RiverCityBrewer

Well-Known Member

I think you could use Ethernet jacks and wiring for sensors, but you would be missing out on the benefit of shielding.

I think you could use Ethernet jacks and wiring for sensors, but you would be missing out on the benefit of shielding.

Sure, if you have STP at your disposal, then use it, just make sure to ground the drain wire at the panel side.

I am thinking of this myself, but I am not sure how to add DIN rails to the box.

I was going to try this (although, I am nowhere near this step). I am going to do research on the wiring first to make sure there wont be any loss.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I'm not sure I understand, here is the breakdown of each I/O connector that I am working from...If you are more comfortable crimping vs soldering and are ok with the increased costs, I think the shielded patch panel will work fine. Keep in mind that the UniCon has 8 IO, but there are typically more than 8 wires associated with those 8 IO points. For example, the valves I use require 3 wires (power open, power close, and ground). Some valves use 2 wires, and some can use up to 5 if you want feedback from them. For sensors, you will have to get power to them as well as bring the signal back to the controller, so 3 and sometimes 4 wires per sensor.

Sure I am willing to share everything I learned. I used brucontrol site and schematics posted there as guidance.That looks really nice! I've been doing some research on this for the past month or so. Would you be willing to share your parts list with me?

Has anyone used a small PC like a Nuc or zbox to run BruControl? I was thinking of adding one inside my panel and adding a 22 to 24" touch monitor to one of the three cabinets and high voltage in one and low voltage in the other. I also wanted to use Ethernet jacks for the I/O to sensors and wanted to know if that has been done successfully or not.

I do networking in my day job and I am pretty sure Cat5e and Cat6 are shielded and twisted pair inside so that should cut down the chance of picking up noise don't you think?

