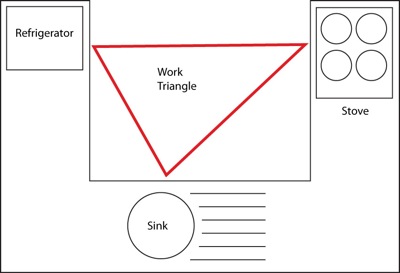

I'm going to add one more thing--I've been thinking about how I would design a brew area if I had a blank canvas with which to work. I was thinking about the

kitchen work triangle, which is an approach to design the optimal kitchen work area primarily situating the refrigerator, the stove, and the sink.

The Wiki article I linked above explains this pretty well, but the keys to it are to keep things within reasonably close distance to each other, but not too close. Here are some of them:

- No leg of the triangle should be less than 4 feet (1.2 m) or more than 9 feet (2.7 m).

- The sum of all three sides of the triangle should be between 13 feet (4.0 m) and 26 feet (7.9 m).

- Cabinets or other obstacles should not intersect any leg of the triangle by more than 12 inches (30 cm).

- If possible, there should be no major traffic flow through the triangle.

- A full-height obstacle, such as a tall cabinet, should not come between any two points of the triangle.

Besides the work triangle itself, there are several rules of thumb to consider when planning a kitchen:[3][4]

- As measured between countertops and cabinets or appliances, work aisles should be no less than 42 inches (110 cm) for one cook, or 48 inches (120 cm) for multiple cooks.

- A sink should have a clear counter area of at least 24 inches (61 cm) on one side, and at least 18 inches (46 cm) on the other side.

- A refrigerator should have a clear counter area of at least 15 inches (38 cm) on the handle side; or the same on either side of a side-by-side refrigerator; or the same area on a counter no more than 48 inches (120 cm) across from the refrigerator.

- A stove or cooktop should have a clear 15 inches (38 cm) area on one side, and at least 12 inches (30 cm) on the other side.

- At least 36 inches (91 cm) of food preparation area should be located next to the sink.

Now, this is for a kitchen, not a brew space, but I think there are some lessons to be learned here, especially since you have that blank canvas with which to work.

Suppose you had an area that was 15 x 12 feet square. Do you want the sink on one wall and the brew area on the opposite wall 15' away? I'd think not. I'd want that sink as reasonably close to the brew area as I could get it, but not too close.

I'd be working to reduce the steps needed to traverse the space, but retaining enough space so I had countertop area available, a drainboard area next to the sink, etc. etc.

If you refer to the pic below, you can see how my space is set up.

(and for those inspecting the space with a critical eye, it's a working space--I have all the stuff I've cleaned lying next to the sink, the pump is disassembled for inspection and any necessary cleaning [none needed as it turns out], and I took that pic without cleaning up the whole space first.

).

From the left side of the mash tun on the left to the wall behind the sink, it's about 8.5 feet. I could even move the kettles closer together if I needed to, but the spacing allows me to swap hoses around without having the use different hoses. The distance along the back wall of the sink to the white rolling cabinet is about 6 feet. So, my basic brewing area is 6 x 8.5 feet.

Nothing is more than about 2 steps from anything else, and most of the time, it's a step or within easy reach. Labels help with me getting things back where they belong.

If I had that blank canvas, I'd have a stainless table or base cabinet or something coming off the white cabinet on the right, behind me, so that I had a "U-shaped" space. I'd do my water addition measuring there, testing ph, my other stuff would be there. As it is, I have a small table I set up for those purposes, use the small shop stool to sit at that table and record info in my notebook, do my measuring, etc.

What this all means (as I think this through), is that I could have a very functional, very efficient, brew space in an area that would be maybe 8 x 9 feet, maybe 8 x 8.

Here's the wide angle pic of the whole area:

Here's a closeup showing things I've figured out over time that make the space more efficient for me.

A: I have a bunch of little tip-forward bins I store parts in. Got them free from Menards on some sort of rebate thing, but they're perfect for everything from silicone gaskets to posts to end caps to...everything.

B: Same bins. The microwave, which I use to boil water to sanitize my oxygenating wand, has to sit exactly where it is due to the brackets holding the shelves. So some bins on one side, some on the other.

C: I even mounted some on the wall next to the pegboard. I've got some spare quick disconnects in one of them, some gelatin packets I use when making finings, etc. Nice thing about these bins is even if labeled as some are, I can see what's in them.

D: Hard to show well here, but there are two aluminum....prongs that I made attached to the underside of the shelves. That's where I store my hydrometers, long thermometers, poor-man's bottle filling attachment. Up and out of the way, but easily accessible.

E: Everybody needs a paper-towel dispenser handy, right?

F: (on the bottom), the rolling cabinet on the right; it functions the same as if I had counter space to the right of the sink.

If I had that blank canvas, I wouldn't go any wider than about 8 feet, and I wouldn't go any deeper than about 8 feet.

Further, I'd start with the placement of the sink--since that often is predetermined by drains and pipes and such--and build out from there. The other issue would be dealing with steam. Vent hood? Steam slayer? That is the other main issue.

Anyway, enough blathering. This should give you some things to think on w/r/t how and where you place things, AND how many steps you want to take to move around the brew area. For me, I want fewer steps.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)