You mean with our firmware, or in general?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

in general testing with various scripts, I've only had this for a week so I'm sure more issues or fixes will happen over time, one nice thing is the firmware is open source and can be altered so that's a plus for you

all great points! rock on! I will look at the ESP32 feather..Hi @clearwaterbrewer... per above, the ESP32 is next.

Yes, the Feather is more expensive, but the platform is reliable and well supported. One consideration: the footprint is baked. The ESP32 has different pinouts and footprint per device, so with the $ savings you get an increased risk that the board you bought doesn't match the format of the last one. Even the "Development" board varies from unit to unit, and we thought if we have to dictate a specific one, then they stop making it, we have just locked you in to a design that is no longer supported. Feather supports add-ons too, so if you wanted to use a basic Feather, then add an Ethernet board... no problem.

Another consideration: you can't (easily) get an external antenna option with ESP32. So if you put it in a metal enclosure, you are kinda screwed. The WROVER based ESP32 has one, but again - the footprints of these are all over the place.

Another consideration... starting small. In designing this, we want to prove a design before going bigger. 16 I/O may not satisfy everyone, but that's OK, we will use this is a simpler and less expensive first step.

We are still testing the ESP32, and have not fully vetted it, so building a board on that adds lots of risk that we get something wrong!

Gameface

Well-Known Member

About how many amps does an automated system draw on the low voltage side?

My current PID based system can draw around 47A when 2 pumps and 2 5500W elements are all going. My GFCI breaker is rated for 50A so I'm worried that the valves in particular might push me right to that limit, although I will really only be moving the valves when the pumps and heating elements are off. I think I read that some of the automatic valves draw power all the time regardless of position or if they are moving?

I can switch my 50A GFCI breaker to a 60A or 63A one, but don't want to if I don't have to.

My current PID based system can draw around 47A when 2 pumps and 2 5500W elements are all going. My GFCI breaker is rated for 50A so I'm worried that the valves in particular might push me right to that limit, although I will really only be moving the valves when the pumps and heating elements are off. I think I read that some of the automatic valves draw power all the time regardless of position or if they are moving?

I can switch my 50A GFCI breaker to a 60A or 63A one, but don't want to if I don't have to.

The valves draw only a handful of watts... they won’t add up significantly.

Chiming in with another newb question. I've plugged in multiple 1-wire sensors to the interface but when I add the devices to the workspace it's only reading from a single temp sensor.

Any thoughts on why this is happening?

Any thoughts on why this is happening?

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

Chiming in with another newb question. I've plugged in multiple 1-wire sensors to the interface but when I add the devices to the workspace it's only reading from a single temp sensor.

Any thoughts on why this is happening?

Figured it out. Even though each sensor is added to a different virtual port, they need to be assigned a unique index number.

Yessir - glad you figured it out.

Next Q. Anyone have problems adding more than three 1-wire temp sensor devices? First three went fine. Added the fourth just like the first three, and it's a no go. Unplugged, re-plugged, tried again, and again no dice.

Edit: confirmed that all sensors are functioning independently.

Edit: confirmed that all sensors are functioning independently.

Last edited:

have you added the resister ?

Yeshave you added the resister ?

Have you proven the fourth probe could work as one of three yet?

Cheers!

Cheers!

What is the value of the resistor (check it with a meter). What is the input voltage to the sensors (also check with a meter) and how are these powered? More system details will help us debug with you.

Input voltage is 5v, powered from the Arduino. Verified the voltage with a meter yesterday.What is the value of the resistor (check it with a meter). What is the input voltage to the sensors (also check with a meter) and how are these powered? More system details will help us debug with you.

Might be a few days before I can get back to the project. When I do I'll check the resistor.

Last edited:

Found a picture of the resistor. Looks like it's a red/red/red/gold, 2.2k Ohms. Looking at the wiring diagram on the website, which recommends 4.7k Ohms, I'm guessing this is the issue.