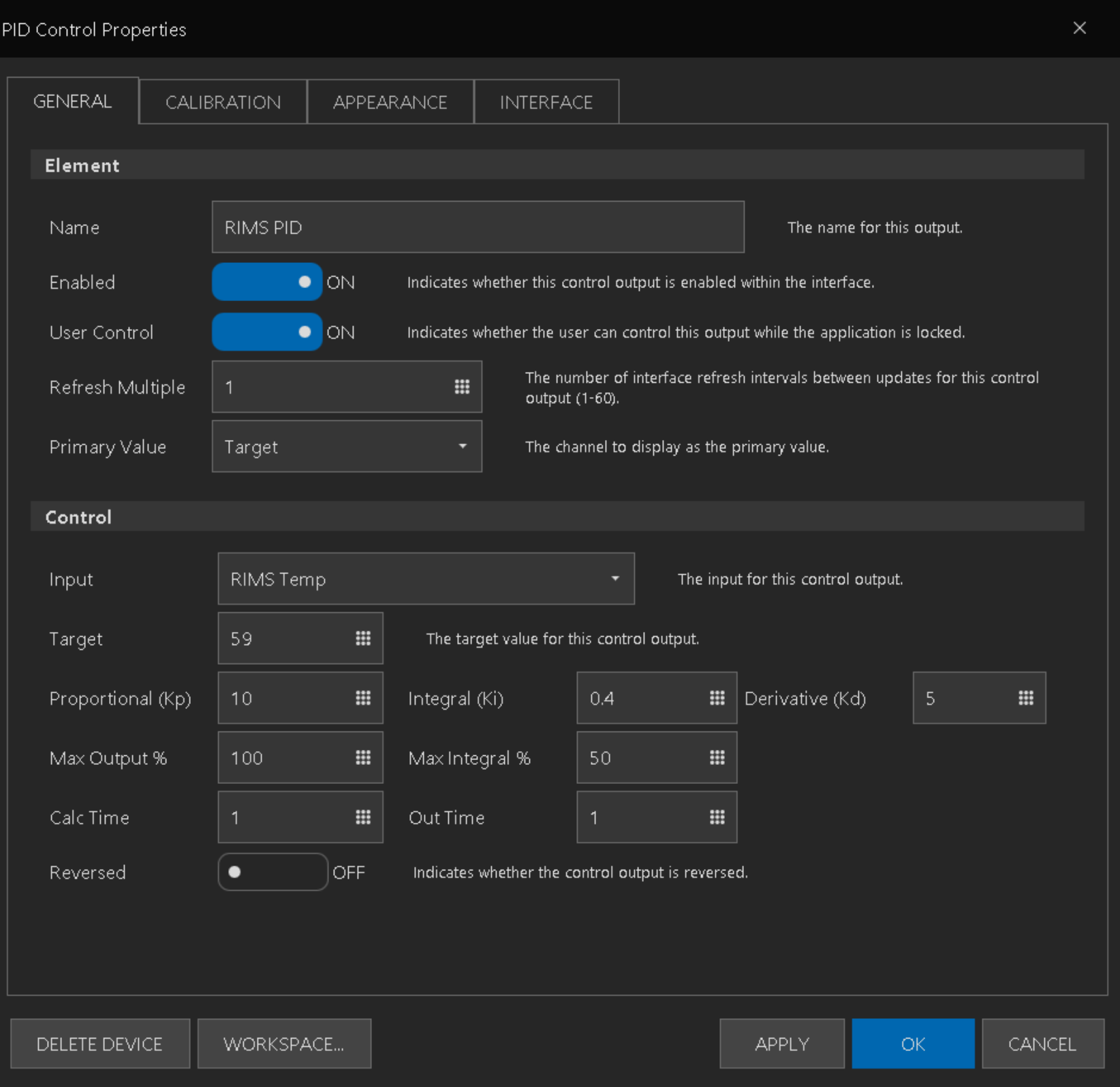

I think I should be ok with1st PID tuning - for my setup.

