Similar here, a 9v supply just for one board is just nonsense. Not even going to argue that, it is just silly...

I have a 12V that powers the 2-10v signal for the analog amplifier board and a 24VDC for the industrial automation things, and a a 24VAC transformer for my Johnson proportional control valves. Adding a 4th power supply is something I will fight very hard.

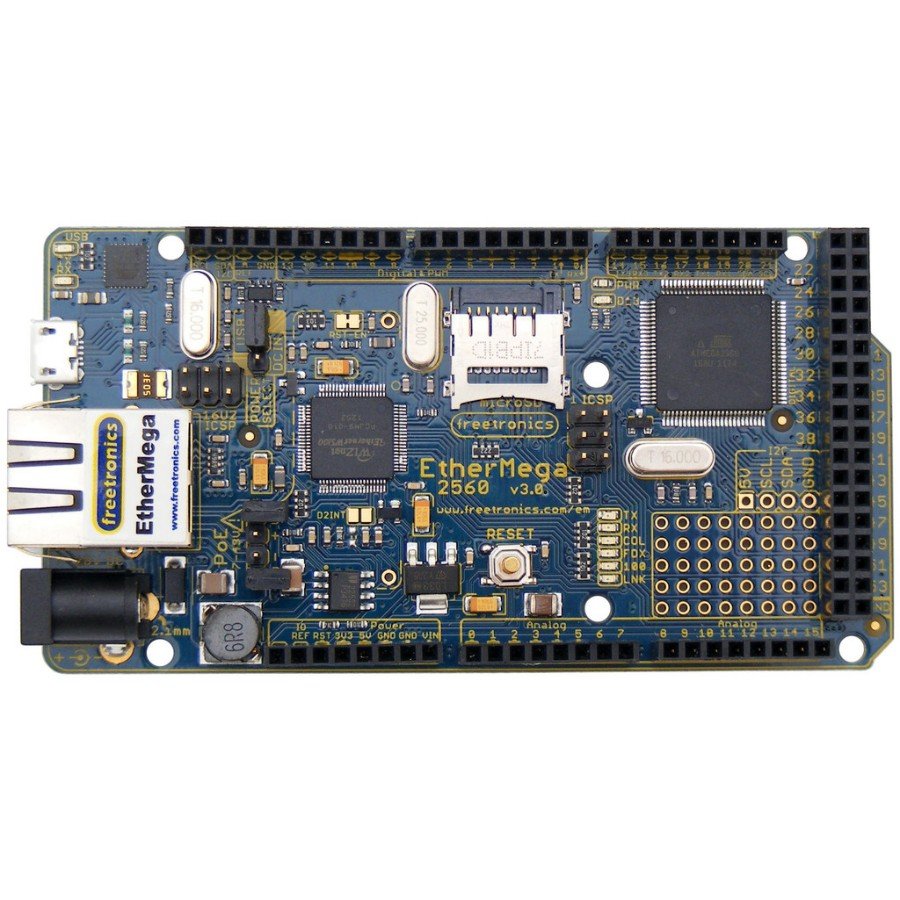

IMHO, a din-rail screw shield with an installed (or just the traces to install) a

$1 buck-boost converter seems to be the logical solution ...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)