When I started using mine, the catch bucket was still putting off a fair amount of steam from the hot water and the cream corn smell isn't great. My solution was to drill a hole in a bucket lid that my drain hose fit snugly in and set it on the bucket. I don't think you'd want to put it on tight, or you might have issues, but it does a pretty good job of knocking down the steam and odors.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boil kettle condenser - no overhead ventilation needed

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I wonder. If we have a condenser to control the escaping steam, wouldn't a standard, home-kitchen-sized, that is to say, affordable, range exhaust hood be able to control the odors? I realize make-up air has to enter the space from somewhere, but the volume would be very much less.

Interesting question, to which I'm going to (speculatively) answer "no."

Here's why I think that: a standard exhaust hood setup will take the rising steam, most of which ends up inside the hood, and exhaust it to the outside. Given the airflow, other volatile boil constituents will also rise up and be exhausted.

Now, take one of our steam condenser setups. Even if you have an exhaust hood over it, from where is it drawing the air? From everywhere. There's nothing carrying steam and other boil constituents up directly into the fan and thus to the outside.

That air will come from everywhere, not just from below. Inside that range hood the fan creates a negative pressure; it will be fed with air from all sides and below the hood, not just from below.

Thus, while it will vent something, it's not going to vent a lot, at least not compared to an exhaust vent into which steam is rising.

*********

That said, you have me thinking about this. The smell in the garage is NG, my wife thinks it's bad, and so do I. I don't really know why it's so apparent, possibly the closed environment. Even opening both garage doors after brewing doesn't fully eliminate the smell.

What's the source of the smell? Those of you who would say "hop odor" haven't smelled this. The odor of hops during the boil is, IMO, an acquired taste, but once acquired, it's a nice part of the brewing process.

I'm talking about a different odor. It's sharper, somehow. I suppose I could attribute this to maybe, possibly, the use of a 5500-watt element but if that were the case, I think I'd have heard about this before.

I have mine draining into a stand pipe under the sink (p-trap between it and the drain). It's occurred to me to see if I'm getting a lot of that odor out of that area; if so, maybe that could be vented effectively, not sure.

The education of Mongoose proceeds.

Gameface

Well-Known Member

I am using the 1.5" steam slayer on a 30gal kettle making 15gal batches and it is keeping up just fine. In fact, the first time I used it I was slow to lower my power as much as needed and I had a boil-over, only there was no boil-over because the steam slayer sucked all the foam in and it went into the bucket.I will have to send him a message. My thought was 2" would just provide more steam flow, especially with the extra elbow, I suppose that 1.5" would work as well and I haven't ruled out using the steam slayer. I had a hard time finding a 4" to 1.5" reducer that I liked but there were many options at 4" to 2". I am really just in the planning phase right now as far as a condenser goes because of the exhaust hood cost. I am also waiting to hear back on some custom work about my ideas on the lid design. A domed lid straight to a 1.5" or 2" TC would be ideal IMO.

vwluv10338

Member

- Joined

- Feb 5, 2018

- Messages

- 10

- Reaction score

- 3

View attachment 604699 First run with my condenser. I had my rig set to just the 1000w element vs the full 1600w and it seemed the boil was still a bit to vigorous. Should I be worried about this with 3 oz of hops?

The worry I'd have is that the hops are sticking to the side instead of in the wort. The hops aren't going anyone any good if they're not in the boiling wort.

My hops also collect on the sides at the top of the boiling wort. I use a squirt bottle with water in it to wash them down into the wort, or use a spoon to spoon wort up on the hops to wash them down again.

I think you can dial that down a bit more yet; I'm using a 5500-watt element in my 10-gallon BK, and I will have that about 28 percent or so; that's partly to reduce the vigor of the boil, partly to ensure the steam slayer can keep up, which it can, even if it's boiling at a high level.

The only downside, such as it is, is that the boiloff is less, so you have to account for that in your recipe and process. When I started this I kept having boiloffs of about 1/2 gallon, less than the normal 1 gallon, and thus a somewhat lower FG than I'd expect. I've been diddling w/ the recipes to deal with this.

ancientmariner52

Well-Known Member

I think you'll have to tell us how it worked. Just offhand, I'd guess that most of the hop goodness is still in the hops. Have you tasted the wort? Perhaps you could scrape the hops down and stir them about to recover some of the value?View attachment 604699 First run with my condenser. I had my rig set to just the 1000w element vs the full 1600w and it seemed the boil was still a bit to vigorous. Should I be worried about this with 3 oz of hops?

