- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Good question. I didn’t see it either. I turned my phone to the side and boom there it was. I’m sure tablet users were fine though.Where the heck is the post number on mobile version of website?

Good question. I didn’t see it either. I turned my phone to the side and boom there it was. I’m sure tablet users were fine though.Where the heck is the post number on mobile version of website?

Where the heck is the post number on mobile version of website?

That did the trick!Good question. I didn’t see it either. I turned my phone to the side and boom there it was. I’m sure tablet users were fine though.

I visited the posts you mentioned. What exactly is the “power boost”?Sorry can't help you there, I'm not familiar with the mobile version. Guess I'm old school and use the PC version only.

I visited the posts you mentioned. What exactly is the “power boost”?

This guy? https://learn.adafruit.com/adafruit-powerboost-500-shield-rechargeable-battery-packThat part is essentially a rapid charger for lithium batteries that provide backup power to the MEGA in case of a power blip or outage.

This guy? https://learn.adafruit.com/adafruit-powerboost-500-shield-rechargeable-battery-pack i seethe benefit of having power during the blip but what’s the benefit during an outage? Won’t everything else be de energized and the Mega running by itself?

I have the immediate option to bring 5v to supply Mega. Would this be better than the current 12v?

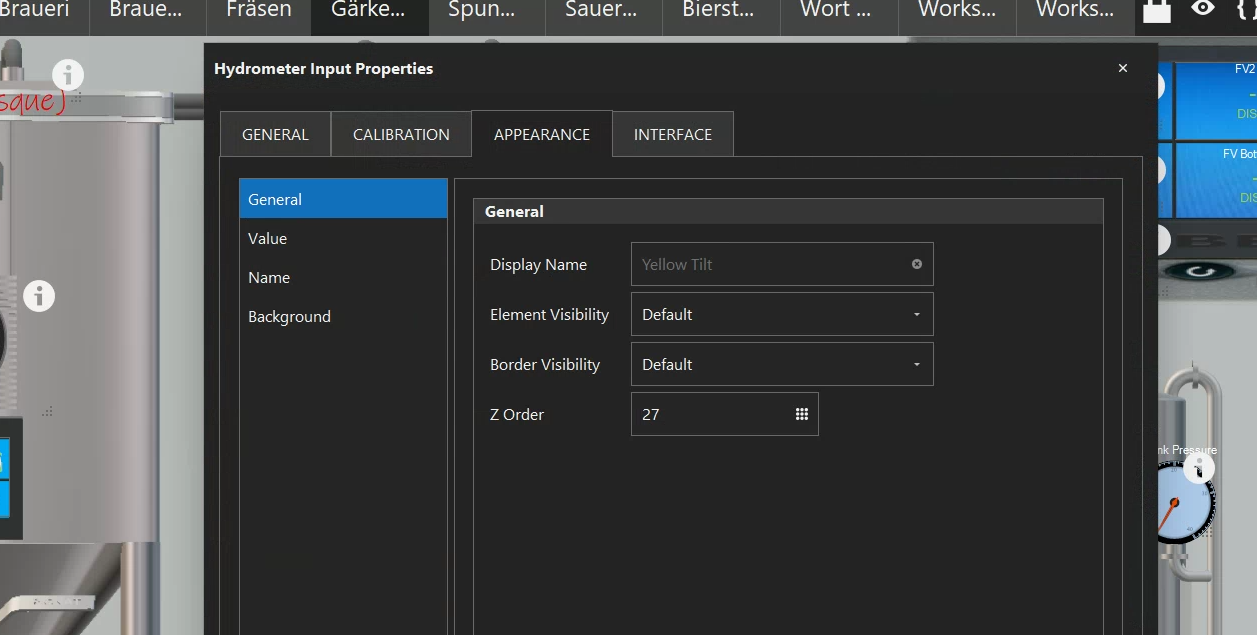

New version with Alias?

