Tested the ESP32... its not working. But you knew that. We'll need to put some time in to see why. BTW we used the VSPI pins... 5, 18, 19.

I am i correct in thinking if the wiring map uses SPI, those pins may have to be disallowed from other use?

Tested the ESP32... its not working. But you knew that. We'll need to put some time in to see why. BTW we used the VSPI pins... 5, 18, 19.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

BrunDog, I am interested in getting the draw.io source for the 50a system schematic. Also, is there an electrical symbol library for draw.io? I am not having any luck finding one. Thanks.

Edit: Oh, I see electrical symbols under more shapes.

"Step Timer" Value = "Mash Timer" Valuenew time mashtmr

mashtmr = "Mash Timer" Value

"Step Timer" Value = mashtmrnew string strikestatus

strikestatus = "Add " + "Strike Water Amount" Value + " gallons of water to MLT and " + "Sparge Water Amount" Value + " gallons of water to HLT."

"System Status" Value = strikestatus

if "Script 1" State == true

print "Script 1 Running"

endifResponding to above post:

This should work fine (does in my testing), as long as both 'Step Timer' and 'Mash Timer' are both timer elements or global elements (using either time or datetime type data). Also, you declare a time variable but don't use it in the example, so I'm not sure what your intention is there.Code:"Step Timer" Value = "Mash Timer" Value

This works fine. Are you sure you have 'Step Timer' as a Global with time type variable?Code:new time mashtmr mashtmr = "Mash Timer" Value "Step Timer" Value = mashtmr

You cannot do this because the interpreter cannot handle inline math yet.Code:new string strikestatus strikestatus = "Add " + "Strike Water Amount" Value + " gallons of water to MLT and " + "Sparge Water Amount" Value + " gallons of water to HLT." "System Status" Value = strikestatus

Repository is a good idea. We have a user forum that isn't used much. I suppose that would be a PITA for users to bounce forums. Perhaps the HBT guys would be OK with a BC script thread? Happy to field suggestions here.

Importing is done via a third party interpreter. I think most are using NodeRed to read the XML and hand it to the Data Exchange protocol in BC. We do not have a native XML reader yet, and honestly have back-burnered it in favor of the data exchange. We could resurrect if enough support.

restart "Step Timer"I'm not following you... Whatever is in quotes like "Step Timer" must be an element... that element has certain properties, like value. You need to use the reference a property that actually exists for that element, per the manual.

That said, if you are using a timer element on screen, you can continue to use it... just reset it as you go:

Code:restart "Step Timer"

No doubt, scripting can be be one of those things where trees disappear in the forest! We have bounced around a pre-interpreter which could flag issues before they run, but haven’t got to it just yet.

I am dumb. The error is coming from the line after. I was trying to calculate a "Remaining Time" and display it as a string. Did not work.

I was also able to use a WAV for a custom alarm sound (Alien Siren).

I am dumb. The error is coming from the line after. I was trying to calculate a "Remaining Time" and display it as a string. Did not work.

I was also able to use a WAV for a custom alarm sound (Alien Siren).

I am dumb. The error is coming from the line after. I was trying to calculate a "Remaining Time" and display it as a string. Did not work.

I was also able to use a WAV for a custom alarm sound (Alien Siren).

yeah, it would have to come with a big disclaimer that any other software running on it might screw the pooch... One thing I know is that I can SSH and reboot a Pi ZeroW, and I cannot do that to a ESP32/8266.... walking up and down stairs is good exercise, but getting tiresome...

The whole point of using a micro-controller is they don’t crash.

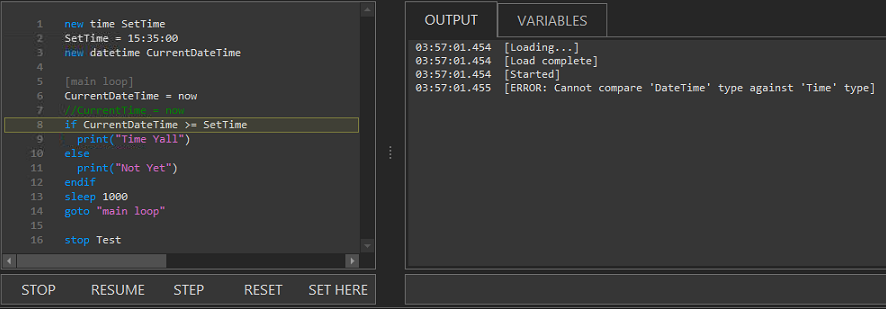

@BrunDog How can I achieve something like this below? I want to be able to compare the current time to a time variable or global without a date attached to it. As far as I can tell I have to use a datetime variable and keep adding one day to it once every 24 hrs to get things to happen at a specific time each day.

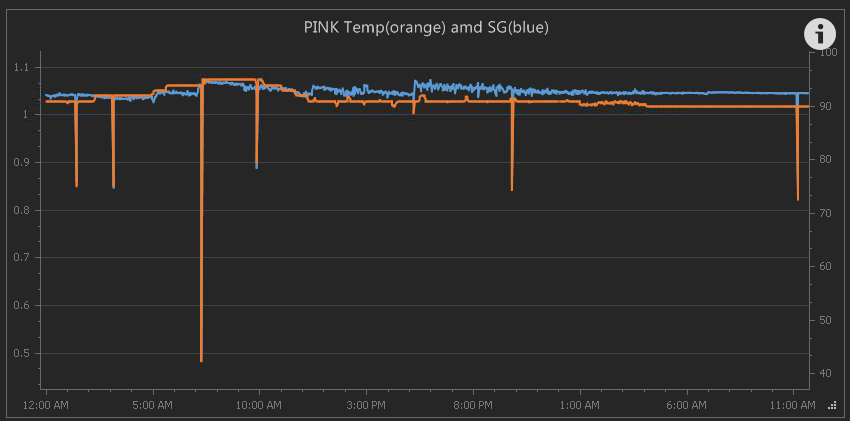

View attachment 644735