HawleyFarms

Well-Known Member

Everybody still alive? Starting my third addition of these in the coming weeks. Been so busy with work that I've only been doing one of these a year instead of my original intentions to do one every 4 months.

Never did manage to get one made last year and 2016's blend is still sitting in the carboy. Life really got in the way in 2017 and I just never had time for brewing of any sort. I think my first batch is by far the best one.This brewer has been quiet a bit to long, time to wake up the yeast and find my hydrometer again. Hey everybody, after nearly 2 years handling life I'd like to say it's time to do that 5th generation haha. Cleaning out my shop making way for more storage and future home projects, I found myself wondering what these bottles and jugs of dark amber liquid were. Kind of crazy how you can lose track of time and especially when i realize when we started this so many years ago. Hope there may be some blends still out there going strong, i'll hopefully update on the state of mine since my yeast/lees are certainly gone but I'm curious how the 4th gen tastes from the bottle now.

Cheers all!

Apologies beforehand if this is bumping a dead thread, this was a fun group brew and idea that I stuck with for quite some time. Having a side eyed obsession with nailing down a solid recipe the solera style blending adds some forgiveness in the long run of a generation gets away.This is quite an old thread but I like the idea...

Anyone interested in starting this up as a new thread/project?

I'm thinking 5 or 6 generations. That takes you out to about 3 years and if you are doing an oak barrel, about your useful extraction out of it

I like the idea of this. I've blended a few different meads in the past, but it was just by the glass, not to keep aging.Apologies beforehand if this is bumping a dead thread, this was a fun group brew and idea that I stuck with for quite some time. Having a side eyed obsession with nailing down a solid recipe the solera style blending adds some forgiveness in the long run of a generation gets away.

I stuck with this through 2020 and have the last of 4 carboys hiding in the back of my brew shelf collecting a surprising amount of dust... No idea why I have let this age so long because it was a lot of fun. I can't remember what generation this ended up with but I think a group brew would be fun again.

Shout out to MightyMosin for the suggestion and I think if we wanted to try it again it would bring a fun new experience for a lot of brewers. If anyone else would like to chime in about renewing or continuing solera style bochet as a group brew let's hear it. I started this when I was fairly new to brewing so anyone just beginning or learning, group brews used to be my favorite place to experience and discover new ideas so feel free to join in or ask about the process.

Cheers.

Agreed. If there was a date that people could plan it around, that might appeal to a larger crowd/group.Originally I believe 3 people were on board to kick things off and others slowly joined up, myself included, no reason to wait for a number of people. If anyone thinks a predetermined date to kick things off again would be best, that might give some time to clarify any processes and aquire new brewers, i like the idea of a group kickoff. Kind of like the old group/club/national brew days when everyone started the same recipe on a weekend.

It wouldn't help people see it, updating and commenting will keep it updated in the forum thereby allowing more views.Agreed. If there was a date that people could plan it around, that might appeal to a larger crowd/group.

Not sure if a new thread should be started though. Would that help people see it?

I could be down for mid January. Some time for the holidays to settle down.It wouldn't help people see it, updating and commenting will keep it updated in the forum thereby allowing more views.

That said, if anyone around here would like to join in on a group brew, the concept is fairly simple and fun. Feel free to join in, ask about bochet or solera systems and have fun with us.

I'm thinking about early January I would be able to get in a brew day, currently doing some interior remodeling that has me occupied until Christmas, any thoughts on January or later? Of course future participants can start up whenever they join in.

Glad to hear it, I was hoping you would reply as I recall you were the one to bump the thread.I'm in, which is why I originally bumped the thread.

I'll get another barrel for this. I figure I can do a 7 gallon initial batch and then rack into a barrel. After that, ~4 gallon batches will be good for me to keep the barrel topped up every ~ 6 months.

I agree that mid January might be a good point to start on it.

So, this will be your recipe to follow then, correct? Or are we each coming up with our own?I need to start finalizing a recipe to kick things off when I do.

I like the idea of the Bochet, as the original post suggests.(as seen on gotmead)

Hello Everyone! I haven't seen a group brew pop up in a while, so I figured it was time to come up with one. One of the more intriguing styles I've seen (in my opinion) grow in popularity over the past few years is the Bochet (mead with caramelized honey).

------------------------------------------------------------------------------------

So taking that, and adding a bit of flare to it with the Solera style of aging. Solera aging is as follows: This is normally done in barrels but we can do oaked carboys for the sake of convenience (if you have a bunch of barrels, more power to you, but won't be required to join on in).

