Gregory T

Well-Known Member

- Joined

- Mar 7, 2018

- Messages

- 215

- Reaction score

- 64

I am looking for info on how others brew Trappists and their results @RPIScotty

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I started pitching around 500 billion cells in my Tripels 5.5 gallons, 1.078. Which seems close to your 1.25-1.40 unless I’m not reading something right again.

I don’t use oxygen. I use a Venturi and an air pump for about 10 minutes. I should probably get a DO meter soon.

I like the taste of the first one, but it turned out darker than I thought. It was darker than the St Bernardus Tripel and lighther than Taxman’s. I substituted the 1 lb of Munich for 1 lb of Vienna. I just moved it to cold crash

I step mash at 113°F, 135°F, 145°F, and 158°F for my Tripel. I pitch slightly above the 1.0 m/ml/°P. The first rest is for beta glucanase, the second for proteinase are to help with clarity

If I just calculated it correctly, I would need to pitch 8 packs of Lallemand Abbaye dry yeast for a 26 Liter batch of Dubbel.

If I just calculated it correctly, I would need to pitch 8 packs of Lallemand Abbaye dry yeast for a 26 Liter batch of Dubbel.

I'm pretty sure Lallemand Abbaye it listed at 5 billion cells per gram, so at 11 grams in a pack that is 55 billion cells.

55B_cells/26L/17.3P = 0.1223

0.1223⁻¹ = 8.17

So a bit more than 8 packs to achieve 1.00 M/mL/P

5.00 B/g is the MINIMUM cell count at the best by date.

My correspondence with Lallemand indicated that for a new pack, Abbaye is around 9-10 B/g.

I'm pretty sure Lallemand Abbaye it listed at 5 billion cells per gram, so at 11 grams in a pack that is 55 billion cells.

55B_cells/26L/17.3P = 0.1223

0.1223⁻¹ = 8.17

So a bit more than 8 packs to achieve 1.00 M/mL/P

I'm pretty sure Lallemand Abbaye it listed at 5 billion cells per gram, so at 11 grams in a pack that is 55 billion cells.

55B_cells/26L/17.3P = 0.1223

0.1223⁻¹ = 8.17

So a bit more than 8 packs to achieve 1.00 M/mL/P

So its either 4 packs direct pitched

or a 17.3P starter of 2L volume developed from 1 pack.

What temperature do you pitch it at and how long do you leave it before packaging/cold crashing? Also do you apply any heat after It starts cooling down3787 is the most user friendly Trappist strain available.

What temperature do you pitch it at and how long do you leave it before packaging/cold crashing? Also do you apply any heat after It starts cooling down

Due to mashing in a cooler, and due to raising temperature via the addition of boiling water, I find it practical to attempt only two temperature hold steps during the mash. Given this, I'm thinking along the lines of 136 degrees F. for 15 minutes, followed by 150 degrees F. for 45 minutes. Will this bring any benefit, or should I just do a single infusion mash? And if there is benefit to be gained, are 136 and 150 degrees the two best temperatures to shoot for?

Due to mashing in a cooler, and due to raising temperature via the addition of boiling water, I find it practical to attempt only two temperature hold steps during the mash. Given this, I'm thinking along the lines of 136 degrees F. for 15 minutes, followed by 150 degrees F. for 45 minutes. Will this bring any benefit, or should I just do a single infusion mash? And if there is benefit to be gained, are 136 and 150 degrees the two best temperatures to shoot for?

...One around 144°F for 40...

This is a well timed thread. I’ve got my first tripel lined up to brew soon. Beersmith set to 0.75m/ml/*P was figuring 334.3 billion cells for 1.087 OG. Sounds like I need to step it up to 1.0m/ml/*P, or should I go 1.25? Either way, I’m gonna need to do a 2 step starter, or get a bigger flask.

A damned thorough answer. Appreciate the info.Well, let's keep a few things in mind:

1.) There is a rhyme and reason to manipulating fermentation parameters and you (not you specifically, the Royal You, meaning US) should understand the mechanics before diving in;

2.) If you want to ferment without temperature control, you should pitch cool, around 64 F;

3.) I pitch in the 1.25-1.50 M/ml/P range because I am going to undercut O2 and limit Zn to 0.3 to try and stunt yeast growth;

4.) I limit O2 to < 8 ppm

All of this is designed to let me ferment without temperature control so the yeast naturally rises into the 70s. I want to be able to do this because I think clamping down and restricting temperature is not what the yeast want. Especially 3787. I want to limit yeast growth so my beer doesn't generate a ton of undesirable higher alcohols early on while still producing a desirable ester profile.