It’s a Unitronics V350A lot is going to depend on what PLC you are using? I work with AB/Rockwell gear... I wish I could get a transmitter for $100. Typically you add a 0 and start there

What do you mean by eliminate the battery? I thought this is required to provide the power in the event of an outage? Are you saying this board is an option (without battery) to help regulate the power to Mega?Eliminate the battery backup and its a direct connect Micro USB from the power supply into the MEGA.

What do you mean by eliminate the battery? I thought this is required to provide the power in the event of an outage? Are you saying this board is an option (without battery) to help regulate the power to Mega?

I have the power booster, switch and battery on order. Can someone help with the question above? Curious the best way to provide power to the power booster and if I can use the existing 24v to 5v step downIn place of the wall wort you linked, can I hard wire the supply end of a micro usb cable to a 5v power supply? Otherwise ill have to install an AC receptacle in my panel (which i have)

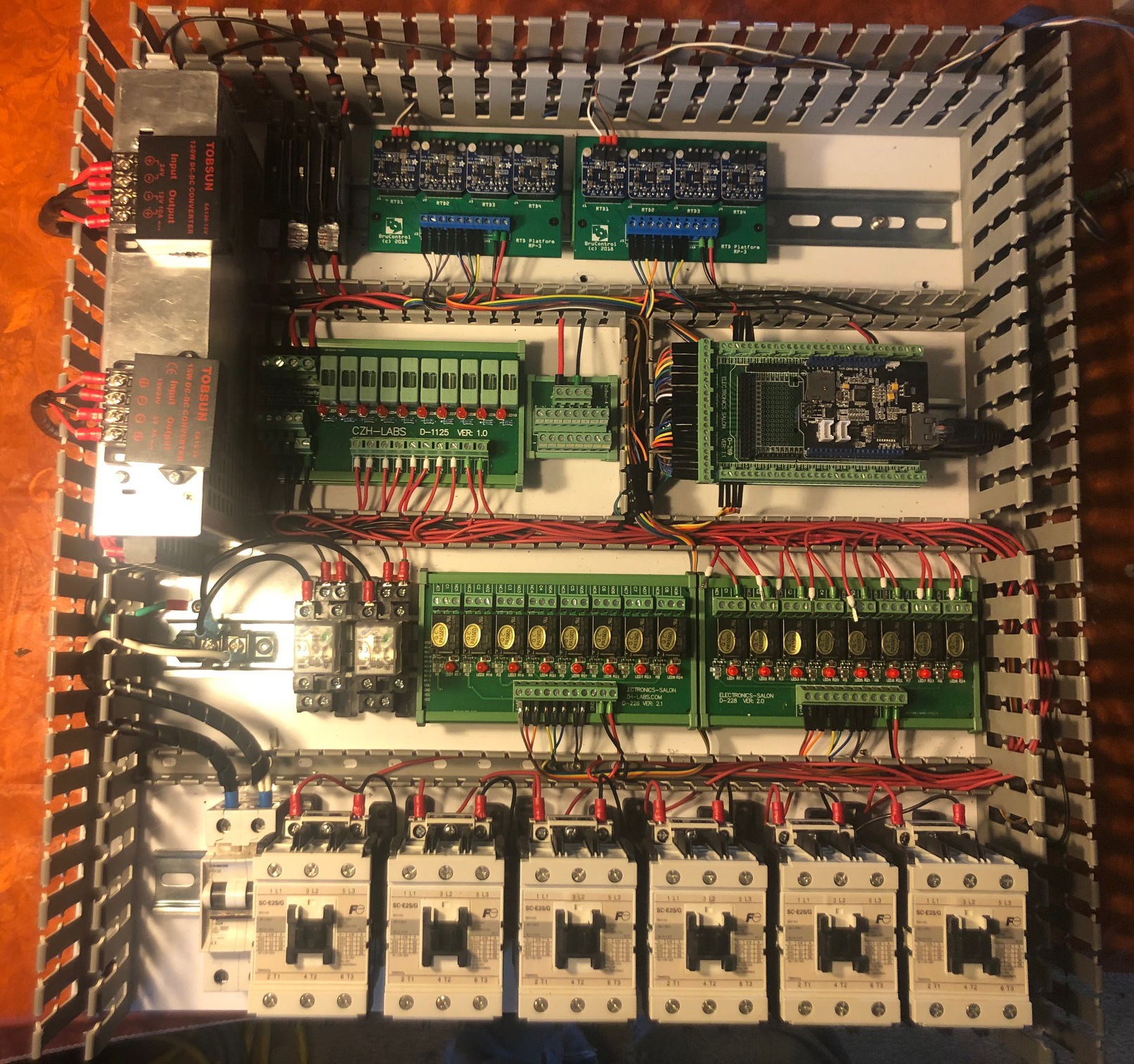

The power supply I have is below. This same power supply also brings 5v to (3) rp-3 boards.

https://www.amazon.com/BINZET-Converter-Regulator-Regulated-Transformer/dp/B00J3MHRNO/ref=sr_1_3?dchild=1&keywords=24v+to+5v+step+down+transformer&qid=1585850475&sr=View attachment 673890

I want to be sensitive to what is going on in our world right now... with almost every one of us affected individually and economically by COVID. So please understand my UniShield post, and this one, aren't meant to assume we are free to spend money perhaps like we did a few weeks ago. I looking forward to recovery so we get on with life! In the meantime, for those spending more time at home, I hope you are making more beer!!

Here is a new SBC (Single Board Computer) that just hit the market. Pretty good looking board at $218, with a 8GB of memory, 64B of storage, a Celeron processor, AND it has an Arduino/BruControl compatible microcontroller and header ON BOARD! You could build a single board solution in a control box if you wanted. We'll source one and test it at some point!

Link: https://www.seeedstudio.com/ODYSSEY-X86J4105800-p-4445.html

