HRNCBrewer

Member

I have a 23 jet natural gas burner for my brew kettle like in the attached image.

I also have a similar, but smaller (fewer jets) burner for the HLT.

The smaller burner works fine, but the 23 jet burner puts out lots of sooty black smoke.

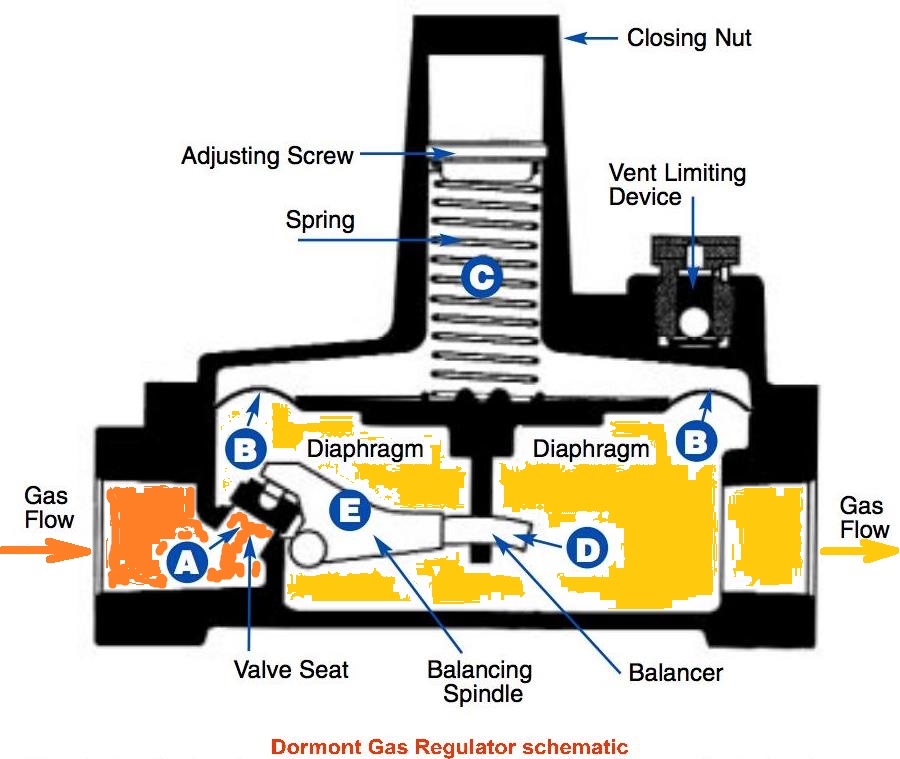

I added a natural gas pressure regulator, but that made no difference.

I believe the problem is insufficient air to the jets so I am getting incomplete combustion (lots of CO!).

Can someone tell me how I can fix this so that I get more oxygen to the burner?

Thanks for any advice.

Tony B.

I also have a similar, but smaller (fewer jets) burner for the HLT.

The smaller burner works fine, but the 23 jet burner puts out lots of sooty black smoke.

I added a natural gas pressure regulator, but that made no difference.

I believe the problem is insufficient air to the jets so I am getting incomplete combustion (lots of CO!).

Can someone tell me how I can fix this so that I get more oxygen to the burner?

Thanks for any advice.

Tony B.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)