Bigarcherynut

Well-Known Member

Been brewing BIAB for about 6 years. Took a year off to get an understanding of water quality and to design my own software for the unique E-Kettle I built. Thanks to two software designers on HomeBrewTalk.com for their help. I now really have a system and program that has been working great.

I love stouts, porters and lately brewing bourbon stout. This spring I wanted to brew a beer that was a good summer beer. Something light but yet have some body better than the Bud, Coors, Miller and Bush Lights. Well after tying many suggested flavors settled in on a Cream Ale.

Well my first recipe was spot on for what I wanted and I have brewed 4 batches. The first two were 5 gallon batches. They both came in at 83% BH efficiency which is where most of my beers come in at. I decided to increase my batch to a 10 gallon batch and although it was the same taste, my efficiency dropped to 75 %. Not bad but puzzling. This week I brewed another 10 gallon batch and even increased my base malt by 2 pounds and adjusted my water accordingly. My efficiency dropped to 66%. I mill my grains at the LHBS and they told me a few years ago the mill is set at a credit card gap. I have always double milled my grain and have had good results. I know over the years the finer the mill the better for BIAB. Unless they changed their setting something has changed. These are the first two 10 gallon batches I have brewed. I know some may feel if the beer is good don't worry, but I'm working hard for consistency and for some reason that has changed.

Here are some specifics on my system and last process.

I'm using a 20 gallon old portable whirlpool tub that is 25" x 13" x 15" deep so it's an oval for my E-kettle.

I have extremely hard water so I have a RO Filter and normally use 80 to 90% RO water and top off with my well water. I use Bru'n Water for finding a profile along with Beer Smith and my software program.

I stir every 15 minutes or so and recirculate.

My mash thickness is 2.6 Qts./Lb.

My grain bill was 21.5 lbs.

Target pH was 5.5 but was low and adjusted up to 5.3 at 15 minutes in.

Mash temp was 153 and with my system maintain that the entire 60 minutes.

I use two boards and squeeze clamps to squeeze the bag and have great success with adding a few gravity points and wort back into the kettle.

Boil for 60 minutes and hit all my water levels and for the most part my gravity but was low on this batch. Expected OG 1.059. Mine came in at 1.052 and I mentioned earlier BH efficiency dropped to 66 % according to Beer Smith. I did double check all my entries into Beer Smith.

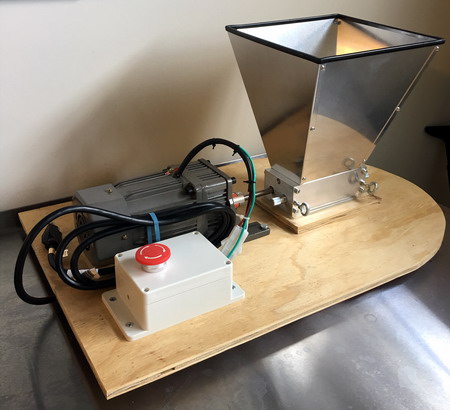

Not sure why my 10 gallon batches are dropping in efficiency. I included a picture of the spent grains but not sure if you can tell if it's still too coarse.

Thanks for your help and suggestions.

Bill

I love stouts, porters and lately brewing bourbon stout. This spring I wanted to brew a beer that was a good summer beer. Something light but yet have some body better than the Bud, Coors, Miller and Bush Lights. Well after tying many suggested flavors settled in on a Cream Ale.

Well my first recipe was spot on for what I wanted and I have brewed 4 batches. The first two were 5 gallon batches. They both came in at 83% BH efficiency which is where most of my beers come in at. I decided to increase my batch to a 10 gallon batch and although it was the same taste, my efficiency dropped to 75 %. Not bad but puzzling. This week I brewed another 10 gallon batch and even increased my base malt by 2 pounds and adjusted my water accordingly. My efficiency dropped to 66%. I mill my grains at the LHBS and they told me a few years ago the mill is set at a credit card gap. I have always double milled my grain and have had good results. I know over the years the finer the mill the better for BIAB. Unless they changed their setting something has changed. These are the first two 10 gallon batches I have brewed. I know some may feel if the beer is good don't worry, but I'm working hard for consistency and for some reason that has changed.

Here are some specifics on my system and last process.

I'm using a 20 gallon old portable whirlpool tub that is 25" x 13" x 15" deep so it's an oval for my E-kettle.

I have extremely hard water so I have a RO Filter and normally use 80 to 90% RO water and top off with my well water. I use Bru'n Water for finding a profile along with Beer Smith and my software program.

I stir every 15 minutes or so and recirculate.

My mash thickness is 2.6 Qts./Lb.

My grain bill was 21.5 lbs.

Target pH was 5.5 but was low and adjusted up to 5.3 at 15 minutes in.

Mash temp was 153 and with my system maintain that the entire 60 minutes.

I use two boards and squeeze clamps to squeeze the bag and have great success with adding a few gravity points and wort back into the kettle.

Boil for 60 minutes and hit all my water levels and for the most part my gravity but was low on this batch. Expected OG 1.059. Mine came in at 1.052 and I mentioned earlier BH efficiency dropped to 66 % according to Beer Smith. I did double check all my entries into Beer Smith.

Not sure why my 10 gallon batches are dropping in efficiency. I included a picture of the spent grains but not sure if you can tell if it's still too coarse.

Thanks for your help and suggestions.

Bill