Indeed, anyone who has the classic style regulator (PSI) and a flow meter that reads in L/m. Could you give us an idea of what PSI correponds to a given flow rate, and be sure to mention whether you have a 0.5 or a 2 um stone. Then we will be able to get into the ballpark pressure without having to invest in a flowmeter or a DO meter. thanks for your input!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aerating with Oxygen

- Thread starter pilotdane

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I am between the medical one previously posted or the cheapy welding one from HF, I figure I can get it for $24 after their 20% coupons they hand out like candy.

Anyone ever used this one?

- Harbor Freight Tools - Quality Tools at the Lowest Prices

Anyone ever used this one?

- Harbor Freight Tools - Quality Tools at the Lowest Prices

I use a similar regulator. I do not read the PSI, I just adjust from zero up until the bubbles are what I want. I think that one will work fine for you.

Be sure to turn the tank off when you are done.

David

Be sure to turn the tank off when you are done.

David

JKoravos

Well-Known Member

Indeed, anyone who has the classic style regulator (PSI) and a flow meter that reads in L/m. Could you give us an idea of what PSI correponds to a given flow rate, and be sure to mention whether you have a 0.5 or a 2 um stone. Then we will be able to get into the ballpark pressure without having to invest in a flowmeter or a DO meter. thanks for your input!

It's highly depending on your system. For one setup 2 psi could be 1L/min, for another it could be 0.1L/min.

I think you will find it hard to apply the correct amount of o2 consistently. Most people set the dial to only 2-3 psi when injecting o2... that will be pretty hard to read on this scale.

I forgot I got a secondary regulator and took off the tank connection piece so I think I will get the medical one with the l/m gauge and plug in the 540 connection if I need to.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Aerating worth prior to fermentation is good. You can do this by splashing the worth around, shaking the bucket, using an aquarium pump, or adding oxygen.

Using oxygen is the fastest way to do it.

There is only so much oxygen you can get into the wort with each method, pure o2 provides the ability to get up to 12ppm into the wort where most of the others max out at about 8ppm. At least that is what the latest article in BYO mentions.

Boerderij_Kabouter

Well-Known Member

Could I use one of these:

Dwyer Instruments

With one of these:

Oxygen Regulator - For Disposable Tanks w/Barb | MoreBeer

to control my O2 flow?

I want to use this setup with an inline Oxygenation setup. My thought was I could just crack open the "regulator" then control the flow rate with the Dwyer meter. Feasible?

Dwyer Instruments

With one of these:

Oxygen Regulator - For Disposable Tanks w/Barb | MoreBeer

to control my O2 flow?

I want to use this setup with an inline Oxygenation setup. My thought was I could just crack open the "regulator" then control the flow rate with the Dwyer meter. Feasible?

Wyeast Laboratories. Customer Service FAQs

Here is some good information with some about oxygenation.

Here is some good information with some about oxygenation.

CoopDvr

Active Member

I am between the medical one previously posted or the cheapy welding one from HF, I figure I can get it for $24 after their 20% coupons they hand out like candy.

Anyone ever used this one?

- Harbor Freight Tools - Quality Tools at the Lowest Prices

I'm new to brewing, but experienced with gases having worked in underwater construction for 10 years. That said, I would be extremely wary of an o2 reg from Harbor Freight. I strongly recommend paying the extra money to get a reputable brand (Victor, Meco, etc).

O2 is very dangerous and can explode when not handled properly or when regulated through crappy equipment - trust me, I've seen it. It's probably also a good idea for all of you handling oxygen to spend about 10 minutes online reading about keeping your gear "oxygen clean".

Be safe.

chemman14

Well-Known Member

does oxygenation help with low attenuation issues or just lag time?

jackbilbow

New Member

If you pumped pure oxygen with a 2 micron stone for 43 seconds, .... When dissolved in 5 gallons or 18.8 liters of wort, this results in a concentration of 43 ppm. ... The thing to do is to measure the amount of O2 you add by time and flow rate. ...

oldschool

Well-Known Member

Wyeast Laboratories. Customer Service FAQs

Here is some good information with some about oxygenation.