Can you provide a link to the 9kw 3 phase elements?I have 5(soon to be 6) 9kw dernord 2" Tri-Clamp 3-phase heating elements, and run them in 2 pairs and a single... I am doing distilling, not boil-kettle, but it is still boiling, so I have them cycle down at temps, bot the liquid and the vapor temp above (and it is a Bain-marie kettle, not direct element, so I monitor the boiler jacket temp and pressure also)

coming from BCS, I ran it like that, with different 'states', and exit conditions for the state, and a variable displaying the 'state' name on the screen...

Then take the one PID output from the arduino and branch that out to the common terminal on 3 of the relays. Take the NO output from these 3 relays and feed that to the input of your high voltage/power SSR/relays that you are using to switch the 3 different heating elements. Then you turn the 3 different outputs on/off depending on how much power you want at that time.

This implementation may be overkill. In reality, you may find that hooking 2 elements up to just be on/off and the third to be set for PID might work well. When heating you would have all 3 on all the time, until you reached your target or an offset below the target. Then you could switch to only having one element on and in PID mode to maintain temperature. As long as you can maintain temperature with one element then this would probably be the easiest implementation and would eliminate the need for the 4 channel relay board above.

I had a feeling my interpretation of what @crane is suggesting is either wrong or crane doesnt understand the components (specifically the contactors) I have.I'm not inspecting that conversation closely... but: 1. 5V will not drive a 24V device directly, and 2. the MEGA certainly cannot deliver enough current to drive a coil (any coil) directly.

Always make sure that any device driven by an interface output does not exceed its microcontroller limit(s). For the MEGA, you should keep it to under 15mA per pin (that's 0.015A - basically nothing). You always need a solid state front-end to switch low current into high current (example: solid state relay / transistor / etc.). For example, the relay boards we often use have this intermediate front-end circuitry built in. This is why we made the UniShields - to eliminate this headache.