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

That boil is too aggressive - hence the hops being deposited on the side.

All brewers should be targeting commercial level boil-off rates of 4-6%. A good simmer should be the goal, not whitewater rapids.

All brewers should be targeting commercial level boil-off rates of 4-6%. A good simmer should be the goal, not whitewater rapids.

vwluv10338

Member

- Joined

- Feb 5, 2018

- Messages

- 10

- Reaction score

- 3

I figured it might be an issue. I will have to figure something out because I can't really dial the boil down on the Mash and Boil like you guys can with your PID controllers. Maybe I can set the temp a bit lower, more like on the verge of boiling. I did not taste the wort but it smells like hops in the blow off tube.

Do you guys think the condenser stack this guy is holding would be overkill for a 20 gal BK?

All joking aside, it is amazing to see that we can build/buy one for the homebrew scale that doesn't require a custom application specific piece to be made.

All joking aside, it is amazing to see that we can build/buy one for the homebrew scale that doesn't require a custom application specific piece to be made.

I had my rig set to just the 1000w element vs the full 1600w and it seemed the boil was still a bit to vigorous.

Can the Mash & Boil run just the 600 watt element?

Gameface

Well-Known Member

So I think the steam condenser should be the Homebrewtalk.com innovation of the year 2018. Who's with me? How do we make this happen?

This has been the biggest game changer in home brewing in 2018 hands down.

Who do I need to talk to to make this happen?

This has been the biggest game changer in home brewing in 2018 hands down.

Who do I need to talk to to make this happen?

I like that idea, and I'm making some inquiries.So I think the steam condenser should be the Homebrewtalk.com innovation of the year 2018. Who's with me? How do we make this happen?

This has been the biggest game changer in home brewing in 2018 hands down.

Who do I need to talk to to make this happen?

Brew on

vwluv10338

Member

- Joined

- Feb 5, 2018

- Messages

- 10

- Reaction score

- 3

Can the Mash & Boil run just the 600 watt element?

No, I wish. The robobrew does 500/1000/1500 because you can turn on the elements independently but the M&B does 1600/1000

So I think the steam condenser should be the Homebrewtalk.com innovation of the year 2018. Who's with me? How do we make this happen?

This has been the biggest game changer in home brewing in 2018 hands down.

Who do I need to talk to to make this happen?

Agreed, 100%

emr25

Well-Known Member

- Joined

- Oct 19, 2015

- Messages

- 123

- Reaction score

- 89

Used the Steam Slayer for the first time last night in conjunction with the Grounded eBIAB system, worked perfectly! The 6gph nozzle produced 7 gallons of waste water over a 60 minute boil with my system. Definitely had a cooked corn smell and boil-off was about 6-7%.

Used mine for the first time for a brew yesterday also. I bought parts back in the summer but just now got around to drilling my kettle. I’d be interested in what folks are doing for odor control.....it was much worse than I expected. I have a pico zymatic and it was much much worse than the odor it produces. I was thing about a bucket with a carbon filter, or running it to a Sump pit or just using a window fan. I was using a diy hood (30qt bowl with hydroponic fan) which worked well but was such an eyesore I wanted to get rid of it.

missiletech

Active Member

- Joined

- Nov 8, 2015

- Messages

- 41

- Reaction score

- 1

I have a 1BBL stout system with a Brewmation control panel and two 5500w elements per kettle.

Any suggestions for adapting this concept to my rig? I generally run around 25 gallon brews, occasionally 30+.

Steve

Any suggestions for adapting this concept to my rig? I generally run around 25 gallon brews, occasionally 30+.

