cleaner. Right now Im scrubbing (soft sponge) with soap, good rinse, oxyclean whatever needs a better clean (blow off tubes and carboys) then star san before using again. Maybe iodophor? I can also look into a heat blast. Do you do this cleaning morning of brew day or after when putting everything away?

I have a bottling wand, Ill give it a shot again and put it on my list of "to try"

I've followed this and there are several things OP should do, IMO.

1. Have someone else taste the beer. Perhaps bring a bottle to a local brewery and ask them for an opinion. Do not tell them what you're looking for. See if anyone else can pick up this off-flavor.

2. Find an experienced local homebrewer and have them walk you through, or watch you do, a brew day. Such a person could also comment on the beer.

3. Get a couple gallons of distilled or RO water from the store and use that instead of your tap water. I suspect the tap water is a big part of this if in fact it's not confirmation bias. Since you're using BrunWater there should be no particular problems getting the water right.

Until you've done most of the above, the rest of this is just speculation; it's time to confirm or refute some of the above and move from there.

Good luck!

1. Have someone else taste the beer. Perhaps bring a bottle to a local brewery and ask them for an opinion. Do not tell them what you're looking for. See if anyone else can pick up this off-flavor.

2. Find an experienced local homebrewer and have them walk you through, or watch you do, a brew day. Such a person could also comment on the beer.

3. Get a couple gallons of distilled or RO water from the store and use that instead of your tap water. I suspect the tap water is a big part of this if in fact it's not confirmation bias. Since you're using BrunWater there should be no particular problems getting the water right.

Until you've done most of the above, the rest of this is just speculation; it's time to confirm or refute some of the above and move from there.

Good luck!

Christophrawr

Well-Known Member

I'll be brewing Sunday morning and will be trying a few of the things mentioned. I'll report back with what I did differently and if the flavor persists. Ill also ask the one homebrewer going pro I know to taste a bottle after [emoji4] so Ill repost in a few weeks.I've followed this and there are several things OP should do, IMO.

1. Have someone else taste the beer. Perhaps bring a bottle to a local brewery and ask them for an opinion. Do not tell them what you're looking for. See if anyone else can pick up this off-flavor.

2. Find an experienced local homebrewer and have them walk you through, or watch you do, a brew day. Such a person could also comment on the beer.

3. Get a couple gallons of distilled or RO water from the store and use that instead of your tap water. I suspect the tap water is a big part of this if in fact it's not confirmation bias. Since you're using BrunWater there should be no particular problems getting the water right.

Until you've done most of the above, the rest of this is just speculation; it's time to confirm or refute some of the above and move from there.

Good luck!

Thanks again everyone. Talk soon.

You're thinking of isoamyl acetate?

Good catch although one of the sources I found did describe ethyl acetate as having the banana aroma and another called it sweetly fruity. I would guess that some people could easily mis-identify it as banana as our noses don't all work the same.

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

My 2 cents: You say you are pouring from the spigot down the side of the bottle. Oxidation could be part of the issue - get a bottling wand.

I wonder how much your cleaning of the bottles etc, is leaving residue on the bottles. I just rinse the bottles after use. Sight them to see that there is no visible crud left, then store them. On bottling day, I will rinse them if they have dust on them, otherwise I use a Vinator to squirt Starsan into the bottles. Several pumps then they go on the dishwasher rack. I sanitize 56+ bottles for my 5 gallon batches all at one time. I have had 1 infected bottle in 7 1/2 years.

You are mixing the Starsan to the proper strength? 1 ounce of Starsan in 5 gallons of water?

I wonder how much your cleaning of the bottles etc, is leaving residue on the bottles. I just rinse the bottles after use. Sight them to see that there is no visible crud left, then store them. On bottling day, I will rinse them if they have dust on them, otherwise I use a Vinator to squirt Starsan into the bottles. Several pumps then they go on the dishwasher rack. I sanitize 56+ bottles for my 5 gallon batches all at one time. I have had 1 infected bottle in 7 1/2 years.

You are mixing the Starsan to the proper strength? 1 ounce of Starsan in 5 gallons of water?