Last edited:

As I run 2.2K on a five probe setup that's not likely the problem.

Check that the added probe works with just two others first...

Cheers!

Check that the added probe works with just two others first...

Cheers!

Try the resistor. Don't just look at it... read the actual value with a VOM.

HobbyBrauer

Active Member

How is everyone wiring their relay board? I have the recommended 8-channel DIN mountable one from the order list with 24v coils. My issue is that all the devices controlled by it use 24vDC power so I have all the commons on the relay channels daisy chained and the first linked to the 24vDC bus. While this works all the loops cause a lot of clutter and I was wondering if everyone is doing the same or if not what? Is there a board out there that will power the relay off 24v and link the relay commons to the same 24v so there would only be a NO and NC terminal for each relay channel?

Daisy chaining not such a good idea for more than 2 or three channels... agreed though a single common would be nice.

HobbyBrauer

Active Member

Daisy chaining not such a good idea for more than 2 or three channels... agreed though a single common would be nice.

Yeah I was noticing the same thing. Huge voltage drop on channels 6-8 and I'm using the largest wire gauge possible with the terminal blocks.

So I'm assuming you haven't come across a board with a single common? If so, what is my best option here? Maybe a ring circuit with channels 1 and 8 connected to 24vDC bus and then daisy chain the others? Alternately, I could desolder/remove the common terminal blocks and solder in a solid copper wire which connects with the VCC terminal block on the board.

Gameface

Well-Known Member

Can you show a pic? I assumed, at least with the board I have, I wire 24V to the VCC terminal from the 24V power supply (or a 24V bus). Is that not how these things work? You have to wire 24V from the power supply (..bus) to each com terminal? That doesn't seem right to me.

I'll take a pic of my relay board tomorrow with some info on how I believe it is supposed to be wired. This is something I hope to be doing in the next week or two.

I'll take a pic of my relay board tomorrow with some info on how I believe it is supposed to be wired. This is something I hope to be doing in the next week or two.

HobbyBrauer

Active Member

Here’s a pic. My question is instead of running all of these loops from COM to COM is there a better way?

Wizard_of_Frobozz

Well-Known Member

How about this: https://www.amazon.com/dp/B01FCWEYEI/?tag=skimlinks_replacement-20

Takes up a lot of additional space in the panel but it's a single common to up to 10 loads, each with a standard automotive style blade fuse and blow indicator LED. Wire those to the relay board.

Smaller option without the fuses: https://www.amazon.com/dp/B01CU62WPM/?tag=skimlinks_replacement-20

Another option would be terminal blocks with jumpers to create your own common distribution and wire each relay from it. That's how I've typically seen it done in industrial panels with a single power supply and multiple relays.

Takes up a lot of additional space in the panel but it's a single common to up to 10 loads, each with a standard automotive style blade fuse and blow indicator LED. Wire those to the relay board.

Smaller option without the fuses: https://www.amazon.com/dp/B01CU62WPM/?tag=skimlinks_replacement-20

Another option would be terminal blocks with jumpers to create your own common distribution and wire each relay from it. That's how I've typically seen it done in industrial panels with a single power supply and multiple relays.

Last edited:

