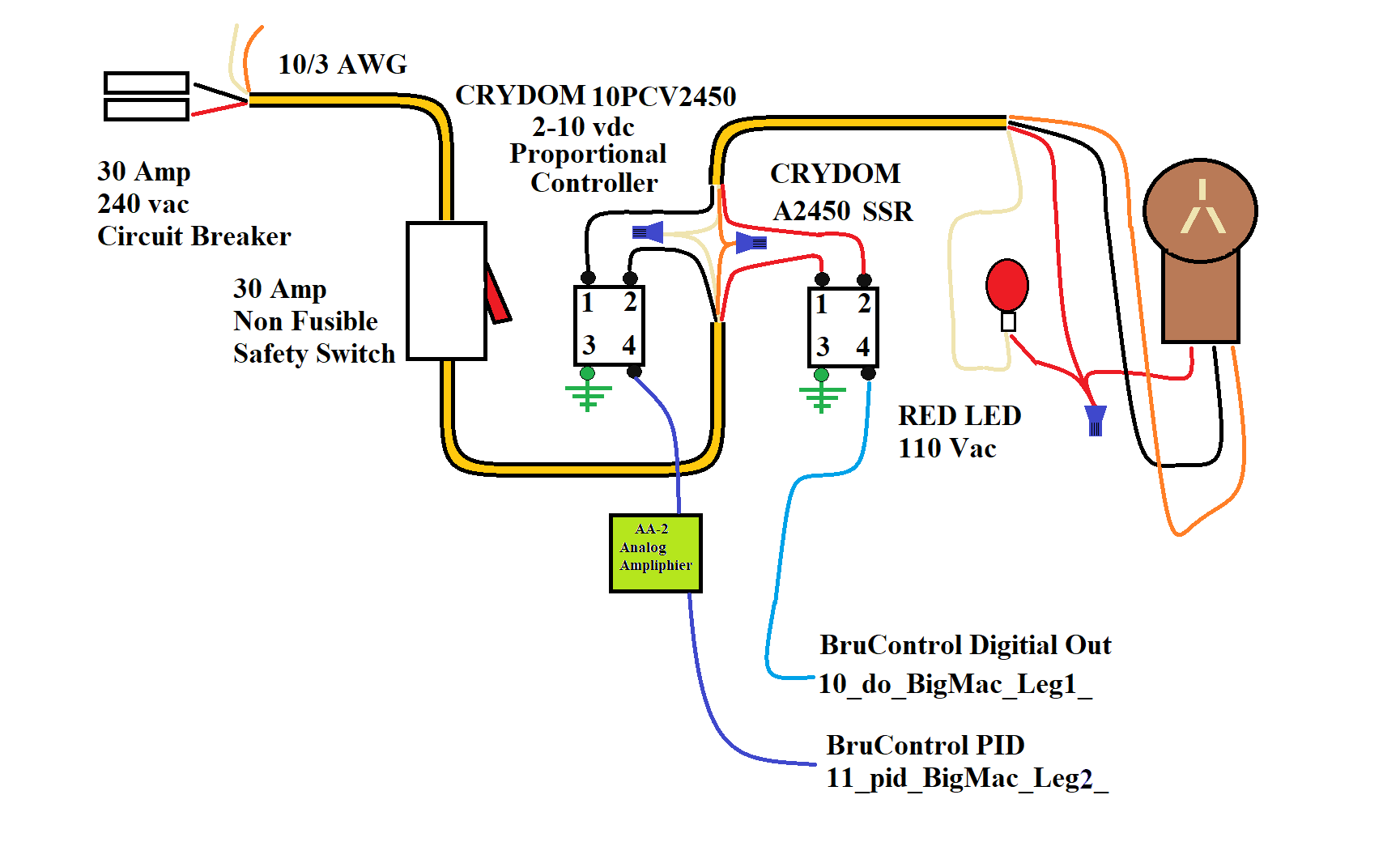

Is my logic correct?

I am about to start my wiring for the Brewery.

I have an HLT that I named "Big Mac". It has a 5500 watt element.

I plan to use the PID Control.

View attachment 719967

I do not like

any hot leg to the vessel unless it is "On".

I always put a Cut Out Safety Switch in my line away from the Brewery

I like to "know" that the heater is commanded "On" by a small LED Bulb.

I will be using 30 amp Circuit Breakers and one standard SSR for

Leg 1

The PID will be via an AA-2 Analog Amplifier and a Proportional Control (2-10 input) for Leg 2.

My plan is to command Both the Standard SSR Digital Out (

Leg 1) and the PID Proportional Controller (Leg 2) at the same time. The Standard SSR will be hot to the Outlet as well as turn on the Red LED letting me "know" BruControl has powered the standard SSR (

Leg 1)

The Outlet will provide PID control via Leg 2 Proportional Control (2-10 input) with the Target and Temp set for that PID.

I know that an HLT may not need the precise control. I have other parts that are similar that do need the precision of a PID, that will be wired the same. My HLT would be a backup for that if I needed it.

Regardless, Is this a good way to use PID Control for a 240 volt Element?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)