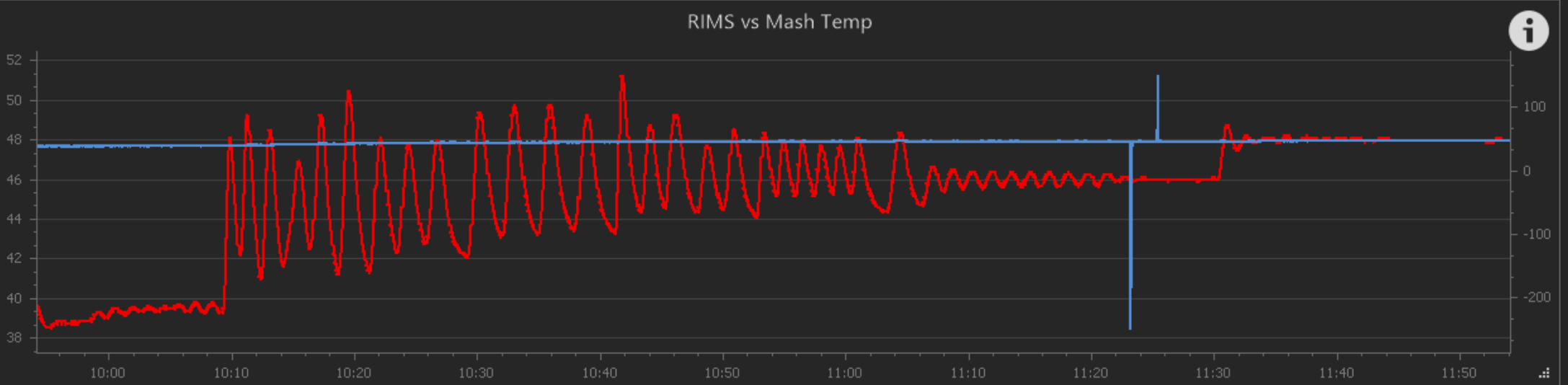

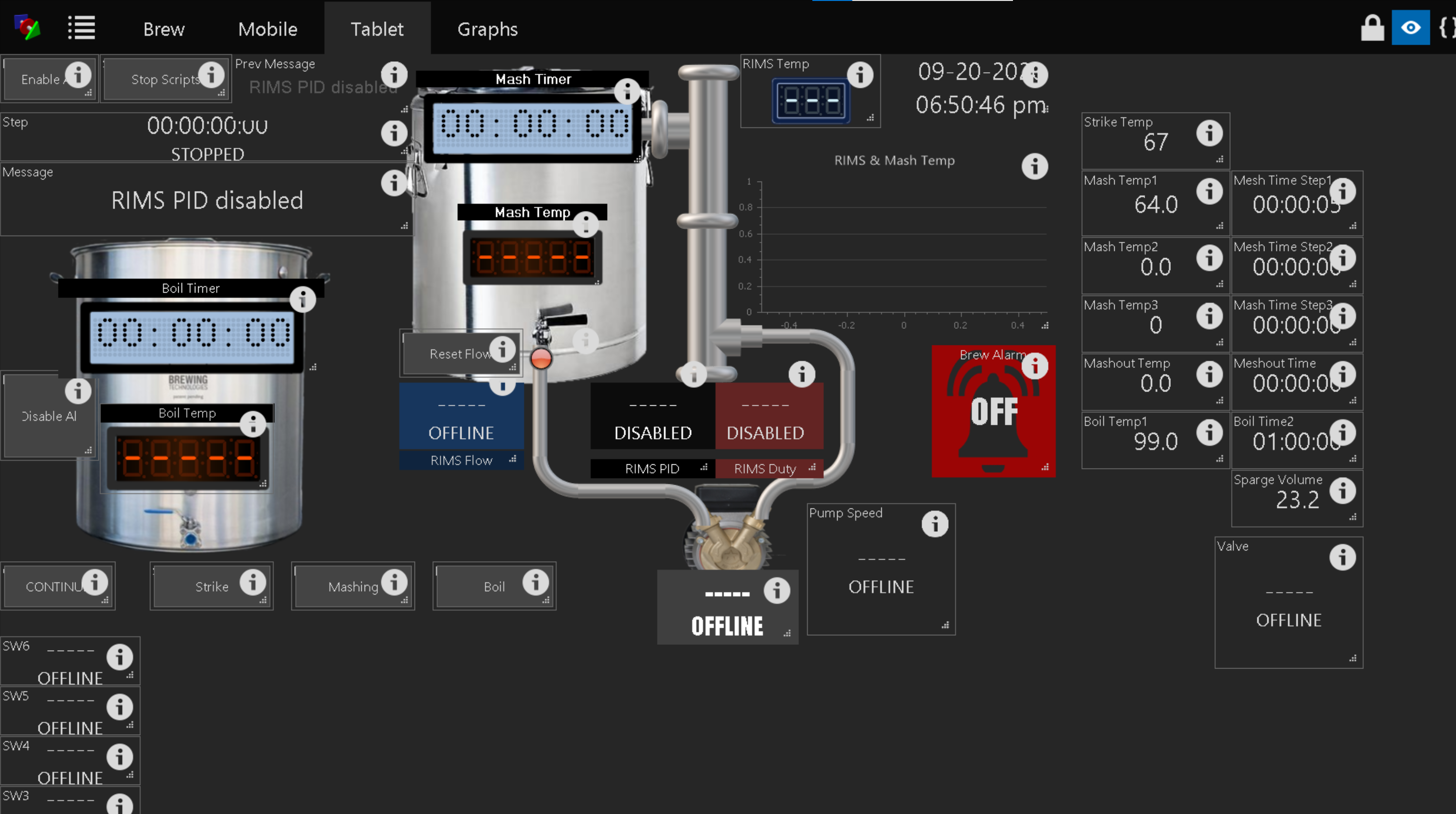

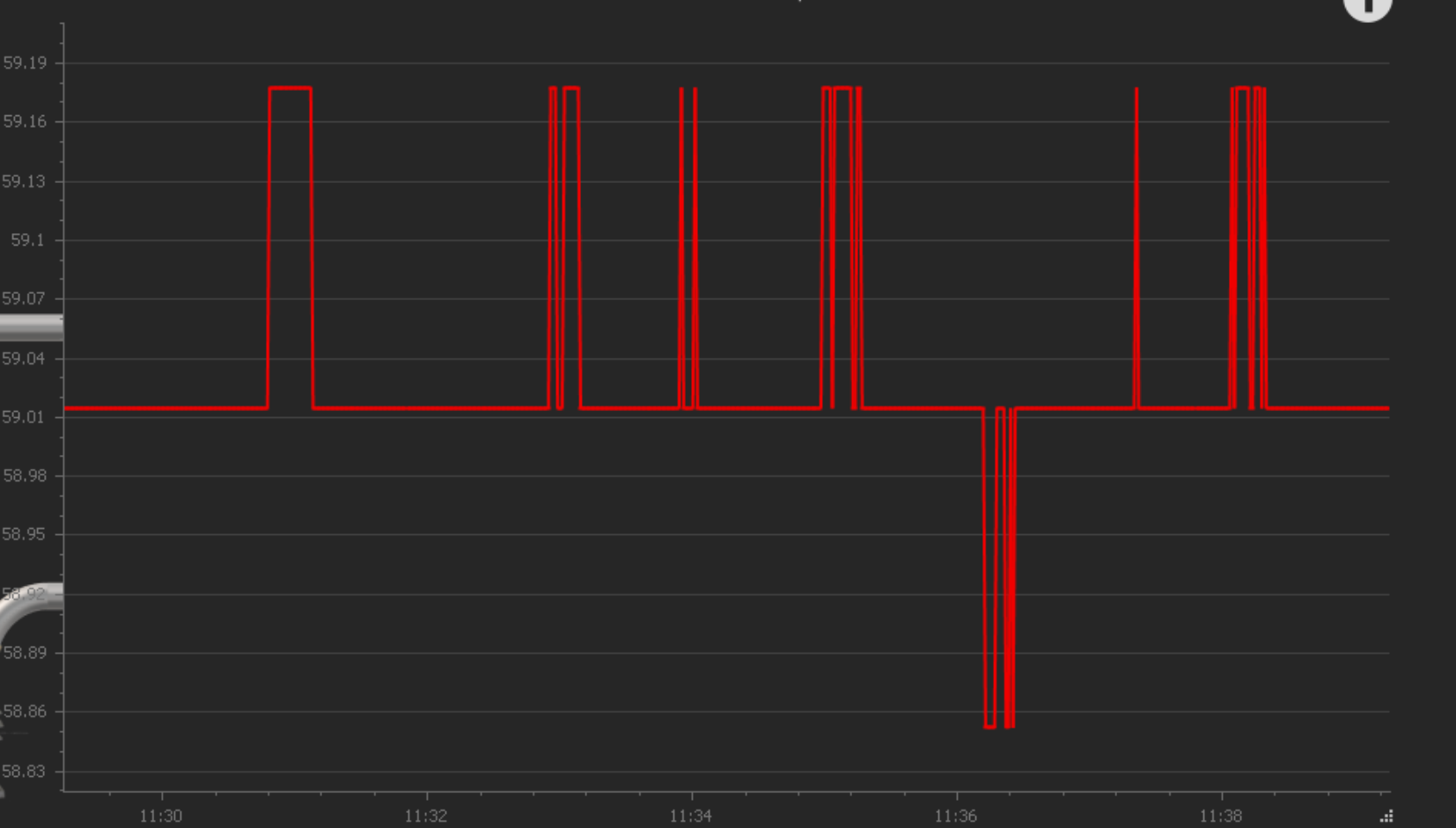

Flow was 2L/minute, 5, 0.1, 0 worked just fine. I am unsure if this is realyl good. Temp is within 0.1 deg from target temp. What do you think?

View attachment 699243

Where is the temp probe here? I'm not surprised of the big swings if this is in the RIMs tube at this slow a flow rate. What is the blue line? What happened at the ~11:30 mark that caused the alignment to the blue line?

What 8 pin connectors are you using for panel I/O and what is their approximate cost? I sourced the Ethernet solution at approximately $1.70 per I/O connection and I am having difficulty locating 8 pin aircraft panel connectors as you site in the video.Just note that these are typically solid wire, so are prone to fracture with frequent bends. Otherwise, I think this wire can be successfully used.

At or a bit before 11:30, I changed target temp to 52C. System just followed my inputs.

Temp probe is just above heater, maybe 2cm or less above it. heater is 3.5 kW. System reacts quite fast after heater is on / or when it's pulsing.

With PID 20/ 1 / 5 swings are way to big for my system. Check the begining of the graph.

What would be the recommenderd flow rate?

I can increase it for sure, but then PID numbers will have to change. I was under impression that would be good flowmaybe my conversion from imperial to metric failed again.

