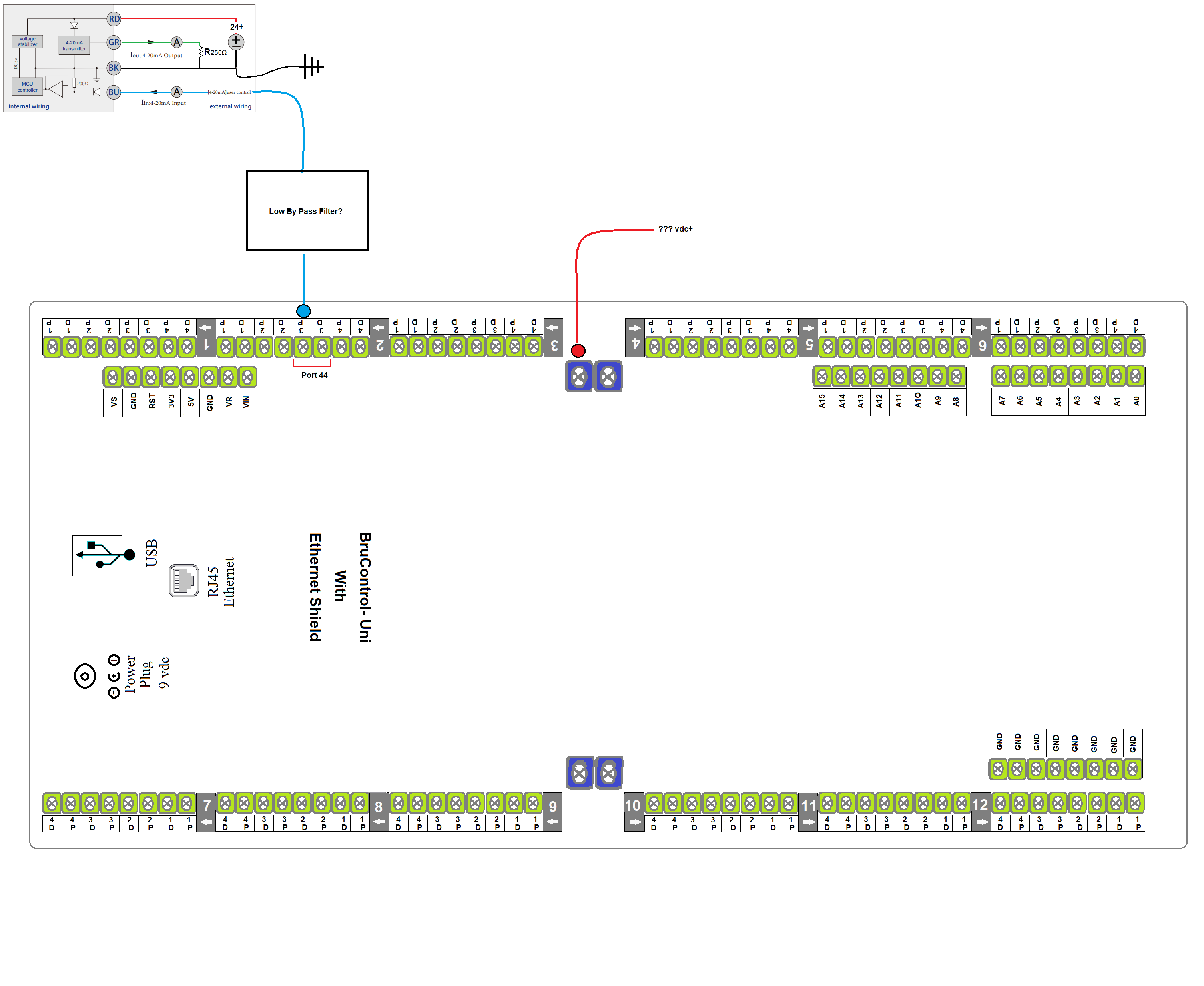

Generally, I intend to use the UNI to drive Valves. I can see the real potential for this being the "BruControl" Primary Interface.

My next question deals with P and D switch. I assume that you would normally only use one or the other (P or D). For Valves, You would want to use the "D" Screw Terminal with the appropriate Power connected to the Bank. You would use the "P" Screw Terminal to drive an external SSR or Proportional Controller. Also if you use the Port as other than a Digital Output Type (Digital Input/Counter/One Wire/SPI etc).

Could you give me an example of why you would want it off? Can it be a "general statement" that when using the "P" Screw Terminal, you would normally have the Switch to Off?

and lastly, since you are only wiring to only one Terminal (P or D) , is there a "need" to mess with the switch?

Since this also seems to be a great One Wire board, I will be using Port 5 (Screw Terminal 9-2P) for that. Is that a reason to have the D P Switch off?

My next question deals with P and D switch. I assume that you would normally only use one or the other (P or D). For Valves, You would want to use the "D" Screw Terminal with the appropriate Power connected to the Bank. You would use the "P" Screw Terminal to drive an external SSR or Proportional Controller. Also if you use the Port as other than a Digital Output Type (Digital Input/Counter/One Wire/SPI etc).

Could you give me an example of why you would want it off? Can it be a "general statement" that when using the "P" Screw Terminal, you would normally have the Switch to Off?

and lastly, since you are only wiring to only one Terminal (P or D) , is there a "need" to mess with the switch?

Since this also seems to be a great One Wire board, I will be using Port 5 (Screw Terminal 9-2P) for that. Is that a reason to have the D P Switch off?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)