Christophrawr

Well-Known Member

Literally just lost a piece of my bottling wand down the sink 10 minutes ago. Ouff.My 2 cents: You say you are pouring from the spigot down the side of the bottle. Oxidation could be part of the issue - get a bottling wand.

I wonder how much your cleaning of the bottles etc, is leaving residue on the bottles. I just rinse the bottles after use. Sight them to see that there is no visible crud left, then store them. On bottling day, I will rinse them if they have dust on them, otherwise I use a Vinator to squirt Starsan into the bottles. Several pumps then they go on the dishwasher rack. I sanitize 56+ bottles for my 5 gallon batches all at one time. I have had 1 infected bottle in 7 1/2 years.

You are mixing the Starsan to the proper strength? 1 ounce of Starsan in 5 gallons of water?

Ill get a new one but for bottling this weekend Ill use a tube with a clamp as a substitute.

Im mixing 1/4 oz in about 2-2.5 gallons of water. Up my dose? But now Im thinking about soaking in oxyclean morning of brewday then rinsing and spraying with star san bottle. Thoughts on that?

Yeah probably going overboard with the bottles. I can probably skip the bleach and just oxyclean or rinse then store... Its hard to make things simpler Im finding.. my brain..

Literally just lost a piece of my bottling wand down the sink 10 minutes ago. Ouff.

Ill get a new one but for bottling this weekend Ill use a tube with a clamp as a substitute.

Im mixing 1/4 oz in about 2-2.5 gallons of water. Up my dose? But now Im thinking about soaking in oxyclean morning of brewday then rinsing and spraying with star san bottle. Thoughts on that?

Yeah probably going overboard with the bottles. I can probably skip the bleach and just oxyclean or rinse then store... Its hard to make things simpler Im finding.. my brain..

Lose the bleach entirely. There's no upside.

Know how I clean my bottles? Triple-rinse when first emptied, then I put 'em in the dishwasher. They're sanitized with Star-San just prior to bottling.

Why are you using oxyclean on brew day? You said you clean everything after you brew right? Just use starsan on brew day. No need to clean what’s already clean. Probably not going to help with the flavor but is an unnecessary step.

I’d hone in on ferm temps. What do you use for a ferm chamber. What do you use as a temp controller? What do you use for a temp probe? When was the last time you calibrated, or at least verified, the accuracy of the temp probe?

I’d hone in on ferm temps. What do you use for a ferm chamber. What do you use as a temp controller? What do you use for a temp probe? When was the last time you calibrated, or at least verified, the accuracy of the temp probe?

Ditto on getting a second (third, etc., if need be) tasting opinion of your beer. Don't tell them anything, let the tasting be as unbiased as possible. Just, "what do you think of this IPA?" Sometimes, once you taste an off-flavor you think it's always there. Confirmation bias. You acquire a perception, that perception is like a hammer and everything starts looking like a nail. I once had a bad diacetyl problem in a batch, so bad I poured it out. Several brews after that I could have sworn diacetyl was in those too, despite being told by others they didn't taste it.

Ditch the chlorine bleach. You just can't get the smell and taste of it out and minute traces of it can form off-flavor compounds in the beer. Starsan provides excellent sanitation if the gear is clean first.

Ditch the chlorine bleach. You just can't get the smell and taste of it out and minute traces of it can form off-flavor compounds in the beer. Starsan provides excellent sanitation if the gear is clean first.

Christophrawr

Well-Known Member

Hi!!Why are you using oxyclean on brew day? You said you clean everything after you brew right? Just use starsan on brew day. No need to clean what’s already clean. Probably not going to help with the flavor but is an unnecessary step.

I’d hone in on ferm temps. What do you use for a ferm chamber. What do you use as a temp controller? What do you use for a temp probe? When was the last time you calibrated, or at least verified, the accuracy of the temp probe?

You read the OP right - I only do oxyclean on stuff after its used before putting it in to storage. I was just wondering if I should be cleaning again before immediately using or if just tossing everything into star san was ok (like Im doing now)

I use a mini fridge with an inkbird controller. Temps are bang on for the probe. If i chill my wort to 66 and pitch yeast then put it in the chamber the probe reads 66 right away.