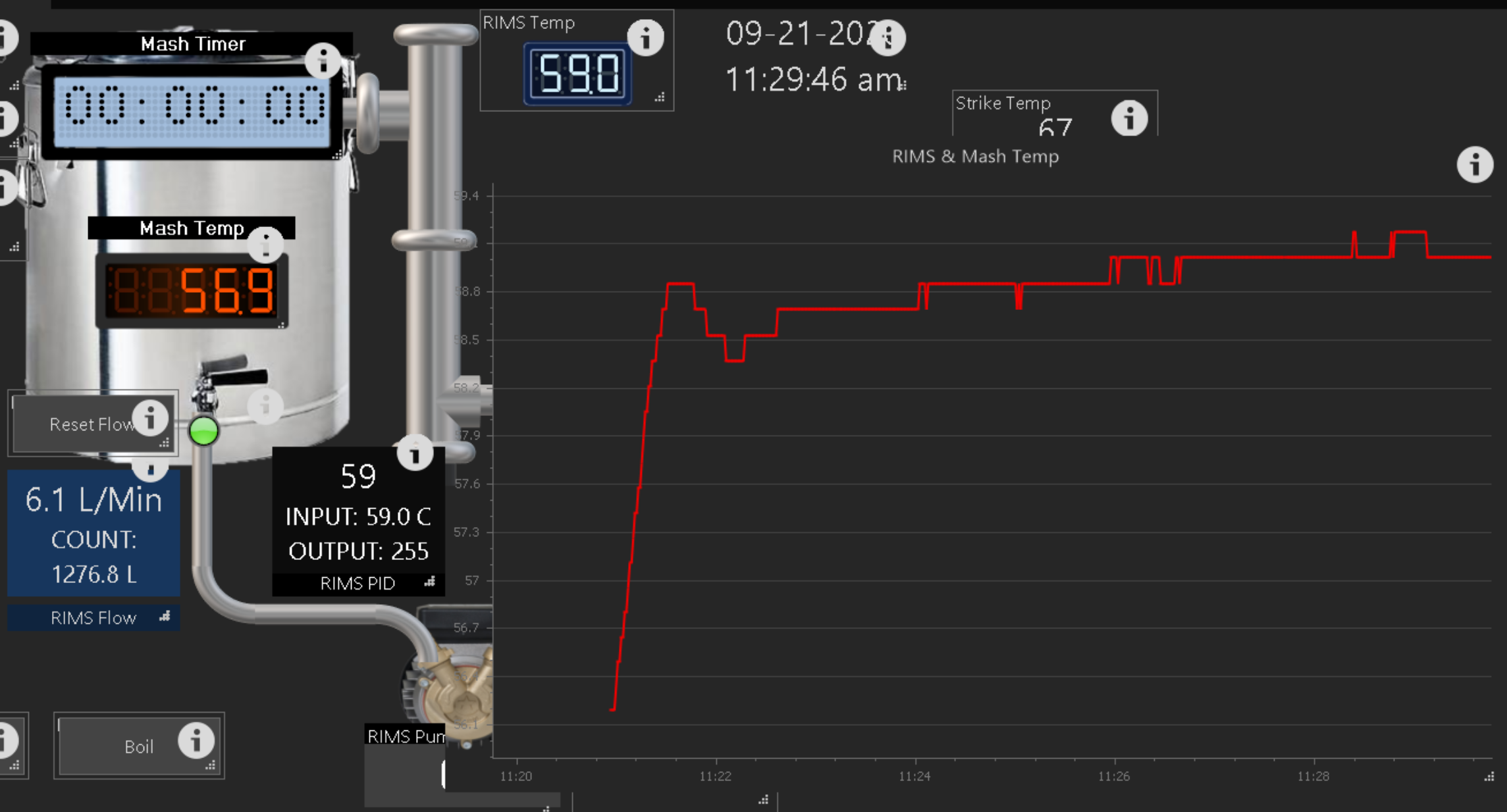

Are you saying the temp probe is in the RIMs tube? I'm saying the flow rate is very slow if you are at 2 lpm (1/2 gal/minute). This is about 2x sparge rate. In my rig, it flows as much as 6 gal / min (24 lpm) when the mash is fully settled. I would suggest at least doubling your flow rate to 4 lpm or more.