To start, you would brew a batch of bochet, and at 6 months, brew another one. At 12 months you would brew a third and so on at 6 month intervals to however many carboys you want.

When you are ready to bottle: You bottle only from your FIRST Carboy. You also don't completely empty the carboy. Instead you leave a portion behind (1/3 - 1/2) and refill the original carboy from the next generation (your second carboy). And your second carboy is refilled form the third, and so on and so on until you reach your last carboy. Your last carboy is then filled with new must and fermented.

If that didn't make any sense, there is a Wikipedia article here that may clear things up. Solera - Wikipedia

Why I chose Bochet style for this: The process in making bochet can be a bit unpredictable in that the amount of caramelization you get can change from batch to batch if you are even a minute or two off, or your temps weren't the same as your last batch. This change loans itself well in emulating different characters of different years grape harvests.

------------------------------------------------------------------------------------

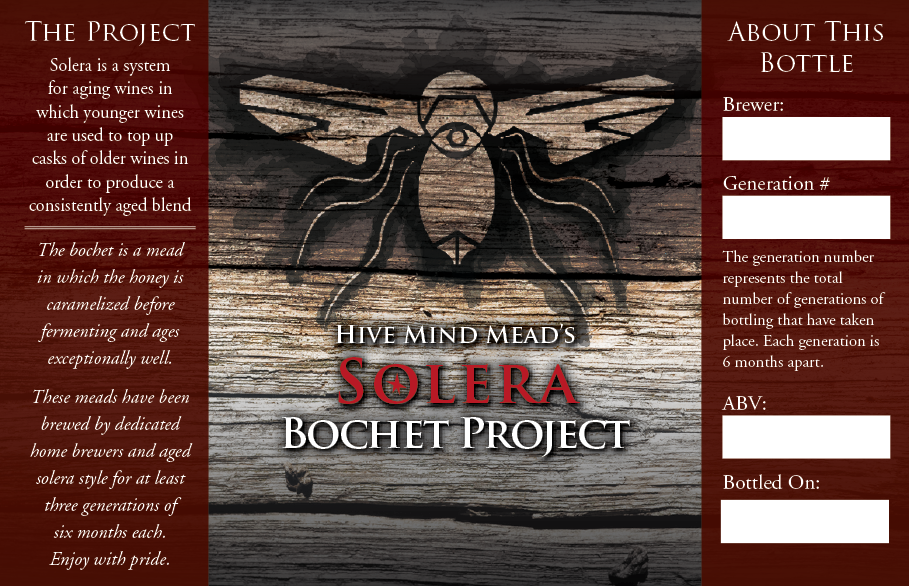

What we'll do is gather some participants, then we'll let everyone start on their own time and we can all watch each others progress and notes. Anyone interested in trading batches down the road I've put together a label we can use (or you can make your own!)

The rules are as follows: (these are completely open to suggestions and changes based on participant feedback).

1. 75% of your honey must be Caramelized for each generation.

2. You must have at least 3 generations (No maximum)

3. You may change your recipe for each generation (new yeast /ingredients); but remember that these will be blended down so crazy outliers may hurt future generations.

4. Generations rotate every 6 months (Stay as close to this as you can, not a hard rule)

5. HAVE FUN, and learn about blending and Solera Aging along the way!

6. Late Joiners will be allowed to join any time!

So, with all that, Who's IN!? Remember that if you have a suggestion for the rules to give your input before we begin.

Generation Schedule would just be ~6 months from when you started (Example if you started in mid-July),

G1. July 15th

G2. January 15th

G3. July 15th

...and so on and so on...

Oh no, everyone can follow their own recipe of choice, I meant I need to finalize what I plan to brew so I'm not coming up with 6 different ideas in front of the stove.So, this will be your recipe to follow then, correct? Or are we each coming up with our own?

I agree with that. For me, a bochet should be @ least 51% caramelized honey for the fermentable sugars. I'm looking forward to this.Oh no, everyone can follow their own recipe of choice, I meant I need to finalize what I plan to brew so I'm not coming up with 6 different ideas in front of the stove.

As to Mighty's point on the amount of caramelized honey, what about treating bochet similarly to the standard mead definition (majority of fermentable sugars.) E.g. for a melomel to be such and not a wine the majority of fermentable sugars must come from honey. I've always looked at bochet the same, majority of the honey 51-100% should be caramelized. Just my opinion, feel free to share your own thoughts.