Maybe I can try holding at 64F for US05. One response brought up using different temps per yeast which makes sense but I assumed going 66 across the board would be just fine (ramping up saisons after a few days)

Christophrawr

Well-Known Member

I dont have a dishwasher and unfortunately my sinks dont have the screw end for bottle washers. The pressure blasts the thing off the sink reaallll dramatically. So I give my bottles big rinses. Then the oxyclean then bleach. Ill drop the bleach!Lose the bleach entirely. There's no upside.

Know how I clean my bottles? Triple-rinse when first emptied, then I put 'em in the dishwasher. They're sanitized with Star-San just prior to bottling.

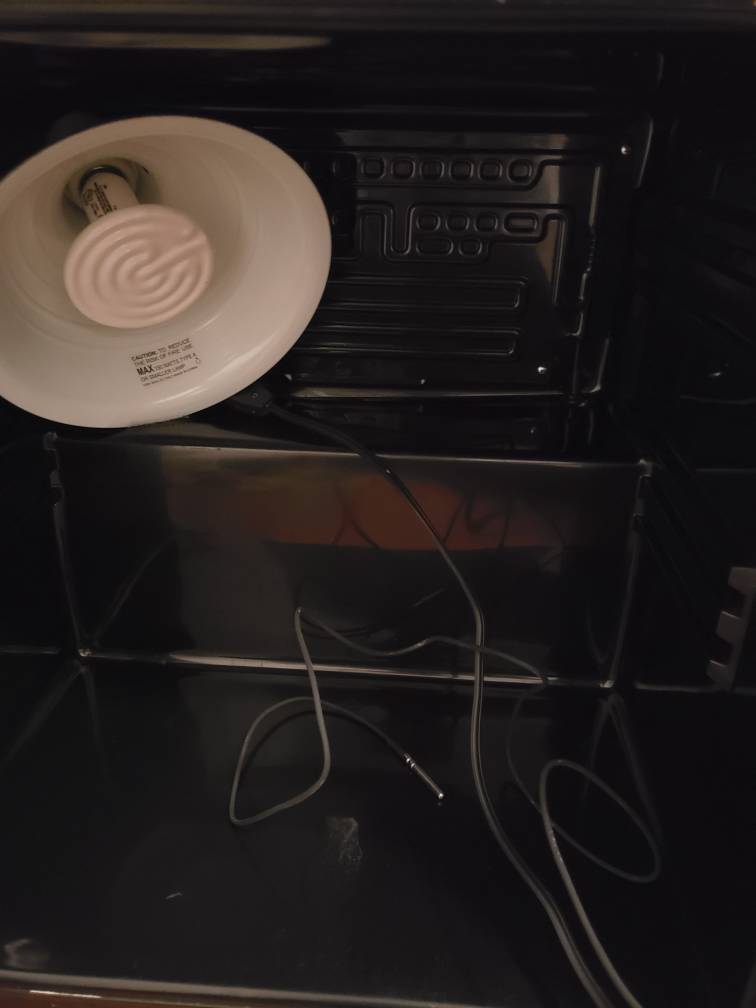

View attachment 599278

I second (or third, or whatever) the suggestion that you use distilled or RO water and then salt to taste w/ Bru'n Water.

Christophrawr

Well-Known Member

That should probably be the first thing i try hey. There's a pharmacy near by that sells distilled in bigger bottles. I'll actually do that tomorrow when i brew. Thanks.I second (or third, or whatever) the suggestion that you use distilled or RO water and then salt to taste w/ Bru'n Water.

Christophrawr

Well-Known Member

Will using distilled water mean less reason to use campden tablets? Or the benefit of the tablets makes them always good to use regardless?

Will using distilled water mean less reason to use campden tablets? Or the benefit of the tablets makes them always good to use regardless?

The reason people use them is to counteract any chlorine or chloramine in the water. If there's none, then no need, unless you're doing LODO brewing, which you're not.

Ditch the chlorine bleach. You just can't get the smell and taste of it out and minute traces of it can form off-flavor compounds in the beer

I don't normally use bleach, but once I bleach soaked my bottles (four cases) cleaning up after an infection. I rinsed with hot tap water using a jet bottle washer, and never got any chlorophenol taste. So it seems to me you can rinse the bleach out of glass bottles successfully. If I'm wrong, I'll have a problem because I'm now in the process of giving them another bleach soak as a preventive measure.