I was just about to recomend this link to you all. In college chemistry we learned that oxygen is insoluble in water so it is difficult to get any O2 in solution. I think that any O2 bubbled in would be doing the job fine...and that goes back to your pitch rate.

JKoravos

Well-Known Member

Before I had a DO meter, I was trying to figure out appropriate oxygenation times, and so contacted Wyeast for more details on their oxygenation experiment. On their website, they show different levels of oxygenation that can be achieved with different methods. They said that 12ppm can be obtained using pure oxygen for 60 seconds, but they didn't specify the flow rate. Greg Doss helpfully responded to my question and said that, for these experiments, they used a flow rate of 3.5 LPM through a 2 micron stone.

So, to oxygenate 5 gallons to 12ppm, you would oxygenate for 60 seconds with a flow rate of 3.5 LPM using a 2 micron stone.

If you don't have a DO meter, your best bet is choose a consistent method of aeration/oxygenation and then vary your pitching rate in order to achieve the desired results (since, in general, oxygenation and pitching rate interact with each other to produce the total amount of yeast growth).

Thanks for taking the time to follow up with WYeast on this. That's a very valuable piece of information, right there.

bbognerks

Well-Known Member

Necro Bump.

This is the only thread where I could find flow rates to achieve the proper saturation of o2 in wort. I have an inline set up, so I am trying to figure out what flow rate I need to use for continuous o2 diffusion.

I took this post post1520001 from this thread and scaled it back.

Using a 2 micron stone.

For 5 gallons:

3.5 lpm for 1 min

1.75 lpm for 2 min

.875 lpm for 4 min

.4375 lpm for 8 min

So for 10 gallons it should be

7 lpm for 1 min

3.5 lpm for 2 min

1.75 lpm for 4 mins

.875 lpm for 8 mins

By my thinking, if it takes 8 minutes to pump my wort through my plate chiller and into the fermentor, I would need a flow rate of .875lpm to achieve 12ppm into 10 gallons. Does this sound right?

This is the only thread where I could find flow rates to achieve the proper saturation of o2 in wort. I have an inline set up, so I am trying to figure out what flow rate I need to use for continuous o2 diffusion.

I took this post post1520001 from this thread and scaled it back.

Using a 2 micron stone.

For 5 gallons:

3.5 lpm for 1 min

1.75 lpm for 2 min

.875 lpm for 4 min

.4375 lpm for 8 min

So for 10 gallons it should be

7 lpm for 1 min

3.5 lpm for 2 min

1.75 lpm for 4 mins

.875 lpm for 8 mins

By my thinking, if it takes 8 minutes to pump my wort through my plate chiller and into the fermentor, I would need a flow rate of .875lpm to achieve 12ppm into 10 gallons. Does this sound right?

dstar26t

If it's worth doing, it's worth overdoing

sleepystevenson

Well-Known Member

According to Jamil and Chris White's new Yeast book - Pg 78-79: For the average wort and yeast pitching rates, the proper amount of dissolved oxygen is 8 to 10 parts per million. This can be achieved (9.2 ppm) in a 5 gal. batch with 60 seconds of pure O2 at a flow rate of 1 liter per min using a .5 micron stone.

Just an FYI.

That book rocks - I highly recommend it.

Just an FYI.

That book rocks - I highly recommend it.

dstar26t

If it's worth doing, it's worth overdoing

Looks like my data is accurate

sleepystevenson

Well-Known Member

Yep! Nicely done!

Yes that is great data indeed but it is still not helpful if you do not have a flow meter. I wonder if anyone who has a flow meter can give us a ballpark pressure to work with. I use the more beer 0.5 micron stone which is mounted on a piece of stainless tubing about 2 foot long, and then there is another 2-3 feet of tubing connecting that to the tank. I realize flow rate will change with the length and diameter of the tubing but I suspect it would not change that much if someone has an extra foot of tubing or a slightly smaller ID of tubing.

How did you measure the actual O2 saturation? Are you using a 0.5 or 2 micron stone?

dstar26t

If it's worth doing, it's worth overdoing

This meter and a .5 micron stone.

bctdi

Well-Known Member

According to Jamil and Chris White's new Yeast book - Pg 78-79: For the average wort and yeast pitching rates, the proper amount of dissolved oxygen is 8 to 10 parts per million. This can be achieved (9.2 ppm) in a 5 gal. batch with 60 seconds of pure O2 at a flow rate of 1 liter per min using a .5 micron stone.

