Question - after flashing a SonOff or ESP32 with BruControl firmware, it is possible to send http commands to read temps or set outputs?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Gameface

Well-Known Member

Does the arduino mega need either the analog amplifier board or a DIY low-pass filter to use the proportional valves? I didn't see it listed on the order list?

Question - after flashing a SonOff or ESP32 with BruControl firmware, it is possible to send http commands to read temps or set outputs?

No, sorry. The communication protocol does not use http.

Does the arduino mega need either the analog amplifier board or a DIY low-pass filter to use the proportional valves? I didn't see it listed on the order list?

Correct, either is required to convert PWM to analog voltage. The AA provides better isolation, depending on the current requirement of the proportional device you are tying to control.

Edit: FYI there are some interfaces, like the ESP32, which do have true analog outputs, but its range is 0-3.3V, not 5V, so an amplifier is still needed to get a 0-5V analog range.

Gameface

Well-Known Member

I purchased the amplifier board.Correct, either is required to convert PWM to analog voltage. The AA provides better isolation, depending on the current requirement of the proportional device you are tying to control.

Edit: FYI there are some interfaces, like the ESP32, which do have true analog outputs, but its range is 0-3.3V, not 5V, so an amplifier is still needed to get a 0-5V analog range.

Wizard_of_Frobozz

Well-Known Member

I found some very reasonably priced sensor cable that looks pretty good for use with BruControl:

https://www.automationdirect.com/ad...ted_pairs_with_individual_-a-_overall_shields

Overall and individual shielded multi-conductor cable in 18 & 16 awg wire sizes. Can get it with 2, 4, or 8 twisted pairs. Also includes a 22 awg signal wire in the cable.

There's a 20 ft minimum order, but it's cut to length and the price is very good considering what you get. Ill be ordering some along with terminal blocks and wire duct for my panel build. Electricians where I work order all kinds of stuff from them and are very happy with what they get.

https://www.automationdirect.com/ad...ted_pairs_with_individual_-a-_overall_shields

Overall and individual shielded multi-conductor cable in 18 & 16 awg wire sizes. Can get it with 2, 4, or 8 twisted pairs. Also includes a 22 awg signal wire in the cable.

There's a 20 ft minimum order, but it's cut to length and the price is very good considering what you get. Ill be ordering some along with terminal blocks and wire duct for my panel build. Electricians where I work order all kinds of stuff from them and are very happy with what they get.

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

I use this and am pretty happy(would like a more rubbery insulation sheath):

50' cable - carol digikey C2526G-50-ND $16.53

I bought this 20ga and it was way to big to be used as sensor cable unless you are using full size XLR... I think 18 and 16 are going to be even more bulky...

Carol C1304 20/3C Premium Braid Shielded Low Impedance Microphone Cable Bk/100ft ($55 on eBay)

50' cable - carol digikey C2526G-50-ND $16.53

I bought this 20ga and it was way to big to be used as sensor cable unless you are using full size XLR... I think 18 and 16 are going to be even more bulky...

Carol C1304 20/3C Premium Braid Shielded Low Impedance Microphone Cable Bk/100ft ($55 on eBay)

Wizard_of_Frobozz

Well-Known Member

I use this and am pretty happy(would like a more rubbery insulation sheath):

50' cable - carol digikey C2526G-50-ND $16.53

I bought this 20ga and it was way to big to be used as sensor cable unless you are using full size XLR... I think 18 and 16 are going to be even more bulky...

Carol C1304 20/3C Premium Braid Shielded Low Impedance Microphone Cable Bk/100ft ($55 on eBay)

Good point on the difficulty in working with larger wires. I had some concerns with going too small; Cat 5e/6 cable would give you twisted pairs, which helps for noise reduction, but is typically around 22-24 gauge, and I worry about the wire strength at the terminations when you get that small. Your solution looks pretty good; not twisted pairs, but it is shielded, which might be enough for our applications.

I solder it directly to the shortened pins of the DS18B20, heat shrinking the Data and Vcc and then all the connections leaving the sensor plastic exposed and slide it into the thermowell ( ss tubes 10x6mmx100mm ebay redrose999 10 for 9.99 ) the other end I connect to the small M8 metal aviation plugs...

and it has the small cable like steel wire inside, you could lift a car with a couple pieces...

and it has the small cable like steel wire inside, you could lift a car with a couple pieces...

What is the best way to get a Tilt working with BruControl. I have a Feather M0 and a couple ESP32's in the bags still, will either of these work? The last thing I saw was using a Primo...

The ESP32 will work... once we issue v1.1!

Looking forward to this, had a brand new from scratch install of CBPi on a Pi3B lock up last night and let 2 ferments that were monitored with Tilt, and cooling controlled by TILTplugin and MQTTplugin talking to Tasmota-SonOff get out of hand and overshoot by 10 degrees... and all the syslog has is an 11 hour gap between entries... grrrr...

