My 2 cents: Go to slightly larger batches, like 2.5-3 gallon. Why? I've found that too small of a mash doesn't have much thermal mass and its more difficult to maintain a steady temperature. I get high efficiency by using the batch size in the mash (example 2.5 gallons) and then putting the evaporation and grain absorption water in a side pot, (about 2 gallons) heating that and do a dunk sparge/stir in the side pot. For some reason I get higher efficiency doing this instead of a full volume mash. But your results may vary.

Making sure the beers aren't watery is going to be somewhat dependent on your recipe and ingredients, but having a nice steady mash temperature can also play a role.

I also dump into the fermenter by hand, which is way easier with small batches, and I account for an extra 1/2 gallon or so of trub/hops when I'm figuring my total water volume. Sometimes if I'm being really cheap, I'll dump the 1/2 gallon of trub into a sanitized glass jug, let that settle and then add a pint or two of extra wort to the fermenter.

For small batches, there's a good chance you can fit your vessel in your oven set to about 150°-160°F. This will minimize any heat loss due to low thermal mass of a small batch.

Mash efficiency is equal to conversion efficiency times lauter efficiency, and brewhouse efficiency is equal to mash efficiency times fermenter volume divided by post-boil volume. So maximizing mash efficiency means maximizing conversion efficiency (100% is achievable), maximizing lauter efficiency (100% is not possible.) Maximizing brewhouse efficiency means maximizing mash efficiency, and minimizing volume loss in the transfer from the BK to the fermenter.

100% conversion efficiency means you have converted all of the available starch into sugars and dextrins. You can directly measure conversion efficiency using the

method here. If you aren't getting 95% or better conversion, you should look first at going to a finer crush, then at mashing longer. Crush primarily affects the rate of conversion, because gelatinization of starch grits must occur before the starch can be acted on by amylase. So, gelatinization is the rate controlling step in conversion. Gelatinization starts at the surface of the grain grits, and proceeds towards the center, thus smaller grits completely gelatinize faster than larger grits, and therefore complete conversion faster.

Mash temp also affects gelatinization rates, with gelatinization occurring faster at higher temps. So, all else being equal a lower temp mash will convert slower than a higher temp mash, and will require a longer mash time to complete conversion. If the mash temp is too high, then you risk denaturing the enzymes before they can complete their work.

pH has a relatively small effect on gelatinization rate, so plays less of a role in conversion efficiency than most people think.

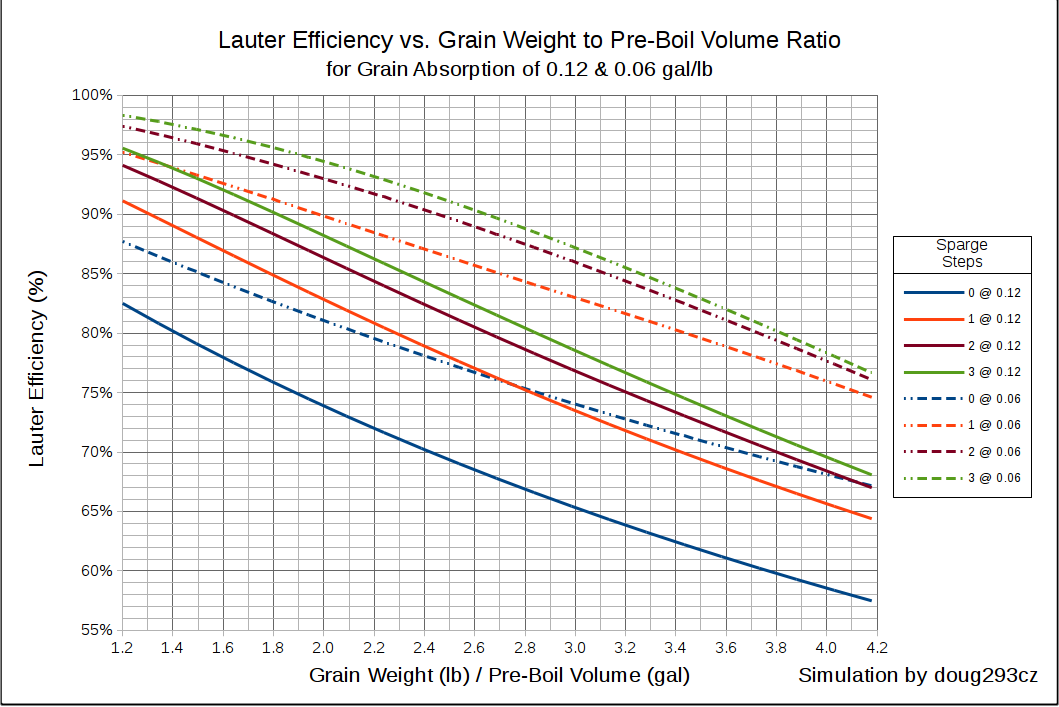

Lauter efficiency depends on how much of the sugar you created in the mash gets left behind with the spent grain. You increase lauter efficiency by reducing the grain absorption rate (by extended bag draining and/or squeezing the bag), and/or sparging the grain after initial draining/run-off (sparging rinses sugars from the spent grain grits.) Lauter efficiency can be predicted if grain weight, water volumes, grain absorption rate, and sparge details are known. The chart below shows the maximum achievable lauter efficiency for different grain weight to pre-boil volume ratios, grain absorption rates, and number of batch/dunk sparge steps.

0.12 gal/lb is the typical absorption rate for a traditional MLT, and what you might see with a short bag drain using BIAB. 0.06 gal/lb is what can be achieved with a moderately aggressive bag squeeze. Long draining alone can get you in the 0.11 to 0.08 gal/lb absorption rate. You should measure the absorption rate for your particular process in order to be able to predict mash efficiency.

Lauter efficiency is increased by decreasing the grain absorption ratio, and/or adding sparge steps.

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)