Just an FYI.

That book rocks - I highly recommend it.

So would it be accurate to say that if I use a 2 micron stone I could use a flow rate of .25 LPM for 60 seconds to achieve the same amount of O2 in 5 gallon batch?

bbognerks

Well-Known Member

No, since the pore size in the stone is bigger, it won't as easily dissolve into the wort. It's making bigger bubbles. If anything you would have to increase the flow to keep the same time. Earlier in this topic, Wyeast claims that for a 2 micron stone, 60 seconds at 3.5lpm would yield 12ppm. So probably 2.5 - 3lpm for 10ppm.

I also wanted to better quantify my dissolved O2 with a O2 meter. I bought a Milwaukee MW600 DO meter to test my dissolved oxygen. I am using a Dakota low flow O2 regulator (0-1.3 L/min).

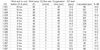

I calibrated the meter to instructions. On my first batch (an IPA) at 74 degrees and an OG of 1.071 and 11 gallons in the conical with a 2 micron stone I got the following readings (each reading was stacked on top of the previous reading, so the 2nd reading is at 6 min and the last at 9 min):

3 min @ 0.5 L/min = 3.5 ppm

3 min @ 1 L/min = 6.4 ppm

3 min @ 1 L/min = 9.2 ppm

So, that works out to 9 min @ .83 L/min for 9.2 ppm at 74 degrees in an 11 gallon batch of 1.071 OG wort.

Next time I'll just go 9 min @ 1 L/min, expecting a little closer to 10 ppm.

I calibrated the meter to instructions. On my first batch (an IPA) at 74 degrees and an OG of 1.071 and 11 gallons in the conical with a 2 micron stone I got the following readings (each reading was stacked on top of the previous reading, so the 2nd reading is at 6 min and the last at 9 min):

3 min @ 0.5 L/min = 3.5 ppm

3 min @ 1 L/min = 6.4 ppm

3 min @ 1 L/min = 9.2 ppm

So, that works out to 9 min @ .83 L/min for 9.2 ppm at 74 degrees in an 11 gallon batch of 1.071 OG wort.

Next time I'll just go 9 min @ 1 L/min, expecting a little closer to 10 ppm.

Kingkisner

New Member

Does anyone know what kind of saturation i should expect to have if I were to pressurize o2 in my keg? Or is that not even recommended?

I'm always interested in discussions about oxygenation.

As my current understanding rests, the following statement is true:

So, if I take the time to make an appropriately sized starter, I should be able to ferment a 1.080+ wort with no undesirable side effects, and no added O2.

I have an O2 setup, but have never used it. So far I have yet to create a wort that I can't start with < 12 hours lag and ferment to completion regardless of gravity. It just takes the correct number of cells.

What do you guys think? Is this true, or would I see improvement by adding O2 to my process?

As my current understanding rests, the following statement is true:

If you pitch enough cells to properly ferment a wort with no need for growth in the wort, then no more oxygen is required than what is absorbed ambient during the transfer to carboy, regardless of the SG of the wort.

So, if I take the time to make an appropriately sized starter, I should be able to ferment a 1.080+ wort with no undesirable side effects, and no added O2.

I have an O2 setup, but have never used it. So far I have yet to create a wort that I can't start with < 12 hours lag and ferment to completion regardless of gravity. It just takes the correct number of cells.

What do you guys think? Is this true, or would I see improvement by adding O2 to my process?

i just put a rubber stopper on the top of the carboy and shake the crap out of it. never had a problem with fermentation. dose using the O2 really make a big difference or is that only in bigger batches that you cant pick up and shake?

orangehero

Well-Known Member

Yeast growth and oxygenation factors all have an effect on the flavor profile of the finished beer. The goal isn't simply to get enough yeast whether in a starter or the wort.

Similar threads

- Replies

- 2

- Views

- 297

- Replies

- 2

- Views

- 621

- Replies

- 10

- Views

- 779

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)