Bigarcherynut

Well-Known Member

I've been doing BIAB brewing for several years. I took time off a couple of years ago to work on my system, create software from developers here and get an understanding on water issues I had with my well water. Since then things have gone well. I started kegging this spring and what a change. I'm brewing more than ever.

I love brewing Stouts and now Bourbon Stouts. This year I wanted a light summer beer and came up with a Cream Ale. Brewing for many is just to be able to brew drinkable beer. The same for me but with my Cream Ale, has now become repeating a recipe brew after brew. That's where this is heading.

I have made 5 batches of the Cream Ale. 2, 5 gallon batches and 3, 10 gallon batches. I use RO water along with my well water in a 90 RO to 10 percent well water ratio. Water profile is the same and gives me a great flavor. The problem is my efficiencies dropped when I brewed the 10 gallon batches.

Efficiencies for batches from BeerSmith and Grain/Water amounts:

5 Gallon Batch #1 - 83% BH Eff. - 83% Mash Eff Grain Bill 9.75/Water 7.29 Gal

5 Gallon Batch #2 - 85% BH Eff. - 85% Mash Eff Grain Bill 9.75/Water 7.54 Gal

10 Gallon Batch #3 - 80% BH Eff. - 84% Mash Eff Grain Bill 19.5/Water 12.98 Gal

10 Gallon Batch #4 - 70% BH Eff. - 73% Mash Eff Grain Bill 21.5/Water 13.88 Gal

10 Gallon Batch #5 - 67% BH Eff. - 70% Mash Eff Grain Bill 21.5/Water 13.88 Gal

I know most will say don't worry about not hitting numbers but I'm working hard to repeat recipes. I'm trying to set my water amount to get 5 gallons into the kegs so that's why a slight increase in water from batch #1 and #2. Batch #3 was only 14 #'s of base malt compared to 16 #'s for batches #4 & #5. So a slight increase in water. Even after adding 2 pounds more base malt both batch #4 & #5 were below my estimated OG's shown on BS.

When the efficiencies started to drop, I posted and many said and I agreed mill finer but my LHBS wont change the mill setting so I got an early Christmas present a grain mill. Batch #5, which I brewed Thursday was with my own mill. It was the worst.

Notes:

1. pH levels tested at 10 minutes into mash and are on around 5.2 to 5.4

2. 60 Minute mash and boil except on batch #5. Boiled extra 20 minutes to hit my OG

3. Did double mill of grains at LHBS

4. I squeeze with two boards and clamps and get a lot of wort out.

5. I circulate during mashing

6. Mash Temps are at 153 constantly with well insulated E-Kettle

7. I'm working hard at making enough beer to fill a 5 gallon keg so when I say a 5 gallon batch I actually try to finish with 5 gallons into keg so I base my grain and water on this taking all losses into consideration.

8. I stir my mash quit often but noticed on my last batch #5, between stirrings the mash would clump up on the bottom of the bag. Maybe because I finally have a finer grain bed.

9. My kettle design is an oval. 26" L x 13" W x 16" D. 20 gallons so my mash is spread out.

Ideas:

1. On the 10 gallon batches mash 90 minutes?

2. Do a mash out?

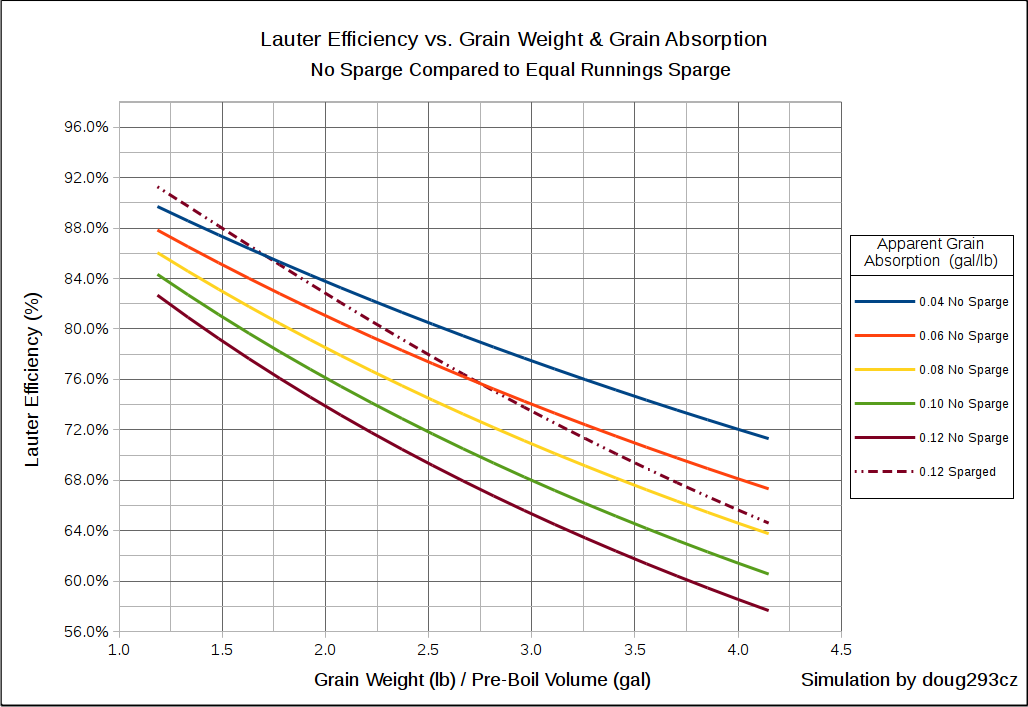

3. Doing BIAB I don't want to sparge but could easily by lifting the bag, drain the wort because I have a bottom drain, add sparge water and heat it, lower bag on top of my false bottom then pump sparge water over the top of my grains.

4. Just add more base malt but I feel like resolving the problem rather than put a band aid on it.

Sorry for the lengthy post but want to cover all the bases.

Thanks for your help and ideas.

Bill

I love brewing Stouts and now Bourbon Stouts. This year I wanted a light summer beer and came up with a Cream Ale. Brewing for many is just to be able to brew drinkable beer. The same for me but with my Cream Ale, has now become repeating a recipe brew after brew. That's where this is heading.

I have made 5 batches of the Cream Ale. 2, 5 gallon batches and 3, 10 gallon batches. I use RO water along with my well water in a 90 RO to 10 percent well water ratio. Water profile is the same and gives me a great flavor. The problem is my efficiencies dropped when I brewed the 10 gallon batches.

Efficiencies for batches from BeerSmith and Grain/Water amounts:

5 Gallon Batch #1 - 83% BH Eff. - 83% Mash Eff Grain Bill 9.75/Water 7.29 Gal

5 Gallon Batch #2 - 85% BH Eff. - 85% Mash Eff Grain Bill 9.75/Water 7.54 Gal

10 Gallon Batch #3 - 80% BH Eff. - 84% Mash Eff Grain Bill 19.5/Water 12.98 Gal

10 Gallon Batch #4 - 70% BH Eff. - 73% Mash Eff Grain Bill 21.5/Water 13.88 Gal

10 Gallon Batch #5 - 67% BH Eff. - 70% Mash Eff Grain Bill 21.5/Water 13.88 Gal

I know most will say don't worry about not hitting numbers but I'm working hard to repeat recipes. I'm trying to set my water amount to get 5 gallons into the kegs so that's why a slight increase in water from batch #1 and #2. Batch #3 was only 14 #'s of base malt compared to 16 #'s for batches #4 & #5. So a slight increase in water. Even after adding 2 pounds more base malt both batch #4 & #5 were below my estimated OG's shown on BS.

When the efficiencies started to drop, I posted and many said and I agreed mill finer but my LHBS wont change the mill setting so I got an early Christmas present a grain mill. Batch #5, which I brewed Thursday was with my own mill. It was the worst.

Notes:

1. pH levels tested at 10 minutes into mash and are on around 5.2 to 5.4

2. 60 Minute mash and boil except on batch #5. Boiled extra 20 minutes to hit my OG

3. Did double mill of grains at LHBS

4. I squeeze with two boards and clamps and get a lot of wort out.

5. I circulate during mashing

6. Mash Temps are at 153 constantly with well insulated E-Kettle

7. I'm working hard at making enough beer to fill a 5 gallon keg so when I say a 5 gallon batch I actually try to finish with 5 gallons into keg so I base my grain and water on this taking all losses into consideration.

8. I stir my mash quit often but noticed on my last batch #5, between stirrings the mash would clump up on the bottom of the bag. Maybe because I finally have a finer grain bed.

9. My kettle design is an oval. 26" L x 13" W x 16" D. 20 gallons so my mash is spread out.

Ideas:

1. On the 10 gallon batches mash 90 minutes?

2. Do a mash out?

3. Doing BIAB I don't want to sparge but could easily by lifting the bag, drain the wort because I have a bottom drain, add sparge water and heat it, lower bag on top of my false bottom then pump sparge water over the top of my grains.

4. Just add more base malt but I feel like resolving the problem rather than put a band aid on it.

Sorry for the lengthy post but want to cover all the bases.

Thanks for your help and ideas.

Bill