DPJ123

Member

- Joined

- Apr 1, 2021

- Messages

- 9

- Reaction score

- 2

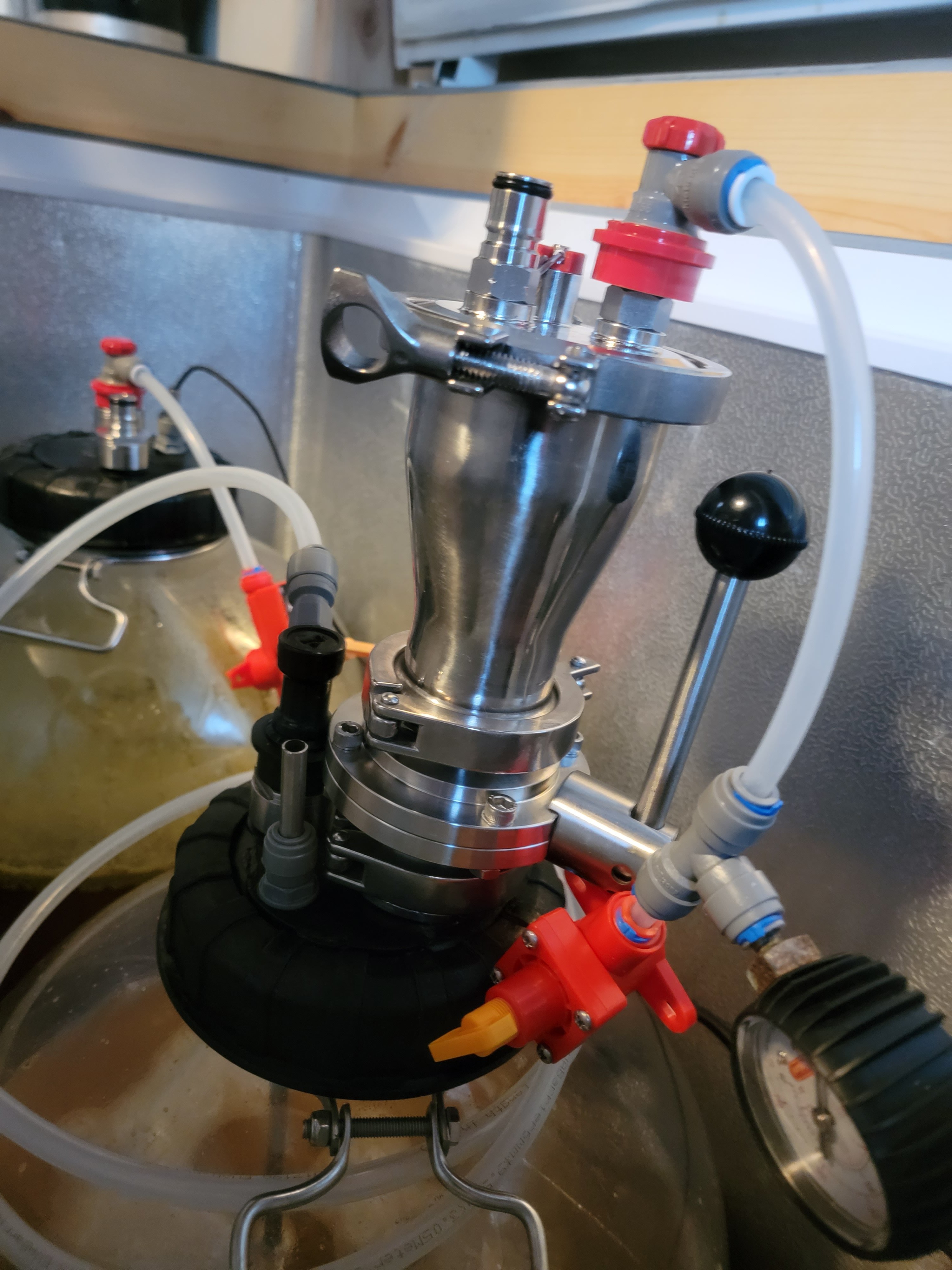

Update:

I tried out the fermzilla DH set-up today, and like schmurf's experience, it sucked. I thought if I smashed the hops a bit with a rubber mallet they'd go through just fine, but that wasn't the case. If you're doing more than an ounce you'd pretty much have to pulverize them in a food processor, which might defeat the purpose. Probably best to rock on with the magnet bag set up!

I tried out the fermzilla DH set-up today, and like schmurf's experience, it sucked. I thought if I smashed the hops a bit with a rubber mallet they'd go through just fine, but that wasn't the case. If you're doing more than an ounce you'd pretty much have to pulverize them in a food processor, which might defeat the purpose. Probably best to rock on with the magnet bag set up!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)