Would love to see more pictures of the inside of your panel! Looks great so far!Hi everyone,

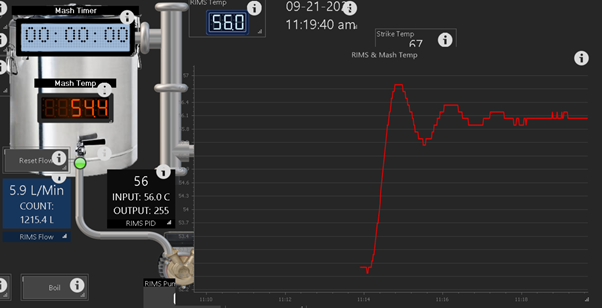

Sorry for redirecting the topic, just want to share couple picture with you.

For past weeks and months, as I was building my setup and silently followed this group.

Finally I am ready, and I did my first PID tuning:

View attachment 699242View attachment 699244 I

I think I should be ok with1st PID tuning - for my setup.

Flow was 2L/minute, 5, 0.1, 0 worked just fine. I am unsure if this is realyl good. Temp is within 0.1 deg from target temp. What do you think?

View attachment 699243

Cheers

Would love to see more pictures of the inside of your panel! Looks great so far!

I assumed the issue was with the bootloader file (bootloader_qio_80m.bin), so I pulled down the latest bits from Github for the ESP32. I swapped the latest of bootloader_qio_80m.bin into the resources folder but had no luck with it. For grins, I then swapped the bootloader_dio_80m.bin in, modified the script, and now it seems to have loaded correctly. I'm not sure what the long term ramifications are of that, and I haven't tried flashing any of my older ESP32 boards with the current configuration. I'll be curious to see if you have the same issue with the 32E version as well.

Firmware updates can be found hereCan someone tell me please what's the latest versions of firmware for MEGA and brucontrol software you are using ?

And how to download that pre-relesses or "beta" brucontrol and corresponding fw?

I've seen on the live video UI elements with enable disable slider on each and I like that a lot, but I don't have it.

Firmware updates can be found here

https://brucontrol.com/download/firmware

Latest releases here

https://brucontrol.com/downloadx-page/

Are you saying the temp probe is in the RIMs tube? I'm saying the flow rate is very slow if you are at 2 lpm (1/2 gal/minute). This is about 2x sparge rate. In my rig, it flows as much as 6 gal / min (24 lpm) when the mash is fully settled. I would suggest at least doubling your flow rate to 4 lpm or more.

Following up on this... I tried an ESP32.. 32E with the 45N firmware using the Universal Install tool and it worked correctly on the first try. So... not sure whats up with the unit you have.

or flash text message: "text" -> "nothing" -> text[start]

"Alarm 1" Background = 1

sleep 500

"Alarm 1" Background = 2

goto start

yep that was it, thanks a lot ! I am confused a bit how sleep works with goto.You need another sleep 500 after you switch the alarm background to 2. Without a pause there, you are changing to 2 but immediately changing back to 1, so you never see it change.

Sleep will always wait the time set at that line before advancing to the next line.

Goto will always immediately jump to the set place and execute the next line.

Just keep in mind that the BC interpreter can process thousands of lines of script per second (probably more), so if you need to *see* something happen on the screen, sleep and wait commands are your friends.

[start]

"Alarm 1" Background = 1

"Alarm 1" Background = 2

sleep 500

goto start

[start]

"Alarm 1" Background = 1

sleep 500

"Alarm 1" Background = 2

sleep 500

goto start

[start]

"Alarm 1" Background = 1

"Alarm 1" Background = 2

goto start

Still in the planning phase and updating my scripts.

The HLT will have two 220v Elements. In my old system, I only had one 220v Element and I used a 24vac SSR to control an Double Pole Electrical Contactor using Hysteresis. That way, there was not a Hot Leg waiting for a ground at the Element.

Since I will be running all new wire, I can run 10/4 AWG and use Nema 14-50 (I like the Larger Lugs) Plug and Receptacle and use something like a Crydom MCPC1250C and use PID Control as I will now have the extra Ground Safety. How do I do that with two Elements. After we reach temp, have one on Duty Cycle and the Other PID? Use the new Dual Throw control both as PID?

Or should I use the Electrical Contactor like before and Hysteresis for safety like before. Looking for some insight if someone is doing this.

I am not sure how you would control two Elements in the same vessel. I assume that the Quadzilla use has some logic that you could use with that. If I understood the control logic of how to use the Quadzilla, I would know how to wire the new brewery for multiple Elements in the same vessel.Sorry... I don't understand what you are asking or looking to do.