Steve

ancientmariner52

Well-Known Member

I still haven't had the opportunity to try out my steam slayer, but I'm well known as the fool that rushes in, so here goes: with normal open boiling, the compounds that produce the smell are dispersed and diluted by the large volume of steam, producing the wonderful odors that we either love or hate.Used mine for the first time for a brew yesterday also. I bought parts back in the summer but just now got around to drilling my kettle. I’d be interested in what folks are doing for odor control.....it was much worse than I expected. I have a pico zymatic and it was much much worse than the odor it produces. I was thing about a bucket with a carbon filter, or running it to a Sump pit or just using a window fan. I was using a diy hood (30qt bowl with hydroponic fan) which worked well but was such an eyesore I wanted to get rid of it.

When we condense most of the steam, we also catch some of the odor compounds, hence the 'fragrant' condensate. The more volatile compounds end up in the air, and without the steam and other components, don't smell nice at all.

Well, that's my theory, and I'll stick with it until somebody smarter tells me what's wrong with it. That shouldn't take long.

I'm thinking it wouldn't take too much of an exhaust system to overcome this little hiccup. Maybe use your unaesthetic bowl exhaust on top of the catch bucket?

ancientmariner52

Well-Known Member

Keep us updated, please. I'm still working on my brewing space, this thread has been tremendously helpful.Yeah, I might give the hood over the bucket idea a go to see how that works. I plan to run it to a drain long term.

I'm brewing tomorrow, and I dump the water to a drain; I'll do some more investigating and see if that's where the smell is originating.

fragged

Well-Known Member

Well, that's my theory, and I'll stick with it until somebody smarter tells me what's wrong with it. That shouldn't take long.

What's wrong with it would depend on the smell. I don't run into this as I run it down the drain.

I would be doubtful it's the hops side of things unless someone hates the hop smell. The lowest boiling point I'm aware of for the compounds in hops is 223F(other than any residual H2O), with most being well above 300F.

I'd be curious to know what it smells like, as compared to say household spices or other household chemicals (citronella candles as an example). That would help give an idea what the compound is, and may yield an additive you guys could use to react with it in the bucket. Changing the compound to something more to your liking or nuetral, ideally. Or just run to a drain [emoji482]

Another question I'd have is whether they are using treated water(ro/distilled) for the brew, but tap/well for the condenser. Maybe something funky in the condensing water?

missiletech

Active Member

- Joined

- Nov 8, 2015

- Messages

- 41

- Reaction score

- 1

I had a hard time finding a 4" to 1.5" reducer that I liked but there were many options at 4" to 2"

FYI ...this may work for you? https://www.ontariobeerkegs.com/SS_...C_x_1_5_TC_p/ss-4tc-x-1.5-tc-cone-reducer.htm

I brewed today using the steam condenser, and had the same kind of smell. It did seem to be coming, at least in part, from under the sink where I drain it.

@fragged asked about what it smells like. It's hard to describe, but perhaps the closest I can come is it's a sort of burned hop smell.

That leads me to question if the electric element might have something to do with this. Mine always has a layer of something on it at the end (it disappears with a soak in hot PBW).

I opened the garage doors about 40 minutes into the boil, to clear out as much smell as I could. It worked pretty well actually, and while the smell hung around, it didn't seem to recreate itself.

I brewed a variant on a Mexican Lager, so if there are any off flavors in it from this effect, I should be able to detect them.

@fragged asked about what it smells like. It's hard to describe, but perhaps the closest I can come is it's a sort of burned hop smell.

That leads me to question if the electric element might have something to do with this. Mine always has a layer of something on it at the end (it disappears with a soak in hot PBW).

I opened the garage doors about 40 minutes into the boil, to clear out as much smell as I could. It worked pretty well actually, and while the smell hung around, it didn't seem to recreate itself.

I brewed a variant on a Mexican Lager, so if there are any off flavors in it from this effect, I should be able to detect them.

I had my very first brew on a 20 gal Spike system on Wednesday, with virtually zero odors coming from the Steam Slayer or Condensate. There was no steam as well, so I know it worked. Now, I'm a little worried that I didn't stink up my garage.

That said, could it have been that with a first brew with nothing on the elements could have held the odors down? That would confirm Mongoose's theory about the electric element above.

That said, could it have been that with a first brew with nothing on the elements could have held the odors down? That would confirm Mongoose's theory about the electric element above.

I don't know. I just love this thing, as it enabled me to purchase my Spike system and brew in larger batches. I vote for invention of the year.That leads me to question if the electric element might have something to do with this. Mine always has a layer of something on it at the end (it disappears with a soak in hot PBW).