I think stranded cable is better than solid, for both power and signal, but you can certainly use solid, especially inside an enclosure or where it is not going to be moving at all.

Looking forward to this, had a brand new from scratch install of CBPi on a Pi3B lock up last night and let 2 ferments that were monitored with Tilt, and cooling controlled by TILTplugin and MQTTplugin talking to Tasmota-SonOff get out of hand and overshoot by 10 degrees... and all the syslog has is an 11 hour gap between entries... grrrr...

Sorry man! Frustrating!

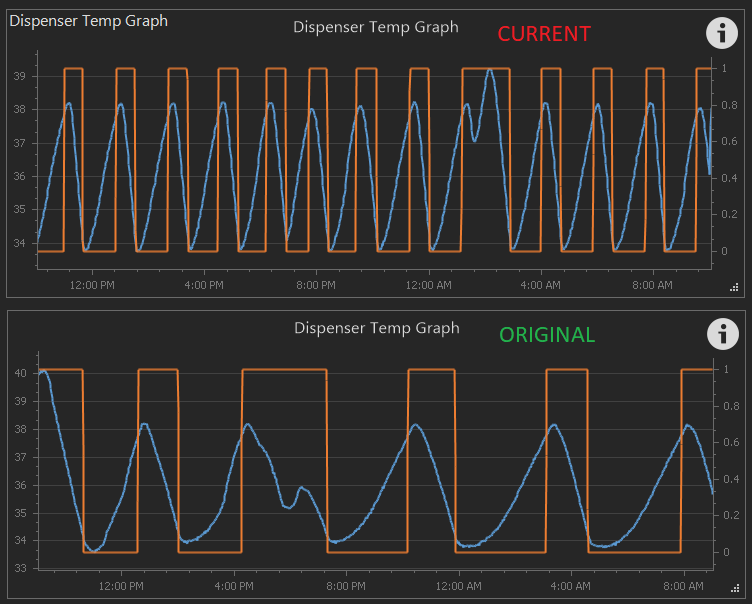

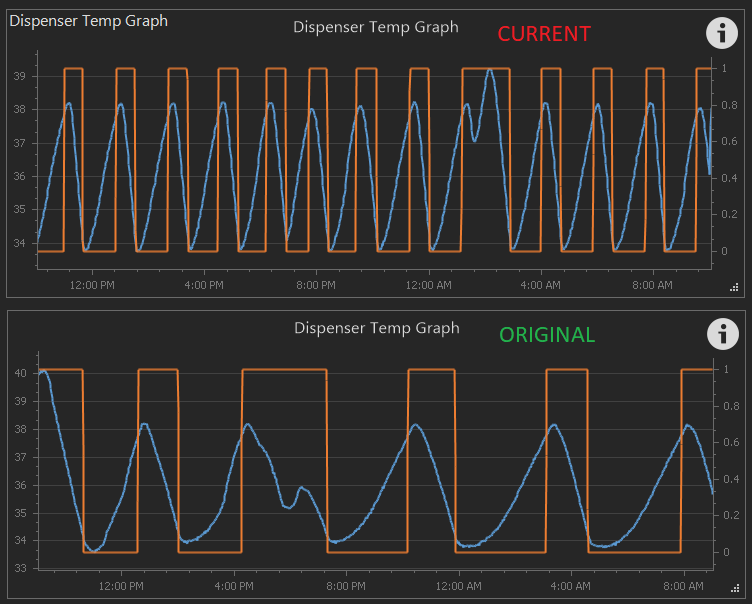

A great reminder that graphs matter... I noticed by the graph my dispenser seemed to be cycling a lot more than usual. Did a comparison to an older screenshot and sure enough, it was. My temp probe is a sensor located down into a thermowell inside a wine bottle of water. The goal of this is to measure the temp and have temp changes be appropriately buffered by a body of liquid (too little and lots of cycling occurs... too much and too much temperature swings occur). BTW this is why I don't think you should every run your fermenter's temperature control off a thermowell buried deep into the fermenter.

Anway, sure enough, the probe somehow got pulled back (kids mucking around in the shared beer dispenser / drink fridge) and the sensor was near the entrance to the thermowell, so it wasn't getting appropriate damping. Two graphs overlaid... top is now and bottom is normal.

Anway, sure enough, the probe somehow got pulled back (kids mucking around in the shared beer dispenser / drink fridge) and the sensor was near the entrance to the thermowell, so it wasn't getting appropriate damping. Two graphs overlaid... top is now and bottom is normal.

