exoticatom

Well-Known Member

v46B mega issues..

I upgraded (read try) to upgrade Arduino Mega from 45O to 46B_W as I am using WiFi shield.

I followed to the best of my abilities the procedure as in the previous posts.

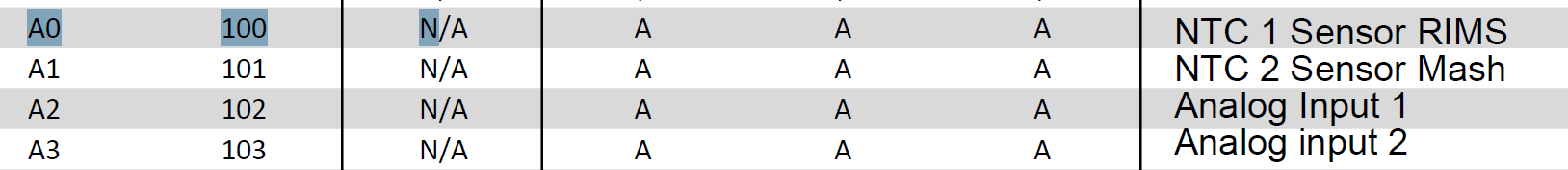

1) changed wiring map element in XML; CFG,

2) upgraded mega to FW to v46B_W. without issues.

3) upgraded PC SW.

4) deleted and created new elements, but none of the new elements work.

Arduino is making the connection, that seems to be working. Nonanalog inputs and outputs are working.

But I can't make analog inputs OK.

Tested setup is:

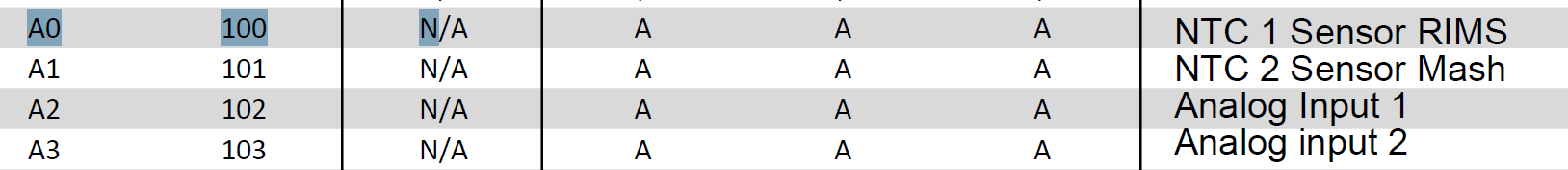

NTC1 -> A0 old 100, new 54

NTC2 -> A1 old 100, new 55

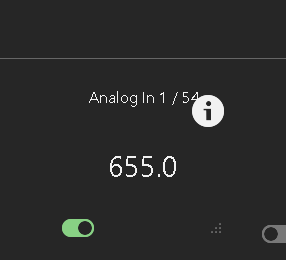

old:

new:

new element:

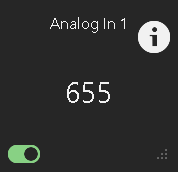

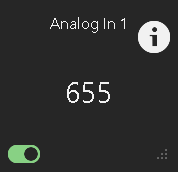

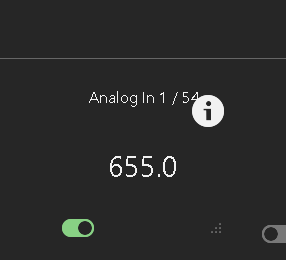

but it's stuck into 655 value.

I had thermistor NTC10k connected to A0 -> 100, and created an Analog Input Element with 54. But the number on the element, where it should be temperature is not changing, it is stuck.