I dont have a dishwasher and unfortunately my sinks dont have the screw end for bottle washers. The pressure blasts the thing off the sink reaallll dramatically. So I give my bottles big rinses. Then the oxyclean then bleach. Ill drop the bleach!

I you would like to use a bottle washer, there's an adapter you can screw onto the faucet: https://www.williamsbrewing.com/Hose-Thread-Faucet-Adapter-P154.aspx

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

Isoamyl Acetate and Ethyl Acetate does not taste the same. TS says that he has excessive amounts of Ethyl Acetate, it might be wrong but that's what we have. Nail Polish-y. Lacto sours the beer and doesn't get nail-polish-y. I've had a few lacto infections which were "good", but excessive ethyl acetate is horrible. It's either a strange infection, or something in the water/cleaning agent, which causes it, is still my guess. Lacto infection is often not that bad, other than it get's sour over time.

Christophrawr

Well-Known Member

Just bottled a batch and had the same nail polish like chemical scent/taste. So that's before bottling. Less worried about oxidation during bottling nowhere and looking more at my sanitation, temp probe accuracy (will test it this week) and my water. Will continue following up.

I also detected a faint ethyl acetate on my last batch. I used US-05 and the yeast had started to clear, but I didn’t want to wait too long because it’s an IIPA and I don’t want the hops to fade. Immediately after bottling the yeast dropped clear within 24 hours. I had to move the bottles around to allow the sediment to settle off the ledges in my redhook bottles. I put my tester bottle in the fridge after two weeks of conditioning and there was some chill haze. I drank it before the haze dropped and it was excellent. I was on the lookout for ethyl acetate and didn’t detect it at all. In fact the beer was delicious and my wife thought so too. I keep talking about my next brew and she says that she keeps thinking about this brew. I’ll chill the remaining eighteen bottles next week and after the chill haze drops in about 4 days, the beer will be fair game. Anyway, maybe try packaging the beer and give it some time. Ethyl acetate is one of those flavors that is created by yeast and also one that perhaps people are talking about the yeast “cleaning up”. You may be particularly sensitive to this flavor, so giving the yeast the proper time to clean up or picking a yeast that produces less of this may help you.

Christophrawr

Well-Known Member

Update for all you rad people.

I took a sample of a pale ale fermented with US05 last night that I brewed 8 days ago - picked up minute traces of the off flavor again. I immediately went to test my probe since it's on my to-try list we've created.

I found my probe is accurate when holding it next to my digital thermometer or taping both to the side of a heated up mason jar of water, within 1F at least. But then I stuck my digital in to the water and left my probe against the glass; I had a 5F difference. I tested this multiple times with the same result.

I asked when I first built my chamber if I should set my controller to a lower setting knowing that the carboys internal heat would be 5-8F warmer. The general response I got was the probe should be accurate enough taped to the side.

What are you thoughts on this and do you think this small trace of solvent could be coming from US05 fermenting at a true temp of 70-72F instead of the 66 I thought I was at?

I got my campden tablets today so I'll give them a try this weekend and set my controller to 61F during the active fermentation?

I took a sample of a pale ale fermented with US05 last night that I brewed 8 days ago - picked up minute traces of the off flavor again. I immediately went to test my probe since it's on my to-try list we've created.

I found my probe is accurate when holding it next to my digital thermometer or taping both to the side of a heated up mason jar of water, within 1F at least. But then I stuck my digital in to the water and left my probe against the glass; I had a 5F difference. I tested this multiple times with the same result.

I asked when I first built my chamber if I should set my controller to a lower setting knowing that the carboys internal heat would be 5-8F warmer. The general response I got was the probe should be accurate enough taped to the side.

What are you thoughts on this and do you think this small trace of solvent could be coming from US05 fermenting at a true temp of 70-72F instead of the 66 I thought I was at?

I got my campden tablets today so I'll give them a try this weekend and set my controller to 61F during the active fermentation?

- Joined

- May 28, 2018

- Messages

- 3,262

- Reaction score

- 2,971

Is this an off flavor in otherwise drinkable beer, or so bad they are dumpers?