Anybody use a mini PC to run Brucontrol? Something like this.

https://www.amazon.com/gp/product/B07GD95D6K/?tag=skimlinks_replacement-20

Reading through the documentation, looks like 8GB of RAM is recommended, so this is a bit light duty in that regard.

https://www.amazon.com/gp/product/B07GD95D6K/?tag=skimlinks_replacement-20

Reading through the documentation, looks like 8GB of RAM is recommended, so this is a bit light duty in that regard.

canmorebrewguy

Well-Known Member

- Joined

- Oct 5, 2015

- Messages

- 103

- Reaction score

- 15

I am using this Mini pc https://www.amazon.ca/gp/product/B078HK2QXN/?tag=skimlinks_replacement-20and it is a little slow to start brucontrol but works great while running. I have 3 brews using it now.Anybody use a mini PC to run Brucontrol? Something like this.

https://www.amazon.com/gp/product/B07GD95D6K/?tag=skimlinks_replacement-20

Reading through the documentation, looks like 8GB of RAM is recommended, so this is a bit light duty in that regard.

Cheers,

Todd

I am using this Mini pc https://www.amazon.ca/gp/product/B078HK2QXN/?tag=skimlinks_replacement-20and it is a little slow to start brucontrol but works great while running. I have 3 brews using it now.

Cheers,

Todd

Thanks for the response! I think I'll go ahead and get something with similar specs.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Just remember you don't need the pc in the panel per say. Having tested and found the limits of USB, I MUCH prefer Ethernet. For instance I run it on a server, in my equipment room not located by the brewery. Since all my stuff is Ethernet based it acts as basically a "cloud" server.

Got it. I was just looking for something with a small form factor, WiFi and with HDMI output. It'll probably sit on a table close to the brewery in the garage.Just remember you don't need the pc in the panel per say. Having tested and found the limits of USB, I MUCH prefer Ethernet. For instance I run it on a server, in my equipment room not located by the brewery. Since all my stuff is Ethernet based it acts as basically a "cloud" server.

purdman10

Well-Known Member

BrunDog, I am in the process of adding solenoid water valves to my rig- I have six 12v dc ss valves to attach and want to add two proportional water valves you have for sale. I already have a 30A 12v dc power supply and a 5A 5v dc supply and they take up much room along with a 24v ac transformer for propane valves. I suppose I will have to make room for a 24v dc power supply too... I did not see a 24v dc power supply in your build list. What do you use to power the proportional kld valves? Thanks.

The proportional valves use 24 VDC.

FYI, solenoid valves use a lot of juice and will generate heat when on for a long while - just make sure they are 100% duty rated. They also incur a rip of EMI on power-off. Make sure you have fly-back diodes on them (1N4001 or better).

FYI, solenoid valves use a lot of juice and will generate heat when on for a long while - just make sure they are 100% duty rated. They also incur a rip of EMI on power-off. Make sure you have fly-back diodes on them (1N4001 or better).

purdman10

Well-Known Member

Thanks for the info, I didn't know about he electrical characteristics. Good to know! My question is what is an example of the power supply that will be needed- what do you power yours with?

purdman10

Well-Known Member

I misspoke - the water valves are baco electrical valves.

Any quality switching supply will work. I use a TDK Lambda unit... I think it’s 30W.

purdman10

Well-Known Member

Thanks, BrunDog.

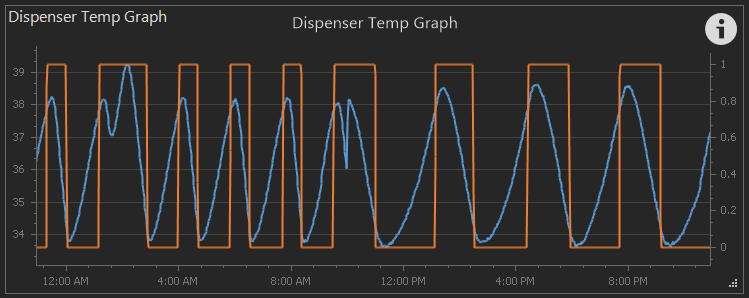

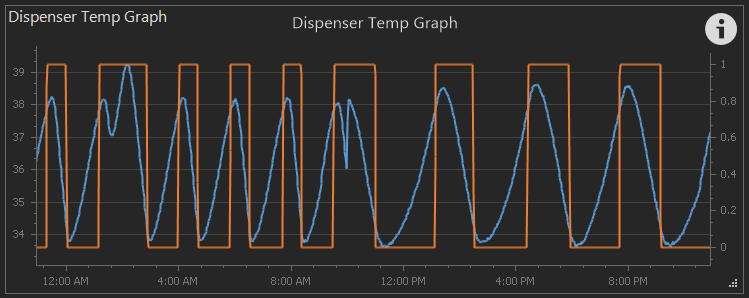

Following up from earlier... what a difference fixing the sensor location made. You can see the cycling improve right away.

