Jlaitila140

Member

- Joined

- Dec 3, 2015

- Messages

- 22

- Reaction score

- 2

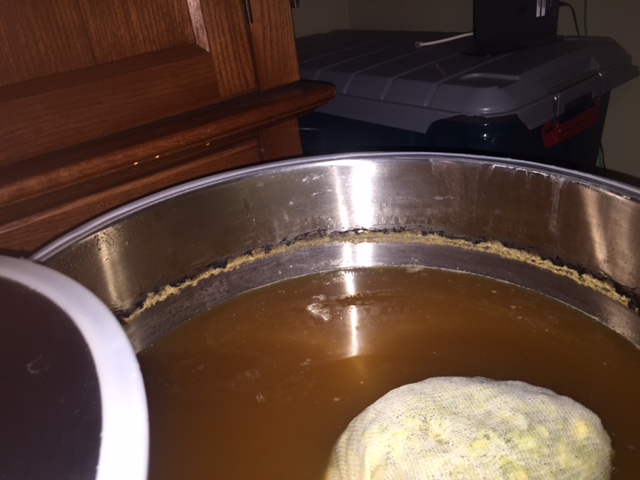

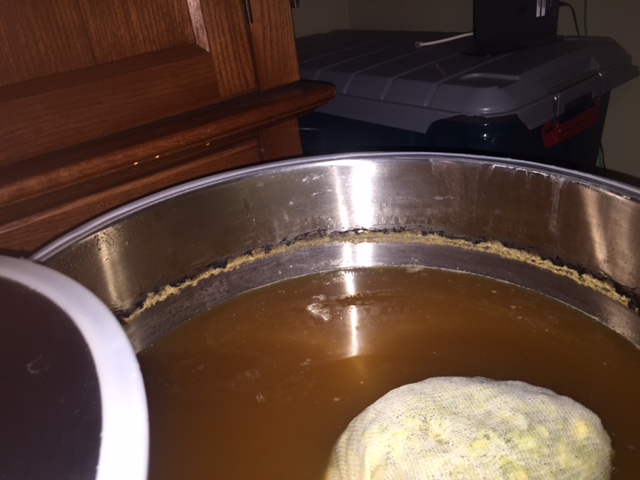

I made my very first beer EVER (simcoe/centennial IPA) on the 25th of November, dumped yeast and trub on the 2nd of Dec, dry hopped today and noticed blackness in the yeast ring when i popped the lid.... I have read a few threads on it but can't find any definitive reasoning for this event, some say the beer is bad some say its fine.. I plan on Kegging the beer this Wednesday and taking a chance...does anyone have any idea what the black in the krausen ring is?

I cleaned and scrubbed it with hot water and dawn day prior to brew day... then with PBW and hour prior, then with star san during the boil.

The only thing that went outside of the bounds of normal was the mash temp got too high (raised to 170 due to a temp probe failure), but got it back to 152 within 15 mins,other than that everything went to plan.

any advise will help me sleep tonight

Thanks

JJ

I cleaned and scrubbed it with hot water and dawn day prior to brew day... then with PBW and hour prior, then with star san during the boil.

The only thing that went outside of the bounds of normal was the mash temp got too high (raised to 170 due to a temp probe failure), but got it back to 152 within 15 mins,other than that everything went to plan.

any advise will help me sleep tonight

Thanks

JJ