I'd like to add that I've played around with different base malts including floor-malted grains.

In terms of mashing, I'm fairly certain most of the trappist breweries are doing step mashes, but at the homebrew level I'm not sure that it's worth the trouble. I've certainly achieved better efficiency when I step mash with floor-malted grains but with how yeast-driven most of these styles are I find that many of the subtleties get lost. That's not to say that I'm going to discourage others from trying to replicate the process, not at all. Heck, one of these days I plan on doing a full triple deccoction for a Czech pils just for the sake of doing it.

For the most part I mash low, around 145-148F and as RPIScotty said I pitch in the mid 60s. I don't really use any temp control so depending on the time of year my ferment can reach up to 80F at its peak, not that I'm complaining about the results. I tend to not do this during the winter though as the first time I brewed a tripel in the winter my ferm never rose above 64 and I got all the phenolic character with almost none of the esters. I didn't realize my basement was in the low 50s.

The takeaway is that trappist beers in general, and Belgian beers as a whole really benefit from at least a basic understanding of fermentation mechanics. Temp control, ester production, all that good stuff.

I can't believe I forgot about hops. Since most of my hop additions are FWH I just use a high alpha variety such as Magnum or Polaris.

Hey, if it works for you I say don't mess with success. Attenuation and foam have never been issues for me as something about my process provides super stable foam.I find step mashing is important for 3 reasons that don’t necessarily have a direct result on flavor: Attenuation, Body and Foam.

β rest(s) ensure complete conversion and supreme fermentability.

α rest ensures full body even in light of high Attenuation.

Sustained mash out guarantees foam positive glycoproteins for that mousse like head.

For me, a Trappist inspired Ale is 97% fermentation, 2% Mashing and 1% all the other stuff.

I find step mashing is important for 3 reasons that don’t necessarily have a direct result on flavor: Attenuation, Body and Foam.

β rest(s) ensure complete conversion and supreme fermentability.

α rest ensures full body even in light of high Attenuation.

Sustained mash out guarantees foam positive glycoproteins for that mousse like head.

For me, a Trappist inspired Ale is 97% fermentation, 2% Mashing and 1% all the other stuff.

Tripel - Beta rest at 148 F (60 min) - 80.8% AA

Tripel - Beta rest at 142 F (40 min) - Alpha rest at 158 F (20 min) - Mash out at 168 F (10 min) - 87.3% AA

Only other difference was 1 used 1 lb Vienna and 1 used 1 lb Munich

Brauwelt released a 2 part series on mashing a few years ago. Here are some of the relevant graphs (including the correlation between Hartong Index (VZ45) and Gelatinization (more on this later)):

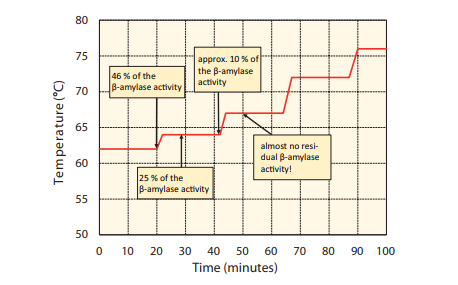

I. Beta Activity - Temperature vs. Time

View attachment 630655

(Note the relevant times above: 62 C (143.6 F), 64 C (147.2 F) and 67 C (152.6 F))

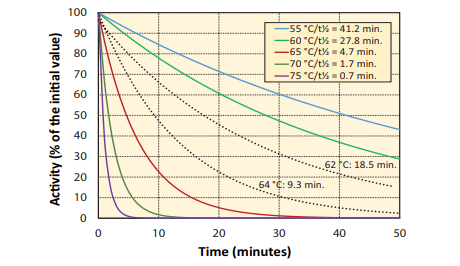

II. Beta Activity - % of Activity vs. Time

View attachment 630656

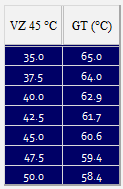

III. Correlation Between Hartong Index and Gelatinization Temperature

View attachment 630662

So in light of the above let's analyze your batches. I'm assuming that other than the changes in fermentables that all else was equal? Yeast? Aeration? Ferm temps? Let's assume that to make a point.