Gameface

Well-Known Member

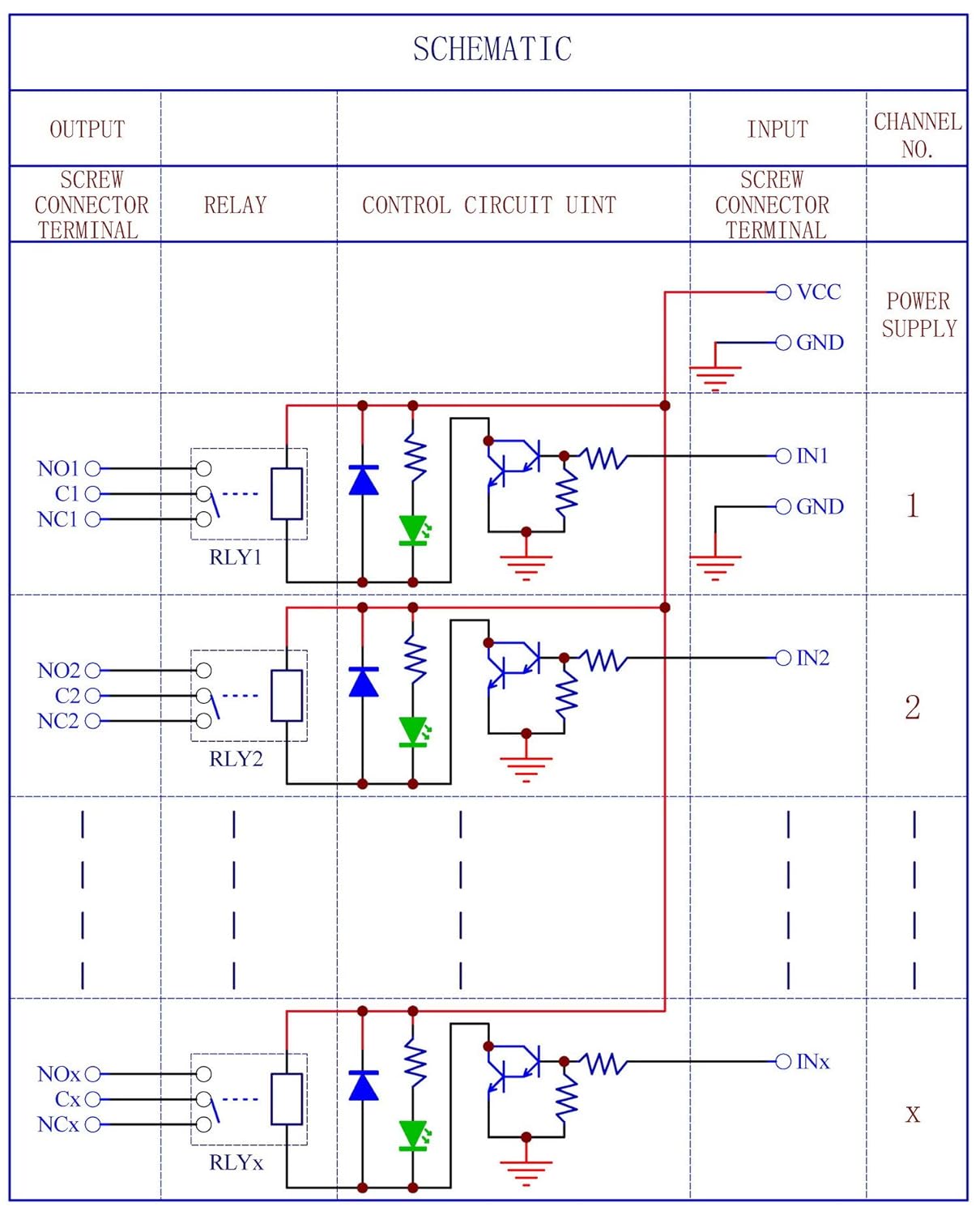

I think this is the schematic, my board is similar

I guess I misunderstood the wiring. So I'm going to need to wire +24 to each of the C1, C2... terminals?

I guess I misunderstood the wiring. So I'm going to need to wire +24 to each of the C1, C2... terminals?

Wizard_of_Frobozz

Well-Known Member

I guess I misunderstood the wiring. So I'm going to need to wire +24 to each of the C1, C2... terminals?

That's correct, assuming that the only devices you are trying to control on the relay board are all 24V powered devices.

The VCC is just to power the relays (i.e. make the relay itself move). It's an electromagnet that moves the switch from Cx to either NOx or NOx; that electromagnet gets it's power from VCC but it's completely independent of the load the relay is switching.