augiedoggy

Well-Known Member

Im using a mini but its not quite that small.. I have one of these with windows 10Anybody use a mini PC to run Brucontrol? Something like this.

https://www.amazon.com/gp/product/B07GD95D6K/?tag=skimlinks_replacement-20

Reading through the documentation, looks like 8GB of RAM is recommended, so this is a bit light duty in that regard.

https://www.ebay.com/itm/HP-Elite-8...epid=1237055951&hash=item21404baa46:rk:4:pf:0

I only have 6 gb or ram but it works fine (I have the 8gb upgrade kit sitting on my desk) Its the reliability of those android box type micro pcs that bother me after having 3 of them fail (andriod tv boxes used for kodi and the like).

augiedoggy

Well-Known Member

I use a 4 amp 24v supply for my solenoid valves but they are the cheap $3 variety (at home)... I believe the 12v valves I just bought for the brewery state they use 1500ma each.. as brundog mentioned I needed to add the flyback diodes due to noise.Thanks for the info, I didn't know about he electrical characteristics. Good to know! My question is what is an example of the power supply that will be needed- what do you power yours with?

I just finished my fermentation control panel last night for the brewpub. hope to have everything running today.

canmorebrewguy

Well-Known Member

- Joined

- Oct 5, 2015

- Messages

- 103

- Reaction score

- 15

Where would these go in a solenoid valve wiring schematic, I am using solenoid valves for my can filler and wondering if I need these?The proportional valves use 24 VDC.

FYI, solenoid valves use a lot of juice and will generate heat when on for a long while - just make sure they are 100% duty rated. They also incur a rip of EMI on power-off. Make sure you have fly-back diodes on them (1N4001 or better).

Cheers

Todd

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Yes, you do. I run 12, 12v solenoids for my purging/N2 setup. They should be as close to the valve as possible.

Reverse biased, at the solenoid if possible.

Restated: A diode is an electrical check valve... only allows current flow in one direction. Reverse biased means current will not flow through diode when it is powered. Therefore the "arrow" points to the + side of the coil (L) below. R below can be ignored.

Restated: A diode is an electrical check valve... only allows current flow in one direction. Reverse biased means current will not flow through diode when it is powered. Therefore the "arrow" points to the + side of the coil (L) below. R below can be ignored.

Wizard_of_Frobozz

Well-Known Member

Reverse biased, at the solenoid if possible.

Restated: A diode is an electrical check valve... only allows current flow in one direction. Reverse biased means current will not flow through diode when it is powered. Therefore the "arrow" points to the + side of the coil (L) below. R below can be ignored.

How do you go about selecting a diode? In other words, how I make sure I buy the right one?

canmorebrewguy

Well-Known Member

- Joined

- Oct 5, 2015

- Messages

- 103

- Reaction score

- 15

Would it be possible to see a picture of your solenoids and your diodes? If that is not to personal HAHAYes, you do. I run 12, 12v solenoids for my purging/N2 setup. They should be as close to the valve as possible.

directly heating wort with an electric element. add lots of controls so that is not a problem. herms is bad

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

directly heating wort with an electric element. add lots of controls so that is not a problem. herms is bad

Que¡?

How do you go about selecting a diode? In other words, how I make sure I buy the right one?

Basic rectifier diode such as the 1N400x series, where x is 1, 2, 4, 7 (e.g. 1N4007). Can find these anywhere for pennies. Most relay boards have flyback diodes... but basic solenoid valves (the context we are discussing) don't so we need to add them.

Just remember you don't need the pc in the panel per say. Having tested and found the limits of USB, I MUCH prefer Ethernet. For instance I run it on a server, in my equipment room not located by the brewery. Since all my stuff is Ethernet based it acts as basically a "cloud" server.

What limits?

Distance, mostly...

Cheers!

Cheers!

Where would these go in a solenoid valve wiring schematic, I am using solenoid valves for my can filler and wondering if I need these?

Cheers

Todd

Not sure what you guys are doing, but the solenoids and relays don't need the diodes across the coil. That diode is there to protect upstream digital stuff. So, unless the relay is controlled by some digital source, no diode necessary.

Distance, mostly...

Cheers!

Well yea, there's that.

Inductive loads without diodes will induce noise when the drive current is released, so they are necessary, especially for large coils.

Gameface

Well-Known Member

Super simple question, but what's everyone's preferred method for connecting the wires from the electronic valves to the cable that will go to the enclosure? Buttsplice then cover with shrink tubing? Something else?

Similar threads

- Replies

- 45

- Views

- 3K

- Replies

- 29

- Views

- 7K

- Replies

- 51

- Views

- 10K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)