I know folks around here have tended to stay away from using mass as a means to measure volume but in my area (biopharmaceutical manufacturing), mass is the gold standard if you want to know the volume of a liquid. This is especially true in fixed/permanent tank installations where mass information is feed into a DCS historian every ~5 seconds 24/7/365. Where hygienic design is paramount, any extra wetted components are frowned upon. Granted that level of cleanliness is not as important in brewing but to be considered none the less. Following on work done by

@paledragon I went with load cells, two Uno's w/lcd displays, HX711, and MCP4725 DACs to measure the mass of my boil kettle and MLT for my two vessel RIMS setup. I know drift (it is actually characterized as "creep") is often cited as a concern but I have not seen that to be a problem and I have found readings to be more cyclical (when looking at days of data) where the values will go down and up not just down, down, down. I attribute that to changes in room temperature but it is a tiny amount (0.038 kg max so far). While I do not intend to use the mass cells for long term measurement, I see no evidence that it couldn't. I am also using a one wire temp sensor to provide temp info from the load cell installation location and using that to provide "temp comp" for the load cells if/when they get outside the designed "already temp compensated" range for the load cells. I was going to deploy some time based compensation for creep and while I may still do that, I have not found that I need to at the moment.

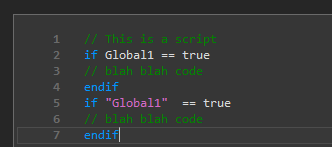

Especially with the advent of the lookup table function in the BC RC, calibrating the analog output from the MCP4725 has made the mass (I convert to volume in the BC element) to be very accurate throughout the entire measurement range even if the input (DAC output) is not exactly linear. Creep appears to be insignificant in the context of how I plan to deploy it.

Sure it would be great to perhaps integrate this into a controller connected to BC directly and perhaps someday that will be possible. Considering the low cost of these controllers and how I wanted a local display with local tare functionality from that local UI, the separate controllers, lcd displays, and feeding an analog output to the BC controller via the 12-bit MCP4725 DAC works really well. That kind of detail would not be easy within the confines of a BC element for example nor would driving a local display to show the units I want, etc.. Don't be afraid to use mass is what I would say and also don't use super cheap load cells from a bathroom scale that lacks any specifications. The 50 kg units from Phidgets for less than $10 a piece look to be good units. A beauty of BC is the flexibility to do it your way!

This is what my scale enclosure for two vessels looks like. Also note you could do this with one controller but I wanted two displays showing the same data at the same time for both load cell setups.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)