I had my very first brew on a 20 gal Spike system on Wednesday, with virtually zero odors coming from the Steam Slayer or Condensate. There was no steam as well, so I know it worked. Now, I'm a little worried that I didn't stink up my garage.

That said, could it have been that with a first brew with nothing on the elements could have held the odors down? That would confirm Mongoose's theory about the electric element above.

I don't know. I just love this thing, as it enabled me to purchase my Spike system and brew in larger batches. I vote for invention of the year.

Where are you running your drain? It sounds like those running there drain line to a plumbed drain opening or outside their indoor area are not having odor issues? I’m interested if running to an open drain vs bucket eliminates the issue. I’m considering drilling a port on my stainless sink to allow my drain line to go to the sink drain or running a pvc line to my sump pit (brewing in my basement). Thanks

I'd be hooking it up to this. I'm curious if increasing the chamber (the tee) to a larger size will increase the affect or if the whole assembly would need it... or if it's just unnecessary.

Any thoughts would be appreciated!

View attachment 605960 View attachment 605960

I would use a 2” or more.

missiletech

Active Member

- Joined

- Nov 8, 2015

- Messages

- 41

- Reaction score

- 1

I would use a 2” or more.

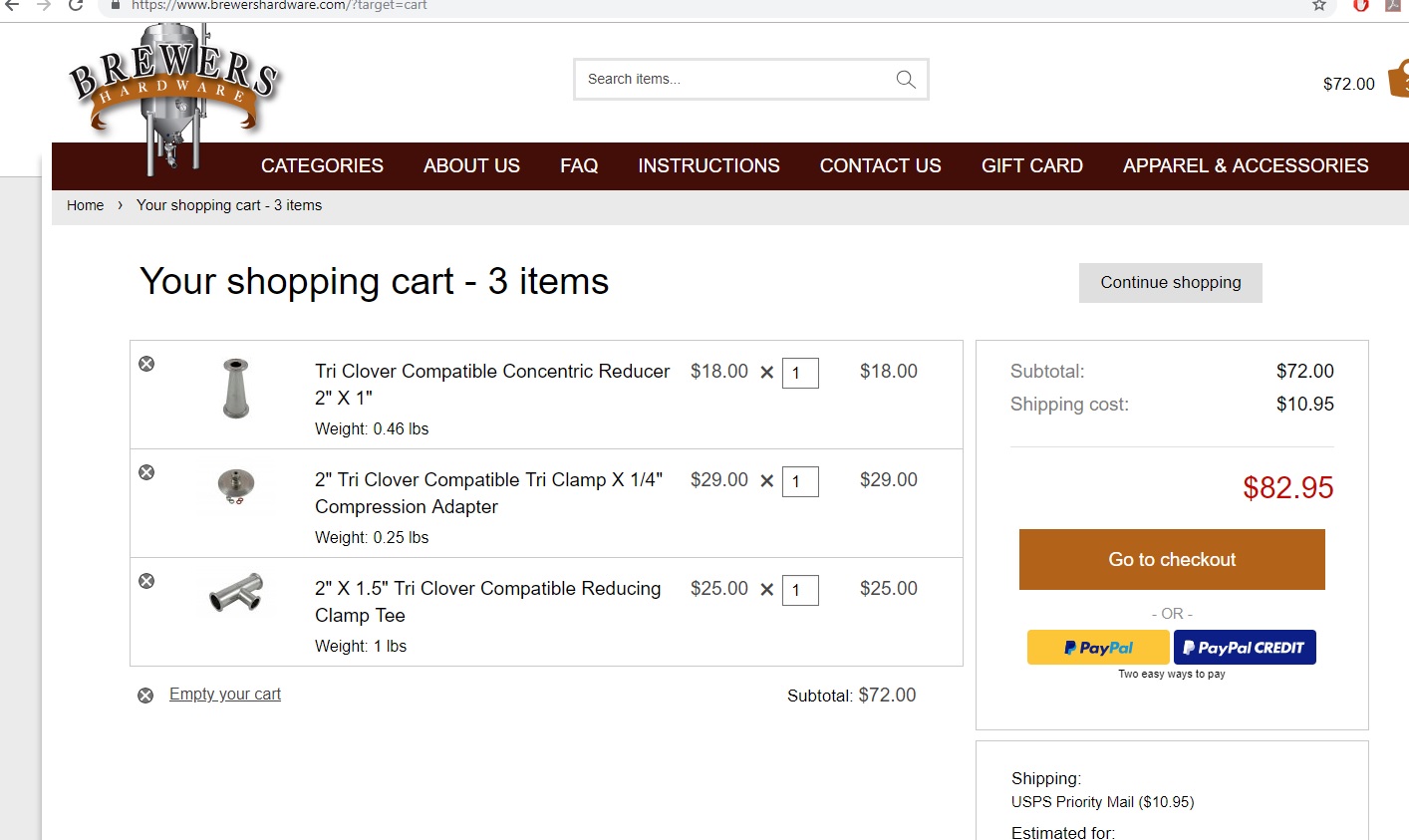

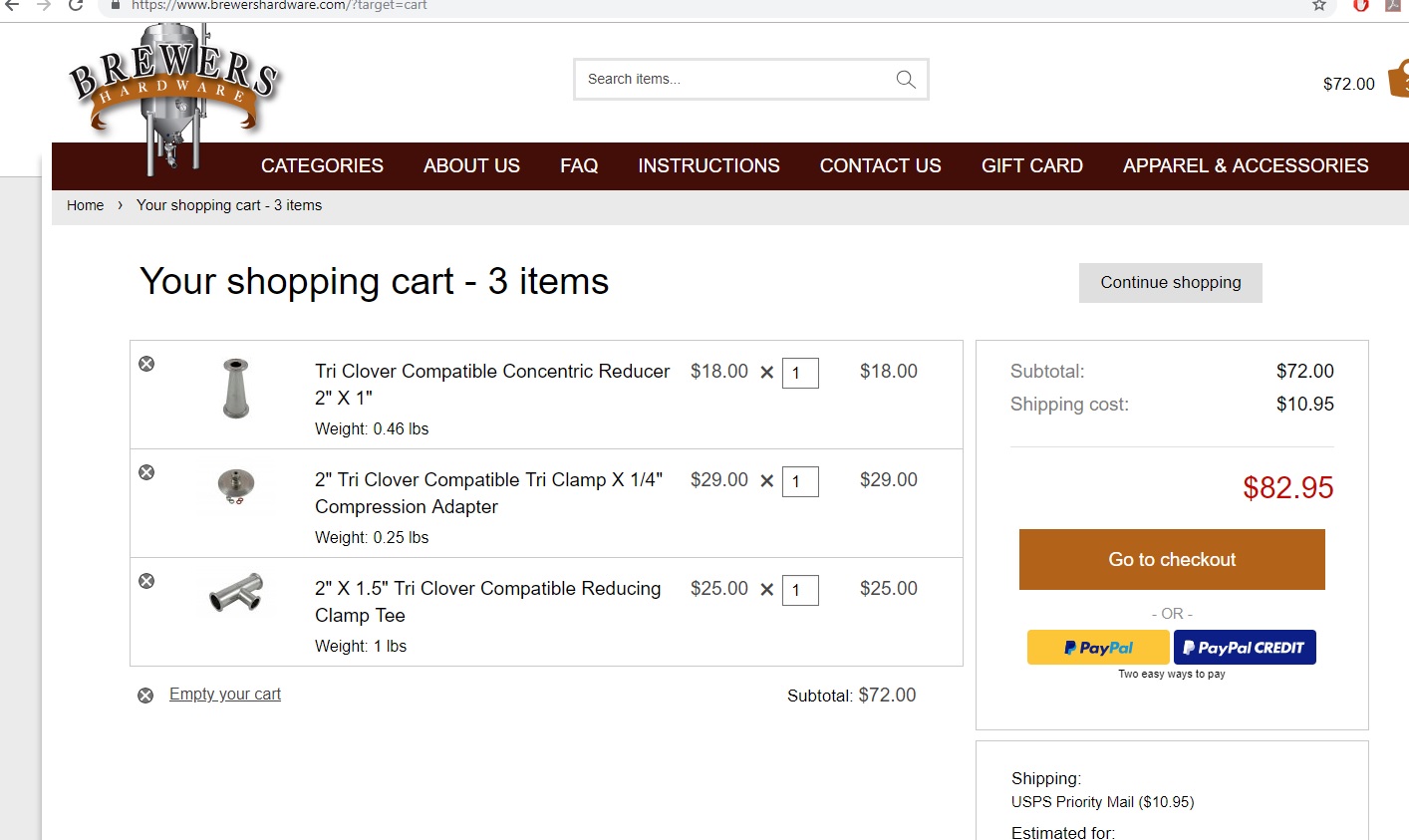

For the connection to the tank/kettle or just the chamber? Reason is that I see that is the brew boss one seems to have smaller intake (1/2" or 5/8") going into 1.5" TC chamber. I assume I 'could' have similar performance with an offset inlet to chamber. Stilldragon sells a 2" TC bulkhead for:

https://www.glaciertanks.com/tri-clamp-fittings-long-tees-b7mp-g200.html

Or I could run 1.5" to:

https://www.brewershardware.com/2-X...ng-Clamp-Tee-TC20TEEX101.html?category_id=328

<20 minutes later>

I think I just went full shiny object syndrome.... I'll revisit this later.

EDIT: We're trying to build a new house and if it works out this setup is going in the garage and I want to avoid extensive ventilation. No-one minds the brewing odors and worst case scenario I open the man door if I had something smell off.

Last edited:

missiletech

Active Member

- Joined

- Nov 8, 2015

- Messages

- 41

- Reaction score

- 1

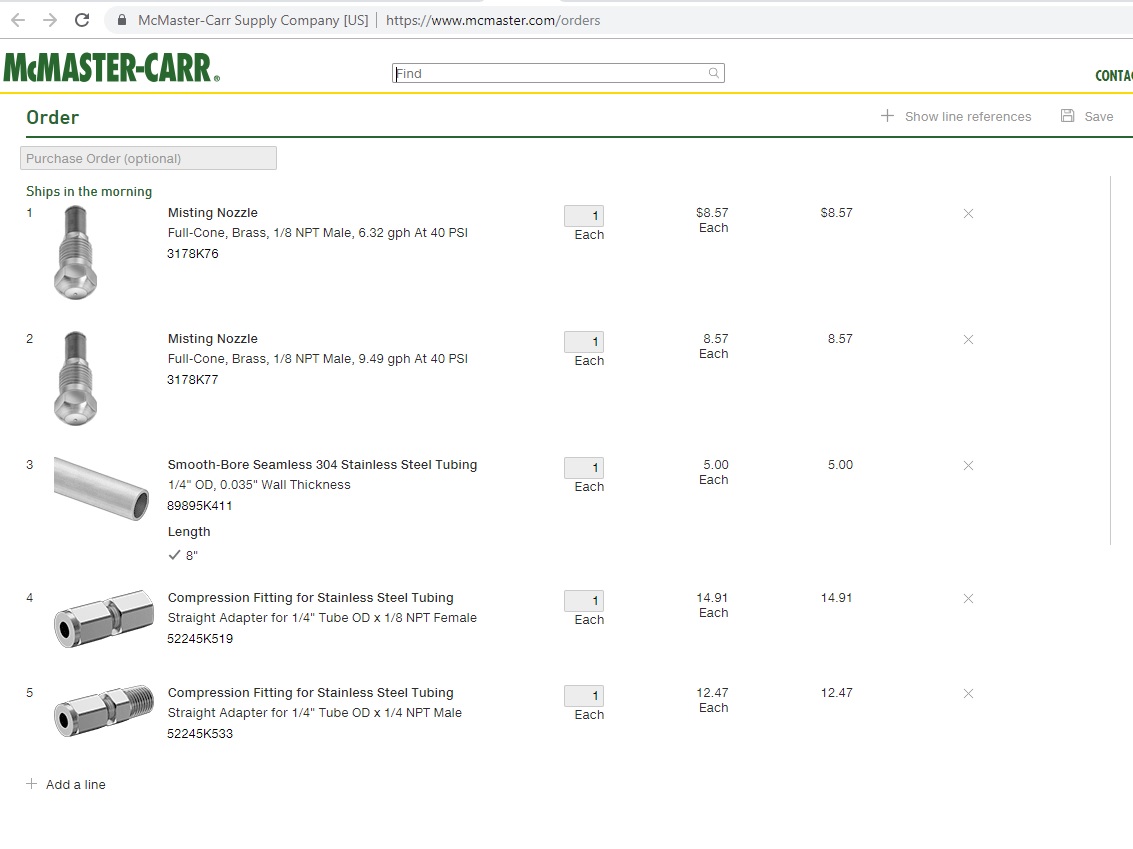

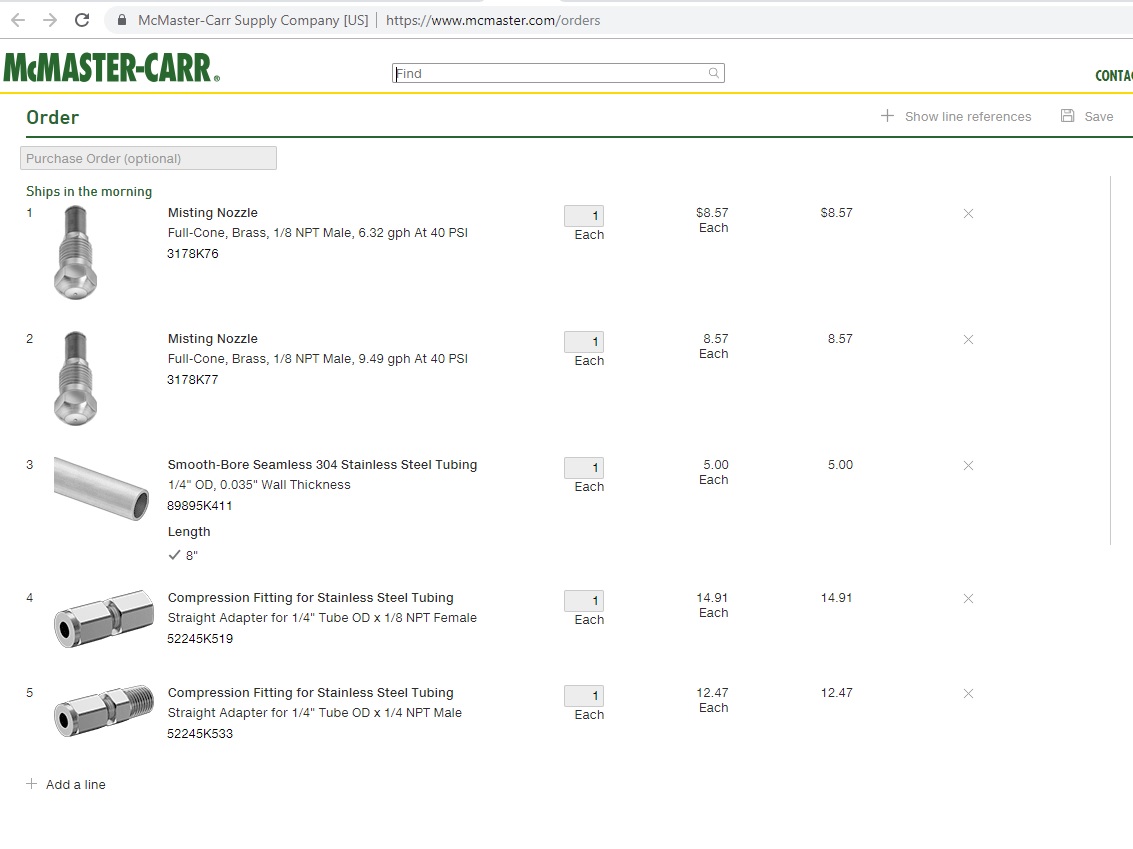

I could try something like this then once I get the garage situated I can run a PEX line from the sink to connect to the tubing NPT with a small valve. The reducer would just be in lieu of a spool to add some length for volume beneath the steam inlet since it's not a cool tee like the steam slayer.

Supposed to be pouring a foundation in the next few weeks so I might be able to buy toys again... maybe.

Supposed to be pouring a foundation in the next few weeks so I might be able to buy toys again... maybe.

Similar threads

- Replies

- 2

- Views

- 906

- Replies

- 1

- Views

- 445

- Replies

- 11

- Views

- 890

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)