HarkinBanks

Well-Known Member

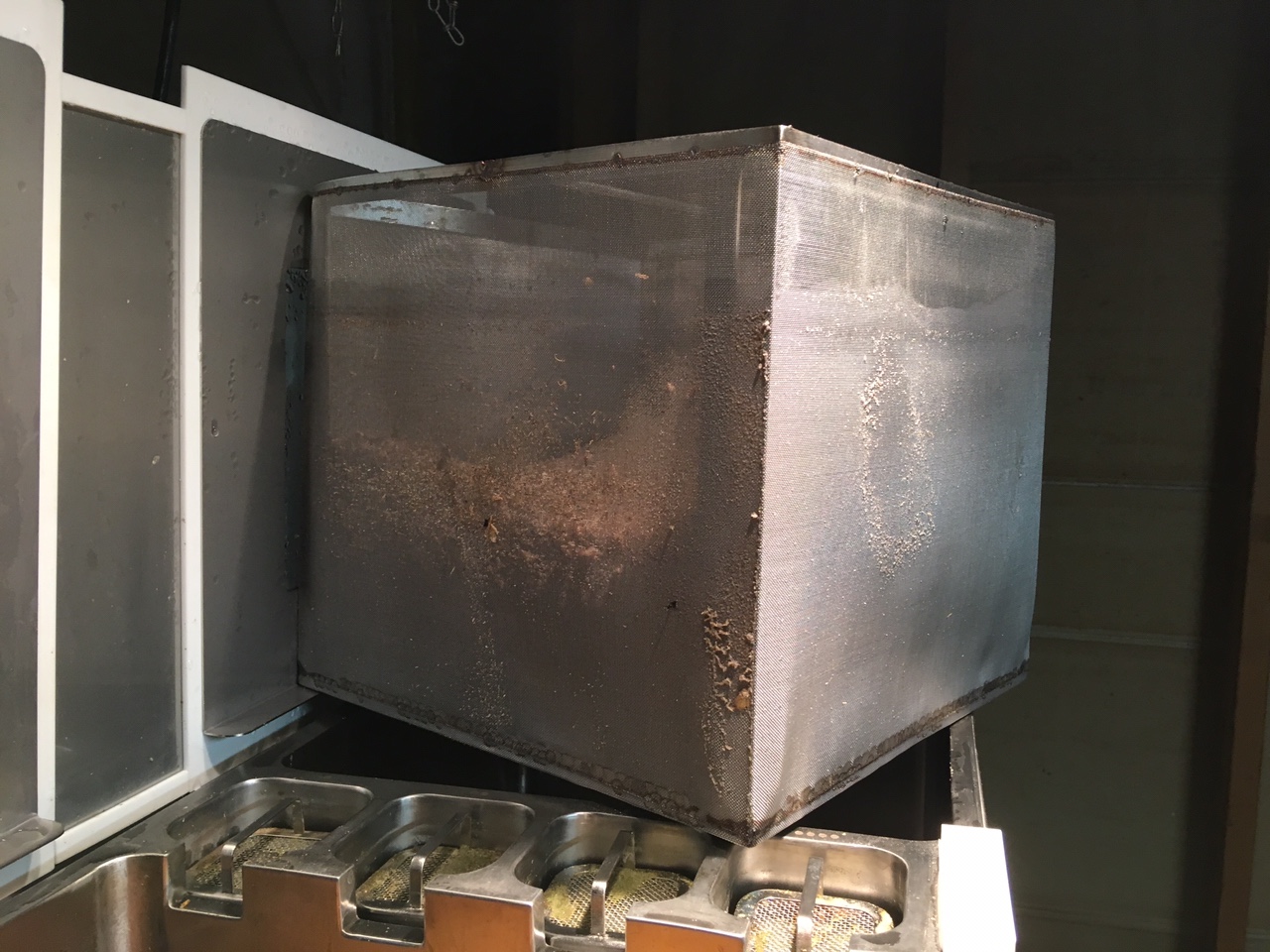

Well same story on the mash tun side. One of my connectors was being fried. I replaced all of them and insulated with silicone tape. Glad I caught this before it became any worse. I scraped off all of the epoxy. I would recommend doing both sides to everyone.

Design is exactly the same as the boil element and is easier to access. Four nuts, unclip the drain tube and wires, unclip the switch on the side and lift up.

Pics

Design is exactly the same as the boil element and is easier to access. Four nuts, unclip the drain tube and wires, unclip the switch on the side and lift up.

Pics

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)