You guys are too good!!

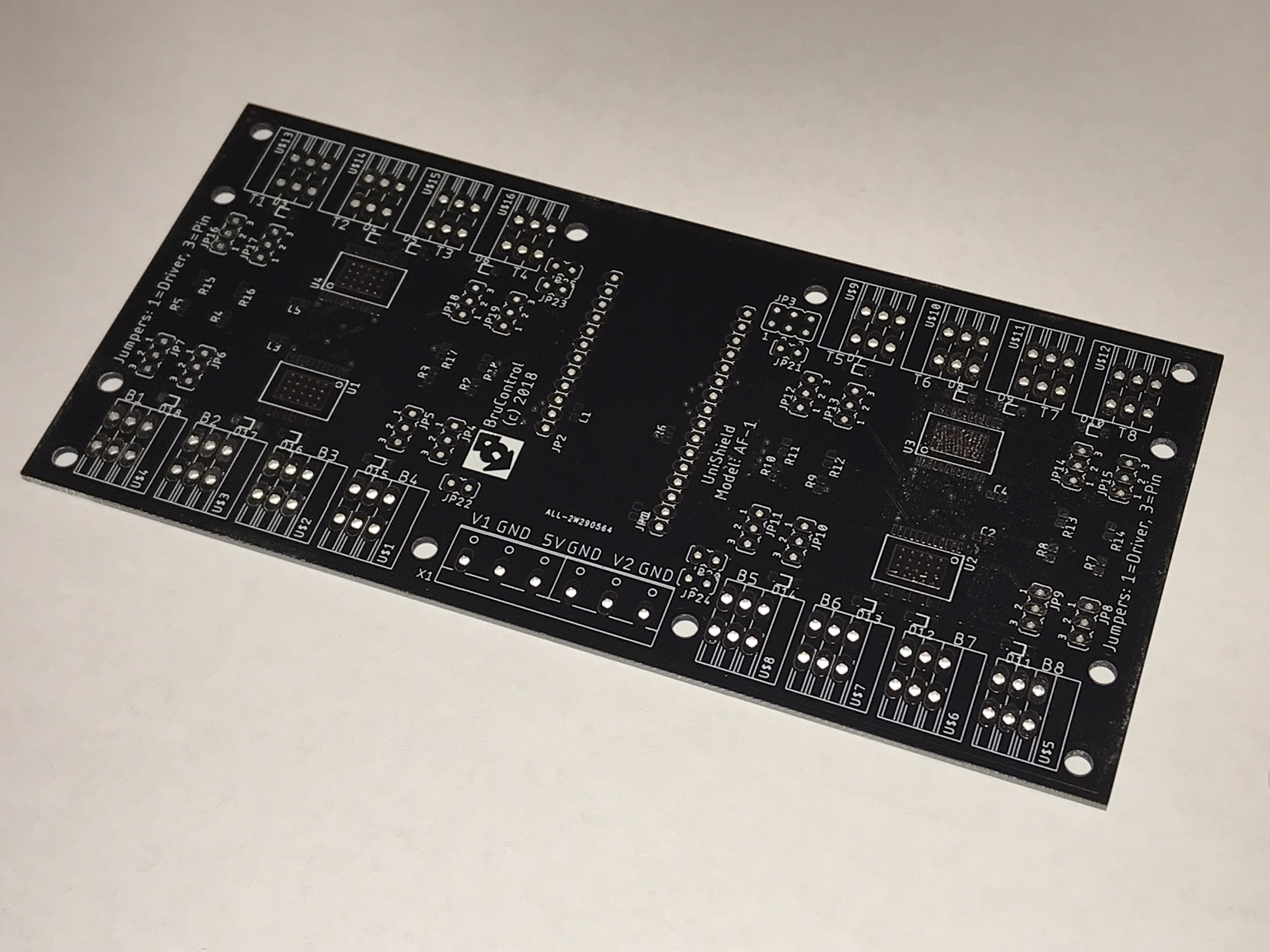

This is indeed a Feather based driver board, allowing for direct connection of relays, pumps, etc. 16 universal I/O channels, up to 5A per channel. Board is split in half so you can drive outputs at two different voltages, ranges 5V to 24V. Each interface pin will have three terminals provided, managed by jumpers: direct (to interface pin, such as for inputs), driven (high current output or PWM), and ground (for easy wiring). This board fits in a DIN rail carrier for easy mounting. It will have an add-on power board to also provide terminals for 5V and higher voltage for easier wiring. The goal of all these terminals is to allow a builder to avoid needing lots of DIN rail terminal blocks.

@passedpawn spotted some key items: yes, the vias are there to distribute heat, B and T are Bottom/Top respectively, and the footprints are spring terminal connectors. The diode is indeed a flyback diode, even though the drivers contain internal ones.

We went with high side (active high design) drivers, not motor drivers. We had plans to use motor drivers, but at the end of the day, you have to decide a default start-up mode, which would have been low, so it didn’t make much sense to use them since active-low devices would be on during start-up (the difference is active-high only versus both active-high and active-low configurable). Motor drivers also take up more space per channel and are twice the price - and when you multiply out the number of I/O we are looking for, it’s a big difference.

We will be soldering a few up then testing them. We’ll offer these but realize that the I/O is limited for bigger control systems. The next iteration will probably be based on the the ESP32, which will provide more I/O. We want to get to MEGA numbers of I/O, so will probably make a MEGA or DUE footprint model. The challenge with these is we want to avoid proprietary microcontrollers, but we would really prefer models with stacking headers instead of the current model which only has female headers on the top side (requires mounting underneath, which we frankly don’t like).

We hope a design like this, while a bit more expensive for parts, will facilitate a smaller enclosure that is much easier to wire. More to come soon!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)