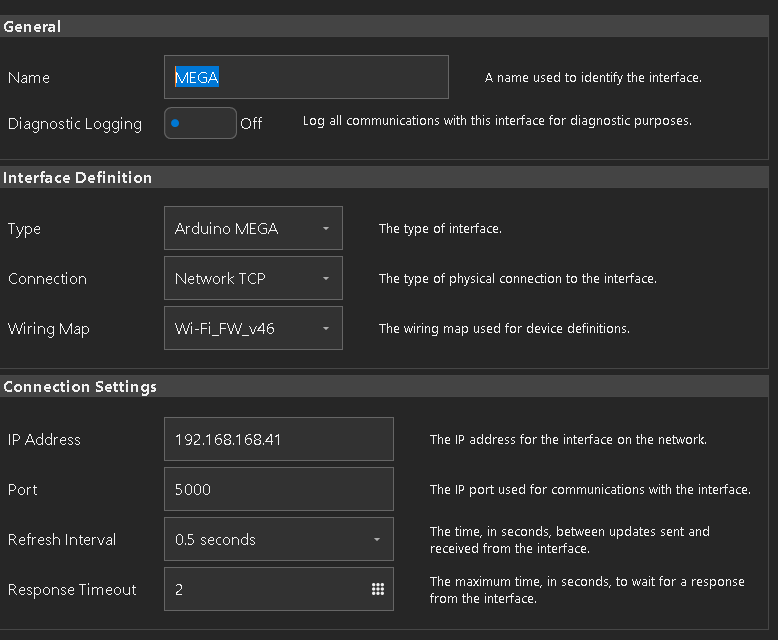

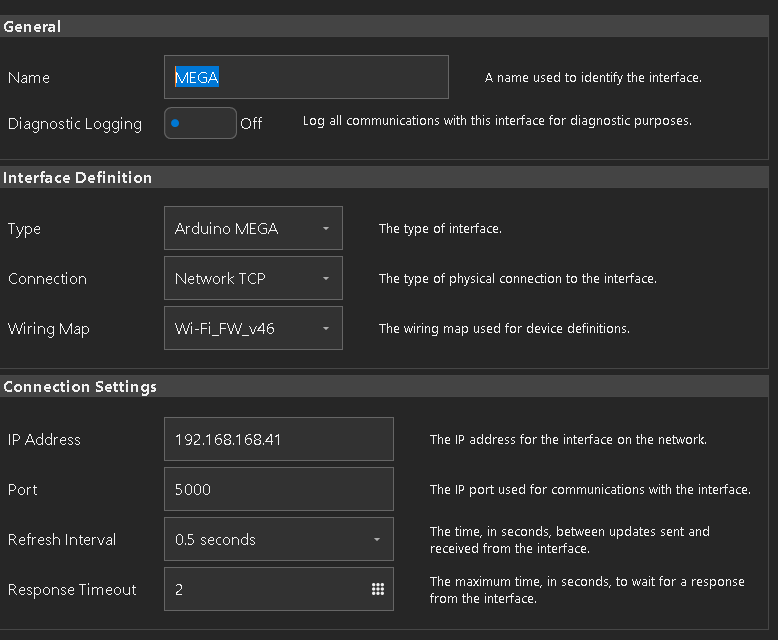

mega setup:

tried several inputs, but all are fixed, and I have NTCs connected to A0 and A1

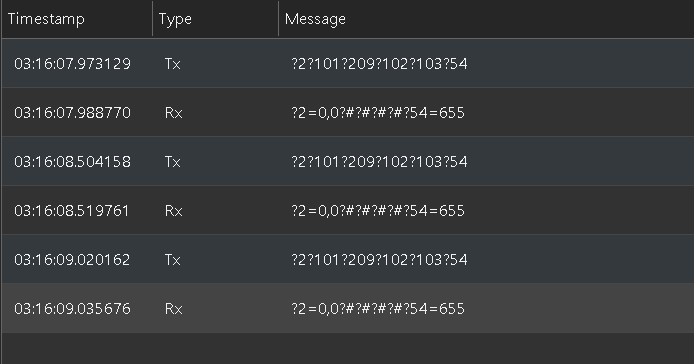

I just enabled port54:

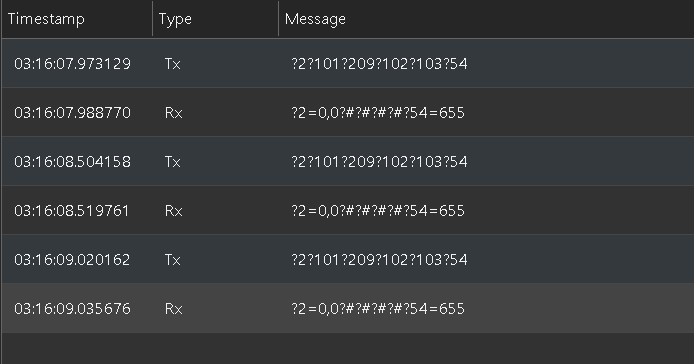

communication:

If I revert everything, FW; Software all works fine.

Any idea where to go with troubleshooting?

I upgraded (read try) to upgrade Arduino Mega from 45O to 46B_W as I am using WiFi shield.

I followed to the best of my abilities the procedure as in the previous posts.

1) changed wiring map element in XML; CFG,

2) upgraded mega to FW to v46B_W. without issues.

3) upgraded PC SW.

4) deleted and created new elements, but none of the new elements work.

Arduino is making the connection, that seems to be working. Nonanalog inputs and outputs are working.

But I can't make analog inputs OK.

Tested setup is:

NTC1 -> A0 old 100, new 54

NTC2 -> A1 old 100, new 55

old:

new:

new element:

but it's stuck into 655 value.

I had thermistor NTC10k connected to A0 -> 100, and created an Analog Input Element with 54. But the number on the element, where it should be temperature is not changing, it is stuck.

mega setup:

tried several inputs, but all are fixed, and I have NTCs connected to A0 and A1

I just enabled port54:

communication:

If I revert everything, FW; Software all works fine.

Any idea where to go with troubleshooting?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)