The reason these boards don't have a single common is that it allows you to drive different types of devices off the same board. You can start/stop an 120 V AC pump on one, a motorized 24 DC valve off another, a 12V DC solenoid on another, and so on. If there were a single common, you'd be locked into having only one type of voltage device to control.

Gameface

Well-Known Member

I assumed I was restricted to 24v outputs. Good to know. But can I actually switch ac as well? Like my ac pumps?That's correct, assuming that the only devices you are trying to control on the relay board are all 24V powered devices.

The VCC is just to power the relays (i.e. make the relay itself move). It's an electromagnet that moves the switch from Cx to either NOx or NOx; that electromagnet gets it's power from VCC but it's completely independent of the load the relay is switching.

The reason these boards don't have a single common is that it allows you to drive different types of devices off the same board. You can start/stop an 120 V AC pump on one, a motorized 24 DC valve off another, a 12V DC solenoid on another, and so on. If there were a single common, you'd be locked into having only one type of voltage device to control.

Wizard_of_Frobozz

Well-Known Member

I assumed I was restricted to 24v outputs. Good to know. But can I actually switch ac as well? Like my ac pumps?

Sure can! Each relay's switching side is 100% isolated from any other source. No issue at all with this type of relay board to have each one switching a different type of load (just make sure you're wiring the correct relay to the correct load!)

I've got a 5vdc powered relay board in my panel that switches my pumps on and off (120 vac). Works with no issue.

You do need to pay attention to the maximum ratings of the relays - in this case, I believe that's 10 amps, so don't go trying to switch your heating elements with them!

EDIT: From the Amazon listing: Contact Rating: 125VAC/250VAC 10Amp or 30VDC 5Amp.

Gameface

Well-Known Member

That's awesome.Sure can! Each relay's switching side is 100% isolated from any other source. No issue at all with this type of relay board to have each one switching a different type of load (just make sure you're wiring the correct relay to the correct load!)

I've got a 5vdc powered relay board in my panel that switches my pumps on and off (120 vac). Works with no issue.

You do need to pay attention to the maximum ratings of the relays - in this case, I believe that's 10 amps, so don't go trying to switch your heating elements with them!

EDIT: From the Amazon listing: Contact Rating: 125VAC/250VAC 10Amp or 30VDC 5Amp.

Hi,

FYI we uploaded an application note to the website which demonstrates how to build a simple fermentation controller for BruControl, using an off-the-shelf wireless switch, for under $50 (assuming you have most of the tools). This unit is dual-channel, so it can be used to heat & cool a fermentation chamber, run two refrigerators for fermentation & dispensing, run a glycol pump and ball valve for conicals, or do whatever you want with two 120V supplies: http://brucontrol.com/build/resources/

I bought to of the SonOff Duals (until the S31's get working) and have them added to my workspace and both relays work, but the 1-wire probe I have on each one is not reading, I just see the '----' I am using port 200 and index 0. firmware v.43 I have working 1-wire sensors on 2 mega's and a feather M0...

any thoughts?

edit - fixed, bad solder joint hiding....

Last edited:

Good stuff!

Fairly frustrating that the notification system of the forum is not working or really slow to respond!

Fairly frustrating that the notification system of the forum is not working or really slow to respond!

I agree I mentioned this to 2 admins before and then the emails were sent out no earlier than 4:30 pm central now it's 2:30 but still not as fast as it should be

Gameface

Well-Known Member

I agree I mentioned this to 2 admins before and then the emails were sent out no earlier than 4:30 pm central now it's 2:30 but still not as fast as it should be

I used to get notifications on my phone via the app but now... crickets.

@BrunDog

I know I read about wiring on the proportional valves before, and from what I remember you do not wire the feedback signal wire up on yours? My concern is being able to use the 3-wire XLR connectors.

I don’t use feedback and trust running in open loop mode. That only requires 3 wires: power and signal.