Your first batch had a single rest at 148 F (64.4 C) for 60 min. Take a look at the first graph. What are we looking for? Well, we see that at temperatures at or above 64 C, we are missing out on a considerable amount of Beta Amylase activity.

Is it an On/Off switch? No but we are bypassing it altogether at temperatures > 64 C. One of the main reasons, whether intentional or not, that brewers are recommended to mash longer at temperatures around 148-149 F is because of this. You need to overcome the loss in major Beta activity.

Now look at the second graph. What is that telling us? It's showing us that the half life for Beta Amylase activity is rather short at your chosen temperature.

So lower Beta Amylase activity at the chosen temperature is a function of the temperature you choose and the 1/2 life of the activity at that temperature.

Now 80.8% is by no means a terrible amount of attenuation for most styles but I like to keep Original Extract low in these beers and get high AA (85% or greater).

At 148 F, I doubt Gelatinization temperature was an issue so we'll skip that for now.

First things first: How fast did you ramp the temperature here? Have you ever heard of the oft quoted 1 C/min ramping criteria for stepping between rests? Many people try to rationalize what it may be used for but we'll talk about it in a minute.

Let's analyze Beta Amylase temperature you chose here. Looking at the first graph we see that for temperatures at or around 62 C (your temp was 61.1), you'll get around 46% of the total Beta Amylase activity. Looking at the second graph, you see that for this same temp, the Beta Amylase half life is much longer at almost 20 minutes. So holding this low rest for 40 minutes gives a large amount of Beta activity for longer.

Which base malts were you using? The reason I ask has to do with the third graph and the table below:

View attachment 630661

Do you measure your gravity throughout the mash? One of the reasons the Gelatinization temperature for a specific malt is important is for the purposes of extract. If the starch cannot be broken down readily and absorb water, you'll see a hit in extract, especially with only a single Beta rest.

Your Beta temperature was so low that it would be in the "danger zone" for Gelatinization temperatures IMO, but if you didn't see any ill effects from a gravity standpoint I guess it was a non issue.

The reason I bring up ramp rate is that it is one of the often overlooked advantages of step mashing. Say you end your 142 F rest and begin ramping to Alpha. If you are doing it at 1 C/min, you'll actually step through all the temperatures in between.

I would suggest you go higher and longer for the Alpha rest: 162 F for 30 minutes.

87.3% is a great value for attenuation if you designed the recipe around that, i.e. I always keep Original Extract lower and let attenuation drive the ABV.

Same amount of sugar?

7 lbs German pils

7 lbs Belgian pils

1 lb Candi syrup clear

1 lb Vienna Malt (Munich in 1st batch)

0.5 lb flaked barley

They were both pitched at a little over 500 billion cells of WLP500

This was stepped using boiling additions so the temperature change was basically immediate

This was my first time using a pump for recirculation

It was a BIAB and hit 93.9% mash efficiency

I’ll have to start measuring gravity throughout

I have since added a HERMS coil and another pump to whirlpool the HLT/HERMS coil. I haven’t used it yet

From my research, there is a little debate. however the one that makes since to me is the HERMS outlet temperature will be my main concern. That makes sense to me in order to not overheat the enzymes in the wort Please addd any thoughts on this

I love those graphs. The 1°C/min makes sense. I will try to do that this weekend.

I plan to make 3 Blondes over the next few weeks. While they aren’t my Tripel, I think it will allow me to get up to speed on the new equipment

I will try 162°F next time. I’m debating keeping the 113°F and the 135°F rests just because I enjoy it. Any harm that might do?

I find step mashing is important for 3 reasons that don’t necessarily have a direct result on flavor: Attenuation, Body and Foam.

β rest(s) ensure complete conversion and supreme fermentability.

α rest ensures full body even in light of high Attenuation.

Sustained mash out guarantees foam positive glycoproteins for that mousse like head.

For me, a Trappist inspired Ale is 97% fermentation, 2% Mashing and 1% all the other stuff.