My last post on the topic has a schematic attached for the proposed change. I know the configuration from the relays to the contactors work I was trying to improve my design based on @crane suggestion. This required wiring changes which I was in the middle of verifying in my last few posts (hence why they are disconnected).You can use a single binary type output (whether it be a PID, duty cycle, whatever) to drive as many elements as you want. Just need to make sure that each chain in the link is strong enough not to break. It looks like from your picture (can't say for certain without a matching schematic) you have the MEGA outputs going to the relay boards. This is good - they have transistor front ends. From there, those relays can switch power to the contactors. Not sure why you disconnected the relays?

I know I sound like a broken record, but what the heck... you should always draft up a schematic to go with your physical wiring. This way the design can be validated first.

I had a feeling my interpretation of what @crane is suggesting is either wrong or crane doesnt understand the components (specifically the contactors) I have.

My end goal is to use a single PID to drive (3) elements. Each element will have a switch via digital out that allows for separate on/off control either manual or script. This same scenario will occur in HLT and Kettle hence why I have (6) contactors.

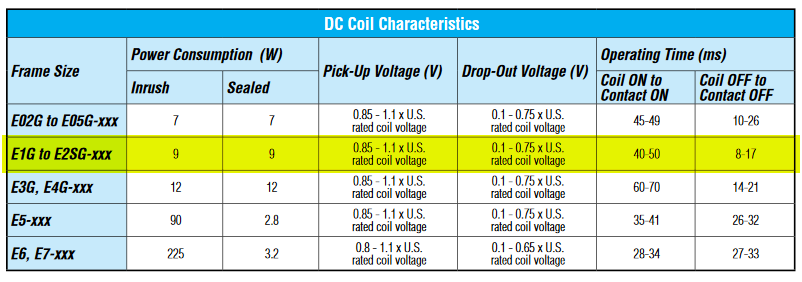

Yes, I have considered the electric noise. I have planned on using snubbers across the coils to help with noise as well. I dont have much experience with PID and was hoping there was some setting or something to reduce the on/off cycling. Perhaps a hysteresis would be better with the components I have?I'm not familiar with the contactor type you are using but are they the traditional magnetic contact coil type or more solid state like an SSR? Reason I ask is have you considered the electrical noise created when a traditional magnetic coil contactor engages and releases high voltage? I had numerous disconnects of my MEGA when switching from my HLT to Boil elements and had to install snubbers across the coils to subdue the electromagnetic noise created upon disconnect. Also if these are magnetic type contact coils you could end up shortening the life of the coil contacts with all the on/off cycling of the PID driving them.

I think you would be better off having your relay setup drive the 24VDC coil on the contactor ON/OFF and then have the PID drive an SSR control input which then controls the high voltage (240VAC) from the contactor thru the SSR.

I am controlling three elements for one control circuit. Are you saying to incorporate three contactors for ON/OFF and three SSRs for high voltage>?

I currently have each contactor wired to relays and I dont see any issues when I fire the contactors via digital out. Tho I do not have a load on these, not sure it matters cuz I think its the coil side that causes EMI correct? Mega stays on and PT100 readings are stable.Contactor coil ON/OFF thru a relay ( this limits the on/off cycles of the coil + noise) and PID control the input control side of the SSR's for your high voltage from the contactors. Basically you could energize (HLT+Boil)1-6 contactors using script or manual thru relays switching the Common 24VDC to the coils and drive how many elements you want active through a common PID's driving the SSR HLT and Boil.

I currently have each contactor wired to relays and I dont see any issues when I fire the contactors via digital out. Tho I do not have a load on these, not sure it matters cuz I think its the coil side that causes EMI correct? Mega stays on and PT100 readings are stable.

Im stuck on the SSR recommendation. I understand using the PID with SSR as control circuit but are you saying one SSR per HLT and one SSR per kettle or one SSR per contactor? I am planning on 12kw 3phase elements which is why i went with contactors to begin with.