Wizard_of_Frobozz

Well-Known Member

While we're on the subject of the proportional valves, what is the purpose of the analog amplifier board (AA-1) that you offer? http://brucontrol.com/wp-content/uploads/2018/05/AA-1C.jpg

From what I understand, the proportional valve control signal is 0-5V; doesn't the analog pin on the Arduino produce that? Why can't I just connect the analog pin directly to the valve? Got a schematic that shows how the analog amplifier board gets wired up?

Also, the links to the valve specification sheets aren't working on this page: https://brucontrol.com/buy/valves/

From what I understand, the proportional valve control signal is 0-5V; doesn't the analog pin on the Arduino produce that? Why can't I just connect the analog pin directly to the valve? Got a schematic that shows how the analog amplifier board gets wired up?

Also, the links to the valve specification sheets aren't working on this page: https://brucontrol.com/buy/valves/

Last edited:

Arduino's and other micro interfaces typically do not have Analog Out ports (some do, but limited). They have PWM (Pulse Width Modulation) out ports, which is a high frequency, single voltage output. The output voltage is either zero or full, but variation in the output is the percentage of time the output is on. 50% is on for half the cycle and off for the other half. This is like Duty Cycle, but very fast at ~1000 cycles per second.

To convert that PWM signal to analog, a simple Resistor-Capacitor circuit (low pass filter) can be used. The challenge with this is if a proportional valve (or other proportional device like an SSR) requires a bit of current to drive its input signal, the interface PWM output pin and RC circuit combination may not allow it. I have successfully run devices doing this, but using an intermediate board adds safety and likely better control. The AA board converts the PWM signal to analog, then amplifies it to whatever range you need in a proportional signal (for example, 0-10V).

The schematic is fairly straightforward... but we should post up a schematic. I'll do so along with the spec sheet fix - thanks for noting it.

To convert that PWM signal to analog, a simple Resistor-Capacitor circuit (low pass filter) can be used. The challenge with this is if a proportional valve (or other proportional device like an SSR) requires a bit of current to drive its input signal, the interface PWM output pin and RC circuit combination may not allow it. I have successfully run devices doing this, but using an intermediate board adds safety and likely better control. The AA board converts the PWM signal to analog, then amplifies it to whatever range you need in a proportional signal (for example, 0-10V).

The schematic is fairly straightforward... but we should post up a schematic. I'll do so along with the spec sheet fix - thanks for noting it.

Wizard_of_Frobozz

Well-Known Member

Arduino's and other micro interfaces typically do not have Analog Out ports (some do, but limited). They have PWM (Pulse Width Modulation) out ports, which is a high frequency, single voltage output. The output voltage is either zero or full, but variation in the output is the percentage of time the output is on. 50% is on for half the cycle and off for the other half. This is like Duty Cycle, but very fast at ~1000 cycles per second.

To convert that PWM signal to analog, a simple Resistor-Capacitor circuit (low pass filter) can be used. The challenge with this is if a proportional valve (or other proportional device like an SSR) requires a bit of current to drive its input signal, the interface PWM output pin and RC circuit combination may not allow it. I have successfully run devices doing this, but using an intermediate board adds safety and likely better control. The AA board converts the PWM signal to analog, then amplifies it to whatever range you need in a proportional signal (for example, 0-10V).

The schematic is fairly straightforward... but we should post up a schematic. I'll do so along with the spec sheet fix - thanks for noting it.

That all makes sense. Thanks - now I know I have to leave enough space in the panel for the 24 vdc power supply and the AA board; what are the dimensions of that board? It would be helpful if you posted the physical dimensions of all your products on the site so I wouldn't have to keep bugging you with lots of these questions!

Solid point! It is 70mm (2.76") wide x 72mm (2.83") high.

What is the best way to get a Tilt working with BruControl. I have a Feather M0 and a couple ESP32's in the bags still, will either of these work? The last thing I saw was using a Primo...

The ESP32 will work... once we issue v1.1!

Similar threads

- Replies

- 45

- Views

- 3K

- Replies

- 29

- Views

- 7K

- Replies

- 51

- Views

- 10K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)