I had a very tough infection that persisted for a while, and was only cured after full take down of every valve, baking at 400F what I could, long boil on the rest, and replacement of all process tubing.

What I had was not an off flavor however, it tasted practically toxic, and ruined my pallet for a couple days if I did taste.

I had a very tough infection that persisted for a while, and was only cured after full take down of every valve, baking at 400F what I could, long boil on the rest, and replacement of all process tubing.

What I had was not an off flavor however, it tasted practically toxic, and ruined my pallet for a couple days if I did taste.

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

Update for all you rad people.

I took a sample of a pale ale fermented with US05 last night that I brewed 8 days ago - picked up minute traces of the off flavor again. I immediately went to test my probe since it's on my to-try list we've created.

I found my probe is accurate when holding it next to my digital thermometer or taping both to the side of a heated up mason jar of water, within 1F at least. But then I stuck my digital in to the water and left my probe against the glass; I had a 5F difference. I tested this multiple times with the same result.

I asked when I first built my chamber if I should set my controller to a lower setting knowing that the carboys internal heat would be 5-8F warmer. The general response I got was the probe should be accurate enough taped to the side.

What are you thoughts on this and do you think this small trace of solvent could be coming from US05 fermenting at a true temp of 70-72F instead of the 66 I thought I was at?

I got my campden tablets today so I'll give them a try this weekend and set my controller to 61F during the active fermentation?

Us-05 does not throw off a lot of ehtyl acetate. I use it quite often and sometime when I'm in a need for a beer quickly I start at 16C and ramp it with 0.25C pr hour meaning I'm at 28C in 48 hours. But I do overpitch.

Christophrawr

Well-Known Member

But it can produce small traces? Because I'm pitching at 20c ish and then its going straight to 22F in the chamber when I think it's lower. Maybe hitting the wort at 20c isn't helping. Keep in mind I'm not expert on off flavors, I wonder if I'm perceiving a ripe banana as solventy (US-05 fermenting warmer) since the one time I used US-04 I didn't taste it... and with Belle Saison I get a similar off flavor which could be over ripe banana again, esters? Maybe I just @$%& hate banana esters?Us-05 does not throw off a lot of ehtyl acetate. I use it quite often and sometime when I'm in a need for a beer quickly I start at 16C and ramp it with 0.25C pr hour meaning I'm at 28C in 48 hours. But I do overpitch.

But I also have some weight still leaning on the water and look forward to how the campden tablets help / distilled water.

Regarding other reply; for the off flavor its totally drinkable, just hanging out in the background laughing at me all the time.

Last edited:

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

But it can produce small traces? Because I'm pitching at 20c ish and then its going straight to 22F in the chamber when I think it's lower. Maybe hitting the wort at 20c isn't helping. Keep in mind I'm not expert on off flavors, I wonder if I'm perceiving a ripe banana as solventy (US-05 fermenting warmer) since the one time I used US-04 I didn't taste it... and with Belle Saison I get a similar off flavor which could be over ripe banana again, esters? Maybe I just @$%& hate banana esters?

But I also have some weight still leaning on the water and look forward to how the campden tablets help / distilled water.

Regarding other reply; for the off flavor its totally drinkable, just hanging out in the background laughing at me all the time.

Us-05 does not throw off noticable isoamyl acetate either, to my palate at least. I do a lot of hefes and feel that I can pick out one banana out of a billion other things in beer. I do also get it from "clean" norwegian lagers, when other's cant, but not from us-05.

Christophrawr

Well-Known Member

Hey!! Pretty clean I'd say. Here are some picks.I am not a "Beer Troll"... this is like beer detective work.. how clean is your fermentation chamber? Put mason jar with water lid off and taste what happens..

4of7

60sqftbrewhouse

- Joined

- Apr 16, 2017

- Messages

- 549

- Reaction score

- 111

I was just thinking out side of the keg. Not trying to disrespect your cleaning.just saying something out side the norm., Your the one chasing a problem .... just put some water in there and taste it.just saying that it could be .

Similar threads

- Replies

- 19

- Views

- 2K

- Replies

- 12

- Views

- 1K

- Replies

- 3

- Views

- 568

- Replies

- 15

- Views

- 855