- Joined

- Jan 28, 2013

- Messages

- 3,926

- Reaction score

- 3,026

Hey just want to extend my most sincere THANK YOU to @highland_brewer for hosting me today on his live brew day!! He is the quintessential gentleman... as well as being a good multi-tasker. Most importantly, he manages surprises really well!!!

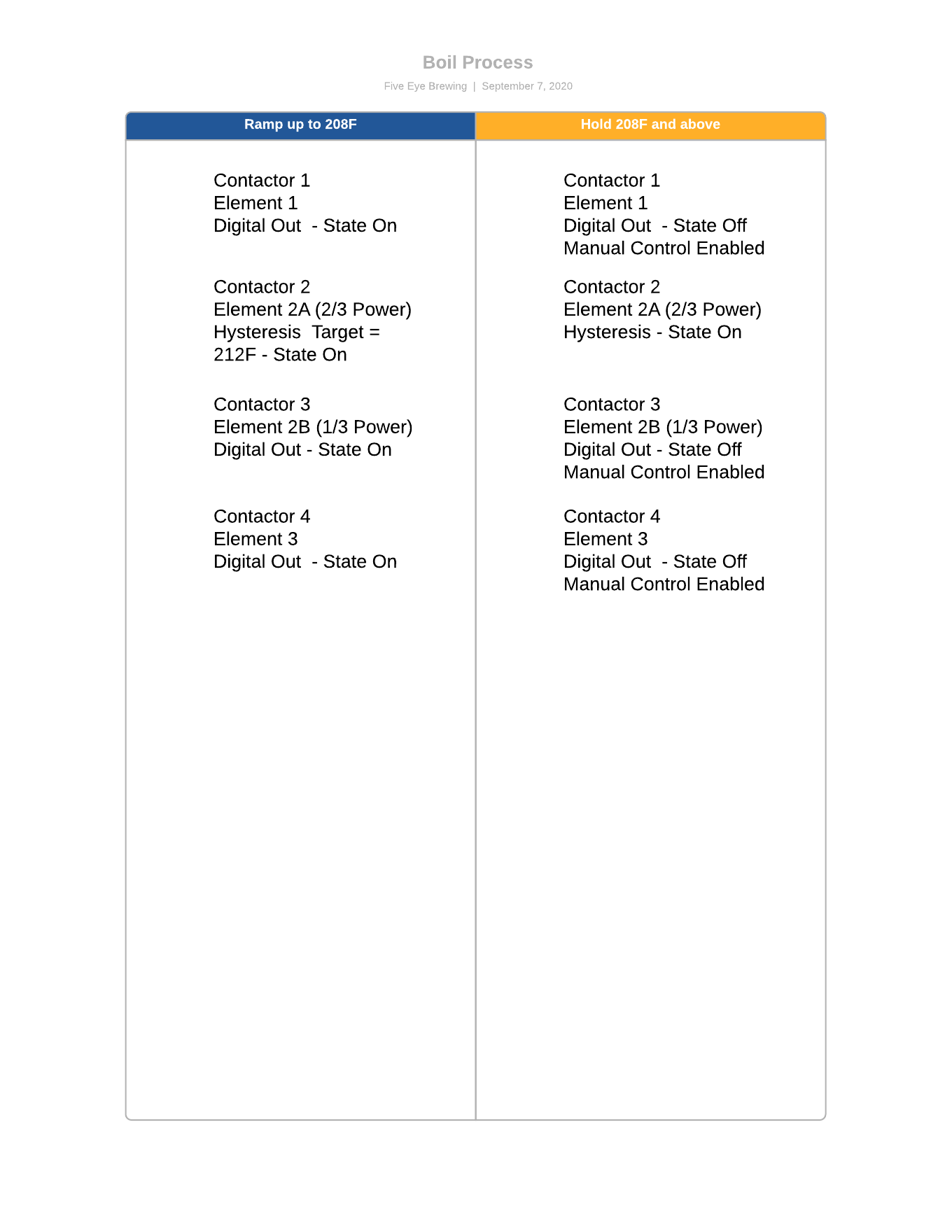

Here is the link again - check it out when you get a chance to see the UniFlex and BruControl in action:

Came and went a few times through out the brew day...was interesting learning about all the automation! Controller looked awesome!

Nice job as always @highland_brewer!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)